عنا

مرحبا هل يمكنني مساعدتك؟

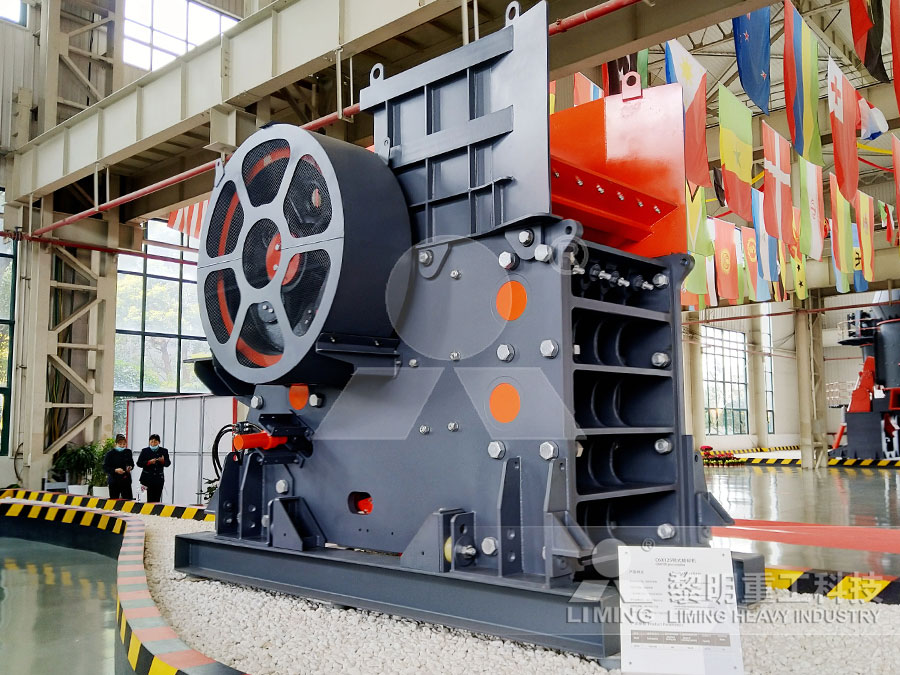

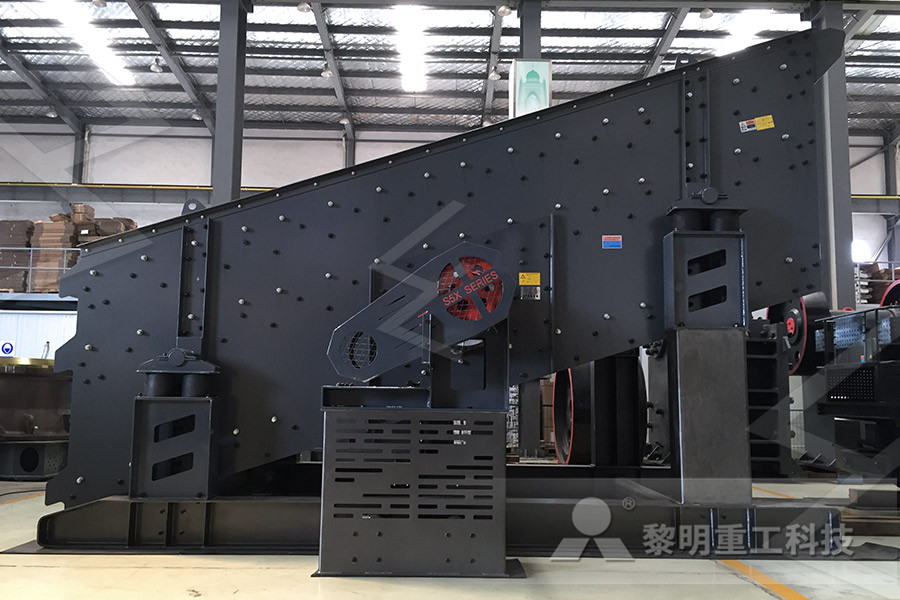

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

iron ore crusher primary

2020-01-26T01:01:42+00:00

The six main steps of iron ore processing Multotec

Six steps to process iron ore 1 Screening We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage A 2022年1月1日 The operation processes up to 6000 t/h of iron ore (itabirites) coming from Conceição and Dois Córregos Mines (Jesus et al, 2015) The primary crushing stage Comminution and classification technologies of iron oreThe primary coal crushers may be of different types such as: (1) coal jaw, (2) coal hammer, and (3) ring granulator Secondary coal crusher: Used when the coal coming from the Primary Crusher an overview ScienceDirect Topics

Challenges and opportunities in the iron ore

2019年8月8日 According to the current production level, it can be supplied for 400 years Iron ore resources are mainly reserved in more than10 countries, and 90% of proven reserves are distributed in10 countries and 2022年8月18日 This paper presents an economic analysis of a minetocrusher model to estimate and minimize the operating expenses of an openpit iron mine located in northern Brazil The activities at this truckless A MinetoCrusher Model to Minimize Costs at a 2021年3月25日 There are several types of primary crushers, including: Gyratory Crushers Jaw Crushers Hammermills Horizontal Shaft Impact Crushers Sizers Roll Crushers Cone Crushers FeederBreakers Gyratory What Type of Crusher Is Best for Primary

Iron Ore Crusher Mining, Crushing, Grinding,

2011年10月15日 Iron ore processing can be a procedure that contains explosions, shoveling, moving, crushing, grinding, pelletizing etc Iron ore processing provides a range of coarse sizing that may produce material 2013年7月23日 primary iron ore crusher India – kefid Mineral Processing Equipment primary iron ore crusher India The mostly used crushers and grinding mills in iron ore primary crushing to process iron ore Mining Quarry PlantThe primary crusher converts the feed size to one that is acceptable to the secondary crusher granite, basalt, river gravel, bauxite, marble, slag, hard rock, limestone, iron ore, magazine ore, etc, within a pressure resistance strength of 200 MPa Jaw crushers are characterized for different features such as a simple structure, easy Crusher an overview ScienceDirect Topics

McLanahan Mineral Sizers

McLanahan Mineral Sizers are designed to process a variety of materials, including copper, iron ore, gold, nickel, lithium/spodumene, coal, potash, phosphate and other hard rock and soft, noncoal minerals They can be 2021年3月25日 Hammermills can be used as a primary crusher in many types of aggregate and industrial applications, including limestone, marble, shale, gypsum, phosphate, bauxite, aluminum dross, uranium, cryolite, What Type of Crusher Is Best for Primary 2020年10月1日 1 Introduction The gyratory crusher is widely used in primary crushing of metal ore such as iron ore and copper ore due to its high productivity and large feed inlet [[1], [2], [3]]In recent years, with the growth of the world's population, the development of urbanization and the improvement of living standards, the demand for the ore continues Simulation and optimization of gyratory crusher

Primary Crusher Selection Design 911 Metallurgist

2015年12月23日 Primary Crusher Selection Design , degradability and it being prone to dusting or not The crusher capacities given by manufacturers are typically in tons of 2,000 lbs and are based on crushing limestone weighing loose about 2,700 lbs per yard3 and having a specific gravity of 26 Wet, sticky and extremely hard or tough feeds will tend to 2019年8月8日 The iron ore crusher price; Different iron ore has different features According to these features, the crushers are made of different materials Primary crushing; The jaw crusher is generally used in the crushing process of iron ore The jaw crusher is a traditional and reliable coarse crushing equipment, and its application range Challenges and opportunities in the iron ore crusher market2015年1月1日 This chapter reviews current iron ore comminution and classification technologies and presents some examples of flowsheets from existing operations New trends and advances in comminution technologies are presented and discussed, particularly with regard to the impact on energy, operating, and capital costs Gyratory crusher: Developments in iron ore comminution and classification

Crushing 101 – Different types of crushers for distinctive needs

2020年12月17日 Jaw crushers can be divided into two basic types, single and double toggle In the single toggle jaw crusher, an eccentric shaft is on the top of the crusher Shaft rotation, along with the toggle plate, causes a compressive action A double toggle crusher has two shafts and two toggle plates The first shaft is a pivoting shaft on the top of 2011年7月27日 Ore processing The lump ore and sinter fine products extracted from the Brockman 4 are transported to the processing plant through 16 Komatsu 830EAC and two Komatsu 730E haul trucks The plant boasts a primary jar crusher, two secondary cone crushers, a six bin screening building and gravity separation system Processing can be Rio Tinto Brockman 4 Iron Ore Mine, Pilbara Mining 2009年1月1日 Also, equipment like ball mill is used at the final stages of grinding Among the comminution and grinding equipment, HPGR is increasingly utilized as tertiary crusher or primary mill because of (PDF) Processing of Magnetite Iron Ores–Comparing

Ore Crusher PE Series Jaw Type Ore Crusher

Using Jaw crusher in Primary Crushing: In the primary crushing of iron ore, Aimix, a professional supplier of any kind of crushers, not only have the best iron ore crusher price but also has the best quality PE400600jaw 2023年3月13日 Once the primary crushing stage is complete, the smaller iron ore pieces are further crushed using a secondary crusher The secondary crusher reduces the size of the ore particles to 052 cm in How iron ore is crushed? LinkedInProduct Introduction JXSC jaw type rock crusher is usually used as a primary crusher and secondary crusher to reduce the size of mediumhard materials to smaller physical size Jaw rock crushers are capable of Jaw Crusher Primary Crusher in Mining

What is the process of crushing copper ore? LinkedIn

2023年3月16日 The process of crushing copper ore typically involves a series of steps Here is a general outline of the process: Mining: Copper ore is typically mined from an openpit mine or underground mine 2016年2月24日 crusher’s discharge opening, as the production continues through an online coarse size analysis of the crushed product (digital image analyses) Dance, A 2001) • More attention is being paid to the impact on crushing circuit design caused by variations in ore characteristics, size distribution, moisture content, ore grade and climaticCrushing Plant Design and Layout Considerations 911 Which hammer crusher can crush iron ore (100TPH)? In this case, we recommend the use of a PCZ1308 heavy hammer crusher with a feed size of 930x650mm, the feed particle size is less than 600mm, the motor power is 4P 132Kw, and the processing capacity of the equipment is 100180t/h A pitportable primary crusher can be an economically sound Rock Crusher Eastman Rock Crusher

Crushing

From large primary jaws and gyratories to cone and impact crushers for tertiary and quaternary finishing, equipment is manufactured to meet your material reduction requirements The crushers are built to perform with the lowest cost per ton, featuring a unique combination of crusher cavity design, crushing forces, reliability and safety2012年2月6日 Iron Ore Crushing and Grinding Machines The most commonly used crushers and grinding mills in iron ore crushing and grinding process for iron ore mining are jaw crusher, cone crusher, hammer crusher and ball mill, ultrafine grinding mill, etc In iron ore mining, miner usually choose a complete iron ore crushing plant for metallurgyIron Ore Crushing and Grinding MachinesCSDN博客2012年3月26日 Channar iron ore mine is situated 17km southeast of Paraburdoo mine in the province of Pilbara, a region in Western Australia It is 60% owned by Rio Tinto Iron Ore and 40% by Chinese mining company Sinosteel The processing plant has a primary crusher, screening plant and gravity separation system Two stages of crushing are Channar Iron Ore Mine, Pilbara Mining Technology

Energy and Environmental Profile of the US Mining

2013年11月8日 The most important iron oreforming minerals are: • Magnetite Magnetite (Fe3O4) forms magnetic black iron ore There are large deposits of Following blasting, the fragmented ore is loaded on a mining truck and hauled to the crusher for primary crushing Many mines employ two to three stages of crushing Some mines have the2012年4月1日 Marandoo iron ore mine is situated 35km east of Tom Price in the province of Pilbara, in Western Australia It is 100% owned and operated by Hamersley Iron, a wholly owned subsidiary of Rio Tinto Iron Marandoo Iron Ore Mine, Pilbara Mining 2014年5月20日 Iron ore western centeral eastern Exploration Detail: 26km 8km This mine is one of the largest mineral areas in Iran, also considered to be one of the Middle East’s richest deposits it is divided in three major zones; western, central and eastern These iron ore deposits contain a total geological resource of 12 billion tons of mostly magnetite Sangan Iron Ore Mines(SIOM) M E S T E E L

Karara Iron Ore Mine Mining Technology

2010年3月24日 The mine is one of the few magnetite projects currently under development in Australia Trains are used to transport iron ore form mines to the Western Australian coast Of the 14 billion tons of Sishen mine is wholly owned by Sishen Iron Ore Company (Pty) Ltd SIOC is owned by Exxaro (204%), Kumba Iron Ore Ltd (754%), and other (42%) Kumba Iron Ore Ltd is 697% owned by AA plc loaded by electric and diesel (rope and hydraulic) shovels and hauled by trucks to either the primary crusher, highgrade or lowgrade stockpiles or Major Mines Projects Sishen MineThe Ally to Your Iron Ore Processing Plant Here at Benetech, we dedicate our greatest resources to resolving your daily challenges in bulk material handling To discuss how you can reinforce a safer, more productive iron ore facility, contact us at (630) 8441300 to speak with a specialist Posted in Dust ControlIron Ore: From Mining to Processing to Dust Control

Simheuristicbased decision support system for

2020年9月1日 Simheuristicbased decision support system for efficiency improvement of an iron ore crusher circuit Author links open overlay panel Mário S Santos a b, Thomás VB Pinto a, Ênio Trucks transport ore extracted from the mine and unload it into the primary crusher The primary crusher reduces ore blocks with sizes of up to 1 m to a 2023年2月17日 Here are some common types of equipment used in iron ore crushing: 1 Jaw Crusher: This is a primary crusher that is used for coarse crushing It has a fixed jaw plate and a movable jaw plate, and What equipment is used in iron ore crusher? LinkedInGyratory and Cone Crusher In Mineral Processing Design and Operations (Second Edition), 2016 51 Introduction Gyratory crushers were invented by Charles Brown in 1877 and developed by Gates around 1881 and were referred to as a Gates crusher [1]The smaller form is described as a cone crusher The larger crushers are normally known as primary Gyratory Crusher an overview ScienceDirect Topics

A MinetoCrusher Model to Minimize Costs at a

2022年8月19日 iron ore mine in Brazil The model correlated the mine phase operating costs with the P80 size resulting from blasting material An economic database and key performance indicators (KPIs) were collected for the unit operations of drilling, blasting, loading and primary crushing in 2019, and they were statistically processed to estimate 13 小时之前 Iron ore is the primary raw material used to make steel Steel is strong, longlasting and costefficient – making it perfect for everything from washing machines to cars, bridges and skyscrapers Our primary crusher uses a similar ‘removable’ design, allowing our teams to service it from the top – rather than performing higherrisk Iron Ore Rio Tinto2022年11月21日 crusher configuration The feed material should be at least 20% smaller than the width of the feed open ing Arrangement drawing with fitting dimensions and loads on request Large feed opening 3,080 x 1,675 mm Jaw gyratory crusher for underground iron ore mining and the crushing chamber of a BK 6375 in a stationary copper ore plantIndustrial Solutions Gyratory crushers ThyssenKrupp

Jaw Crusher Eastman Rock Crusher

Jaw crusher is a compression style rock crusher, as a primary crusher to crush limestone, cobblestone, cobblestone, quartz in the mining, quarry, aggregate, etc Skip to content basalt, iron ore, granite, shale, 2023年5月27日 While the cone crusher is more suitable for hard rocks and ores, such as iron ore, granite, pebble Besides, a cone crusher is not suitable for crushing viscous materials that contain a lot of moisture 5 Feeding requirements With a cone crusher, the material can be fed directly into the machine until it's full and no silos and feeders are Jaw Crusher VS Cone Crusher (A Comparison From 7 Points)Iron ore minerals, particularly hematite and goethite, are beneficiated by a combination of size fraction, preconcentration, and flotation in stages (Fig 1345)Iron ore requires removal of silicate impurities of a finer size by flotation for highergrade products of +60% Fe ROM ore at 400–600 mm is fed to a primary crusher with product set at –40 mmIron Ore an overview ScienceDirect Topics

Feeding Material Identification for a Crusher Based on Deep

2022年3月19日 In large coal preparation plants with a capacity of 30 million tons/year, the belt speed can reach 7 m/s and the thickness of the material layer can reach 500 mm Therefore, in highthroughput and complex environments, the problem exists that harmful feeding materials such as iron and gangue are not easily detected, and thus fault 2014年11月15日 The present work explores the use of technique for order performance by similarity to ideal solution (TOPSIS) with fuzzy set theory to select best primary crusher for Golegohar Iron Mine in Iran Fuzzy TOPSIS method to primary crusher selection for Golegohar Iron 2023年10月30日 To address this, a stateoftheart crusher plant was introduced to revolutionize the iron ore extraction process Equipment and Their Performance: Primary Crusher: The jaw crusher is at the core crusher plant iron ore in indonesia LinkedIn

secondary crushing Mining Quarry Plant

2013年3月12日 Three in One Mobile Crusher limestone mobile crushing plant used in Qatar South Africa 30 tph limestone grinding plant Limestone grinding line in Kazan Russia South Africa 200 tph granite crushing line Philippines 150TPH Riverstone Crushing Plant Indonesia 180 tph Iron Ore crushing plant How Much VSI Sand Crusher2017年3月4日 The double jaw crusher is designed for crushing hard materials, also quarried materials, sand and gravel, and recycling [4, 5] crusher [4] The tie rod and compression spring ensure that the (PDF) SIZE REDUCTION BY CRUSHING METHODSSuperior™ MKIII primary gyratory crushers have new sets of shells and concaves, which have been implemented after countless hours of research and development The improvements to the Superior™ MKIII crushers brings up to 70% reduction in downtime Crusher maintenance downtime has also produced a significant size decrease Superior™ MKIII Series primary gyratory crushers

Crusher an overview ScienceDirect Topics

The primary crusher converts the feed size to one that is acceptable to the secondary crusher granite, basalt, river gravel, bauxite, marble, slag, hard rock, limestone, iron ore, magazine ore, etc, within a pressure resistance strength of 200 MPa Jaw crushers are characterized for different features such as a simple structure, easy McLanahan Mineral Sizers are designed to process a variety of materials, including copper, iron ore, gold, nickel, lithium/spodumene, coal, potash, phosphate and other hard rock and soft, noncoal minerals They can be McLanahan Mineral Sizers2021年3月25日 Hammermills can be used as a primary crusher in many types of aggregate and industrial applications, including limestone, marble, shale, gypsum, phosphate, bauxite, aluminum dross, uranium, cryolite, What Type of Crusher Is Best for Primary

Simulation and optimization of gyratory crusher

2020年10月1日 1 Introduction The gyratory crusher is widely used in primary crushing of metal ore such as iron ore and copper ore due to its high productivity and large feed inlet [[1], [2], [3]]In recent years, with the growth of the world's population, the development of urbanization and the improvement of living standards, the demand for the ore continues 2015年12月23日 Primary Crusher Selection Design , degradability and it being prone to dusting or not The crusher capacities given by manufacturers are typically in tons of 2,000 lbs and are based on crushing limestone weighing loose about 2,700 lbs per yard3 and having a specific gravity of 26 Wet, sticky and extremely hard or tough feeds will tend to Primary Crusher Selection Design 911 Metallurgist2019年8月8日 The iron ore crusher price; Different iron ore has different features According to these features, the crushers are made of different materials Primary crushing; The jaw crusher is generally used in the crushing process of iron ore The jaw crusher is a traditional and reliable coarse crushing equipment, and its application range Challenges and opportunities in the iron ore crusher market

Developments in iron ore comminution and classification

2015年1月1日 This chapter reviews current iron ore comminution and classification technologies and presents some examples of flowsheets from existing operations New trends and advances in comminution technologies are presented and discussed, particularly with regard to the impact on energy, operating, and capital costs Gyratory crusher: 2020年12月17日 Jaw crushers can be divided into two basic types, single and double toggle In the single toggle jaw crusher, an eccentric shaft is on the top of the crusher Shaft rotation, along with the toggle plate, causes a compressive action A double toggle crusher has two shafts and two toggle plates The first shaft is a pivoting shaft on the top of Crushing 101 – Different types of crushers for distinctive needs2011年7月27日 Ore processing The lump ore and sinter fine products extracted from the Brockman 4 are transported to the processing plant through 16 Komatsu 830EAC and two Komatsu 730E haul trucks The plant boasts a primary jar crusher, two secondary cone crushers, a six bin screening building and gravity separation system Processing can be Rio Tinto Brockman 4 Iron Ore Mine, Pilbara Mining

(PDF) Processing of Magnetite Iron Ores–Comparing

2009年1月1日 Also, equipment like ball mill is used at the final stages of grinding Among the comminution and grinding equipment, HPGR is increasingly utilized as tertiary crusher or primary mill because of