عنا

مرحبا هل يمكنني مساعدتك؟

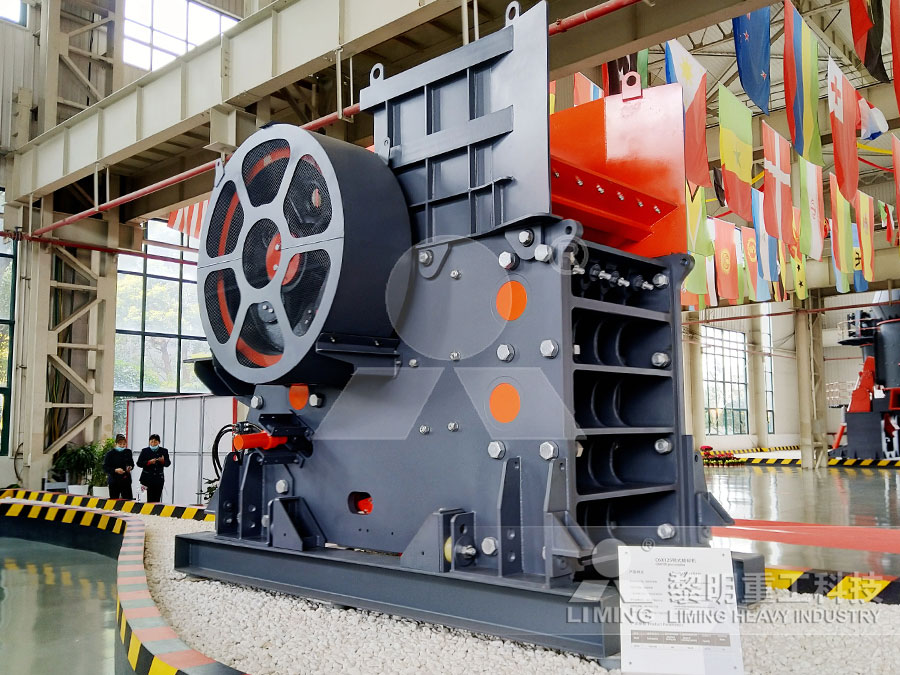

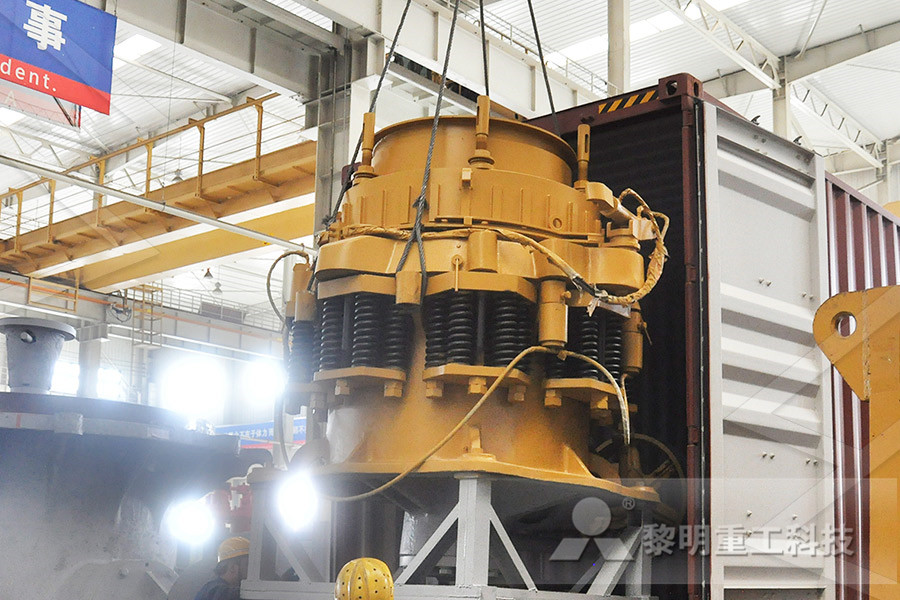

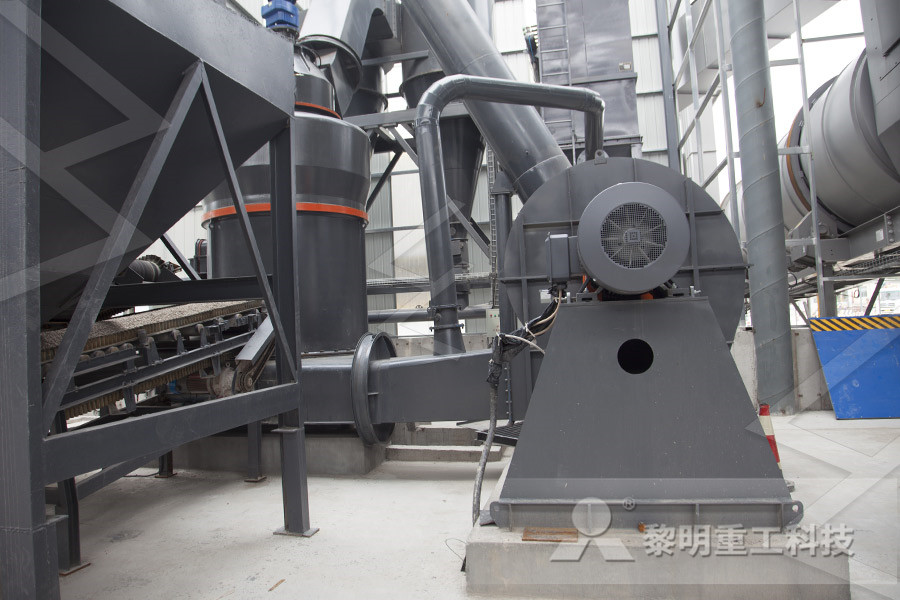

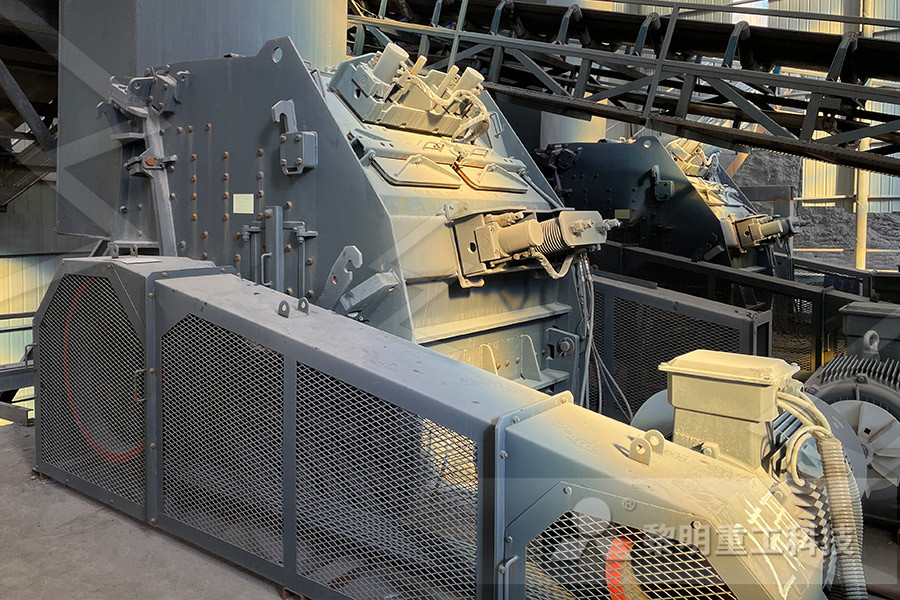

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

Better Quality Iron Ore Grinding Mill

2020-06-26T02:06:37+00:00

Iron ore grinding mill Grinding plants for Iron Ore

1, Raymond Mill, HC series pendulum grinding mill: low investment costs, high capacity, low energy consumption, equipment stability, low noise; is the ideal equipment for wollastonite powder processing But the degree of largescale is relatively lower compared to vertical 2023年11月3日 8 Victoria Cast Iron Manual Grain Mill If you are planning to grind wheat berries, you will need a grain mill that is especially Best Grain Mills In 2023 Top 10 Ultimate Reviews 2020年5月28日 The iron ore blend takes RT of 13 min when grounded in the BBM for 250% circulating load with 80% passing particle size of 56 Investigation on Iron Ore Grinding based on

Iron ore pelletization ScienceDirect

2015年1月1日 Iron ore lump, sinter, and pellets comprise the main burden of modern blast furnaces However, sinter and pellets are now the dominant blast furnace burden, 2015年3月15日 One reason is the dry inbed grinding principle Results of extensive test works with two types of magnetite iron ores in a Loesche VRM are presented here Research of iron ore grinding in a verticalrollermill2015年3月15日 The application of verticalrollermills (VRM’s) for ore grinding is part of the second strategy The grinding parts of a Loesche mill ( Fig 1) are a rotating table (1) with Research of iron ore grinding in a verticalrollermill

Buy Ore Ball Mill for Mineral Processing Iron

Types of ore ball mill with large crushing ratio and strong sealing for sale We have gold ore ball mill and iron ore ball mill for ore processing Click for free material testing2019年6月18日 Fitting the population balance model of batch grinding to data from a 254 cm mill in size reduction of an iron ore from Brazil resulted in unusual breakage response, that is, nonnormalizable breakage Optimization of Solids Concentration in Iron Ore 2021年6月23日 The grinding product particle size is the most crucial operational index of mineral grinding processes The size and consistency of the product directly affects the subsequent dressing and sintering In this OptimalSetting for Ore and Water Feeding in

Minerals Free FullText Research on Grinding

2022年10月26日 The particle size composition of grinding products will significantly affect the technical and economic indexes of subsequent separation operations The polymetallic complex ores from Tongkeng 2015年1月1日 The pelletization process is the primary consumer of binders in the iron ore industry The selection of an appropriate binder type and dosage is of critical importance in producing good quality pellets at a reasonable price Binders accomplish two very important functions in iron ore pelletization: Iron ore pelletization ScienceDirectIron ore is the key raw material for steel production enterprises Generally, iron ore with a grade of less than 50% needs to be processed before smelting and utilization After crushing, grinding, magnetic separation, Iron Ore Processing,Crushing,Grinding Plant

Buy Ore Ball Mill for Mineral Processing Iron Gold Ore Ball Mill

Ore Ball Mill Output size: 0074089mm Motor power: 185480kw Specification (mm): Φ750×750Φ2700×4500 Applications: It is used for processing various grindable mineral materials, nonferrous metal mineral processing, new building materials, etc : info@ballmillssupplier Get Price Now2020年3月28日 212 Ore Blend Grinding at HPGR and Ball Mill The ore blend was ground in a pilotscale HPGR (1 m diameter × 032 m width) at a maximum feed rate of 50 t/h The ground product was recirculated to the HPGR feeding hopper five or seven times, wherein every recirculation steps a sample was gathered for moisture and size distribution Development of a Novel Grinding Process to Iron Ore2016年10月20日 Grinding Balls Steel balls ranging from ¾ to 5 in in diameter are used Rods range from 1½ to 4 in in diameter and should be 3 to 4 in shorter than the inside mill length Tube mills are usually fed balls smaller than 2 in, whereas 4 or 5in balls are more commonly used for ballmill grindingGrinding Balls Rods 911 Metallurgist

High Pressure Grinding Rolls for Minerals AusIMM

2021年6月24日 duty In the iron ore industry, most of the machines are found in pellet feed applications However, there are a few notable examples where HPGRs are used for coarse iron ore grinding – in Chile, Mauritania and the USA The first large scale attempt at applying HPGRs to harder and more abrasive copper and gold ores was in 1996 at Sierrita2022年1月1日 Most of the highgrade hematite iron ores are typically subjected to simple dry processes of crushing and classification to meet the size specifications required for direct shipping ore (DSO) This involves multistages of crushing and screening to obtain lump (−315 + 63 mm) and fines (approximately −63 mm) minution and classification technologies of iron ore2023年10月27日 Grinding steel balls are the grinding media and the core components of a ball mill They can directly affect the grinding efficiency of the whole ore processing plant and the final product quality During the grinding process, grinding steel balls are used for mixing and milling materials (such as minerals, paints, and chemicals) into fine powdersChoose the Best Grinding Steel Balls for Your Ball Mill Fote

Optimization of Solids Concentration in Iron Ore Ball Milling

2019年6月18日 Important advances have been made in the last 60 years or so in the modeling of ball mills using mathematical formulas and models One approach that has gained popularity is the population balance model, in particular, when coupled to the specific breakage rate function The paper demonstrates the application of this methodology to 2020年2月26日 The present investigation involves the identify the physical properties of three different types of iron ores by using Bond ball mill The result shows that the maximum Bond work index of 14 KWh Investigation of iron ores based on the bond grindability test2015年3月15日 Verticalrollermills (VRM) are an energyefficient alternative to conventional grinding technology One reason is the dry inbed grinding principle Results of extensive test works with two types of magnetite iron ores in a Loesche VRM are presented here Within these test works, mill parameters like grinding pressure, separator speed Research of iron ore grinding in a verticalrollermill

Metals Free FullText Beneficiation of Low

2023年2月1日 This research is aimed at the upgradation of indigenous Pakistani iron ore, ie, Dilband iron ore (hematite), by utilizing common metallurgical processes First, the magnetic properties of the ore were 2022年1月1日 The pelletization process is the primary consumer of binders in the iron ore industry The selection of an appropriate binder type and dosage is of critical importance in producing good quality pellets at a reasonable price Binders accomplish two very important functions in iron ore pelletization: •Iron ore pelletization ScienceDirectJoyal good quality ball mill for iron ore grinding/ Gold Mining Machine $1,00000 Min Order: 1 set 10 yrs CN Supplier 00 /5 0 reviews Contact Supplier Chat now Factory Price Stone Grinding Machine, Mineral Dolomite Iron Ore Powder Grinding Mill Machine, Quartz Raymond Mill Machine $23,20000 there's no better place to Iron Ore Grinding Machine

Process Mineralogical Assessment of the Grinding Products

2022年1月12日 The grinding setup refers to the socalled Malmberget method used at LKAB, characterized by a subsequent circuit of rod and ball mill grinding The highest P 80 values were obtained by grinding only in the rod mill for 10 min (step A) Ball mill grinding for 25 min (step B) and 35 min (step C) gave a very narrow range of P 80 values2023年4月23日 grinding media in a grinding mill with about 2630 wt% chrome by Chen et al [37] using a phosphate ore in a modified ball laboratory ball mill whose electrochemical potential could be controlled(PDF) Grinding Media in Ball MillsA Review ResearchGate2013年8月1日 Likewise, Hebbar (2011) has studied the grinding wear behaviour of austempered ductile iron as media material in the comminution of Kudremukh haematite iron ore in a ball mill The grinding experiments were conducted under different pH conditions, ie pH = 70 and pH = 85, while keeping other parameters fixed, at a mill speed of 74 Consumption of steel grinding media in mills – A review

(PDF) EcoEfficient and CostEffective Process Design for

2013年9月16日 Reducing Grinding Energy and Cost Magnetite Iron Ore Design Case Study Efficiency of the comminution operations is traditionally assessed based on operating cost and energy consumption 2015年12月31日 Arrium Australia 0810 0810 0440 440 Iron Ore The pelletizing process involves the preparation of ra w materials; the proportioning and mixing of raw materials; the formation, preheating, and (PDF) Iron ore pelletization ResearchGate2020年2月5日 The mood was apprehensive as data scientists, metallurgists, and engineers from FreeportMcMoRan filed into the control room of a copperore concentrating mill in Bagdad, Arizona, on the Inside a mining company’s AI transformation

Grinding Mills 911 Metallurgist

1 天前 Grinding mill shells up to 26 feet in length are rolled from structural steel plate having approximately 55,000 psi tensile strength Shells longer than 26 feet are rolled from carbonsilicon flange quality steel plate 2017年11月1日 Introduction An iron ore mill relies on the grinding and impact of grinding balls to complete iron ore crushing The operating process of an iron ore mill is as follows: first, the ores are poured into the mill, and both the ores and the grinding balls are lifted by the lifting bar arranged on the wall of the cylinder body to a certain height, after which Friction and wear of liner and grinding ball in iron ore ball mill This study focussed on flowsheet simulation for mineralogicalbased approach to geometallurgy of iron ores Process unit models used were selected based on their applicability at particle level for iron ore beneficiation and flowsheet simulation The feed streams for plant simulation were runofmine feed and forecast feed from ore textural Process simulations in mineralogybased geometallurgy of iron

Iron Ore Pelletization Technology and its Environmental

2015年1月1日 Higher quality means fewer fines, better reducibility and less variation in compression 588 GP Singh et al / Procedia Earth and Planetary Science 11 ( 2015 ) 582 – 597 strength x Continuous Improvements There are ongoing developments in the GrateKiln System that has significantly improved the reliability and ease maintenance of 2015年3月15日 The application of verticalrollermills (VRM’s) for ore grinding is part of the second strategy The grinding parts of a Loesche mill ( Fig 1) are a rotating table (1) with a horizontal grinding track and rollers (2), which are pressed onto the table by lever arms and a hydro pneumatic spring systemResearch of iron ore grinding in a verticalrollermill2020年1月3日 22 Grinding Studies Two kinds of mills, BBM and LBM, were used to achieve the desired P 80 passing percentage of 150 μm with an acceptable range of hematite liberation (> 75%) at optimum grinding time The BBM is a standard ball mill having a length and diameter of 300 mm × 300 mm with smooth liner as shown in Fig 2A Estimation of Grinding Time for Desired Particle Size

Rethinking the value of mill relining Mining Magazine

2016年11月3日 Then, in the late 1980s when the price of copper rose quickly from a low of $062/lb to a high of $162/lb, this substantial increase in price further fuelled the industry demand for larger diameter SAG mills, with mill power quickly doubling from 15,000hp to 30,000hp (11,00022,000kW) As SAG mills grew in size and number, so did the size and 2021年3月15日 In spite of the important advances in modelling and simulation of autogenous and semiautogenous grinding made in recent decades (NapierMunn et al, 1996, Morrell, 2004), risks exist in designing a circuit adopting AG/SAG mills for lowgrade itabirite iron ores from benchscale paring strategies for grinding itabirite iron ores in 2021年2月16日 Iron ore grinding, Australia 7 The Genuine Article The Enduron® HPGR tyre an innovative and different design which provides: • Improved wear life: up to 20% better than available alternatives • Guaranteed performance • Highest quality studs: no recycled material • L ateral stud design is optimised for impact load: uniqueEnduron HPGR High Pressure Grinding Roll First choice

Ball Mill Ball Mills Wet Dry Grinding DOVE

2 天之前 DOVE small Ball Mills designed for laboratories ball milling process are supplied in 4 models, capacity range of (200g/h1000 g/h) For small to large scale operations, DOVE Ball Mills are supplied in 17 2018年9月1日 After comminution and dry grinding of the eudialyte ore by a vertical roller mill, an eudialyte concentrate was recovered using WHIMS with a magnetic field intensity of 112 T The nonmagnetic Study on the Characterisation and Processing of 2021年9月5日 Based on the grinding rate constant K, it is confirmed that the grinding rate is dependent upon the particle size and the amount of material fed in the mill Figure 4 , which provides a better illustration of the results, confirms that the grinding efficiency increases as the particle size increases and when the material filling volume in the Modeling of Bauxite Ore Wet Milling for the Improvement of

Minerals Free FullText Analysis and Optimization of Grinding

2022年1月23日 This work concentrates on the energy consumption and grinding energy efficiency of a laboratory vertical roller mill (VRM) under various operating parameters For design of experiments (DOE), the response surface method (RSM) was employed with the VRM experiments to systematically investigate the influence of operating parameters on 2023年10月12日 To date, CITIC HIC has cumulatively produced and delivered over 1,550 mineral grinding mills, with a total installed power of 3,900MW Our largesize grinding mills hold a market share of 85% in the domestic mining market, and have been exported to more than 50 countries and regions This means that we are a world's leading manufacturer Grinding Mills Mineral Processing Equipment CITIC HICA ball mill is a form of grinder that is used to blend or grind materials for use It is a cylindrical device mainly for grinding material such as iron ores, ceramic raw materials, glass, steel, etc The ball mill works on impact and attrition principle Its impact is the size reduction given that the balls drop from almost the top of the shellBall Mill Grinding Media Options Orbis Machinery

(PDF) A Method of Ore Blending Based on the Quality of

2021年5月31日 Raw ore conditions include OG (Ore Grade), HQC (HighQuality Content), LQC (Low Quality Content), MPV (Minimum Production V olume), and GR (Geological Reserves) Ore grade refers to the ratio of 2015年6月3日 • Produce a concentrate from the mined ore to reduce downstream transport costs • Produce a final product for shipping to the customer Crushing Grinding Sizing Separation Concentration Disposal Reduce size to allow liberation of the material (Comminution) Separate wanted and unwanted material Concentrate wanted material pwcau Productivity and Cost Management2015年12月10日 Measure Variability Develop to use a simple powerbased model like the Bond Work Index Measures the time in minutes required to grind a 2 kg sample from 80% minus inch (127 mm) to 80% minus 10 Mesh (17mm) in the 12 x 4 SPI Test Mill Link to ore hardness determines power for AG or SAG milling which wasIron Ore Metallurgical Testwork PDF PDF Iron Ore Mill (Grinding)

Minerals Free FullText Research on Grinding

2022年10月26日 The particle size composition of grinding products will significantly affect the technical and economic indexes of subsequent separation operations The polymetallic complex ores from Tongkeng 2015年1月1日 The pelletization process is the primary consumer of binders in the iron ore industry The selection of an appropriate binder type and dosage is of critical importance in producing good quality pellets at a reasonable price Binders accomplish two very important functions in iron ore pelletization: Iron ore pelletization ScienceDirectIron ore is the key raw material for steel production enterprises Generally, iron ore with a grade of less than 50% needs to be processed before smelting and utilization After crushing, grinding, magnetic separation, Iron Ore Processing,Crushing,Grinding Plant

Buy Ore Ball Mill for Mineral Processing Iron Gold Ore Ball Mill

Ore Ball Mill Output size: 0074089mm Motor power: 185480kw Specification (mm): Φ750×750Φ2700×4500 Applications: It is used for processing various grindable mineral materials, nonferrous metal mineral processing, new building materials, etc : info@ballmillssupplier Get Price Now2020年3月28日 212 Ore Blend Grinding at HPGR and Ball Mill The ore blend was ground in a pilotscale HPGR (1 m diameter × 032 m width) at a maximum feed rate of 50 t/h The ground product was recirculated to the HPGR feeding hopper five or seven times, wherein every recirculation steps a sample was gathered for moisture and size distribution Development of a Novel Grinding Process to Iron Ore2016年10月20日 Grinding Balls Steel balls ranging from ¾ to 5 in in diameter are used Rods range from 1½ to 4 in in diameter and should be 3 to 4 in shorter than the inside mill length Tube mills are usually fed balls smaller than 2 in, whereas 4 or 5in balls are more commonly used for ballmill grindingGrinding Balls Rods 911 Metallurgist

High Pressure Grinding Rolls for Minerals AusIMM

2021年6月24日 duty In the iron ore industry, most of the machines are found in pellet feed applications However, there are a few notable examples where HPGRs are used for coarse iron ore grinding – in Chile, Mauritania and the USA The first large scale attempt at applying HPGRs to harder and more abrasive copper and gold ores was in 1996 at Sierrita2022年1月1日 Most of the highgrade hematite iron ores are typically subjected to simple dry processes of crushing and classification to meet the size specifications required for direct shipping ore (DSO) This involves multistages of crushing and screening to obtain lump (−315 + 63 mm) and fines (approximately −63 mm) minution and classification technologies of iron ore2023年10月27日 Grinding steel balls are the grinding media and the core components of a ball mill They can directly affect the grinding efficiency of the whole ore processing plant and the final product quality During the grinding process, grinding steel balls are used for mixing and milling materials (such as minerals, paints, and chemicals) into fine powdersChoose the Best Grinding Steel Balls for Your Ball Mill Fote

Optimization of Solids Concentration in Iron Ore Ball Milling

2019年6月18日 Important advances have been made in the last 60 years or so in the modeling of ball mills using mathematical formulas and models One approach that has gained popularity is the population balance model, in particular, when coupled to the specific breakage rate function The paper demonstrates the application of this methodology to