عنا

مرحبا هل يمكنني مساعدتك؟

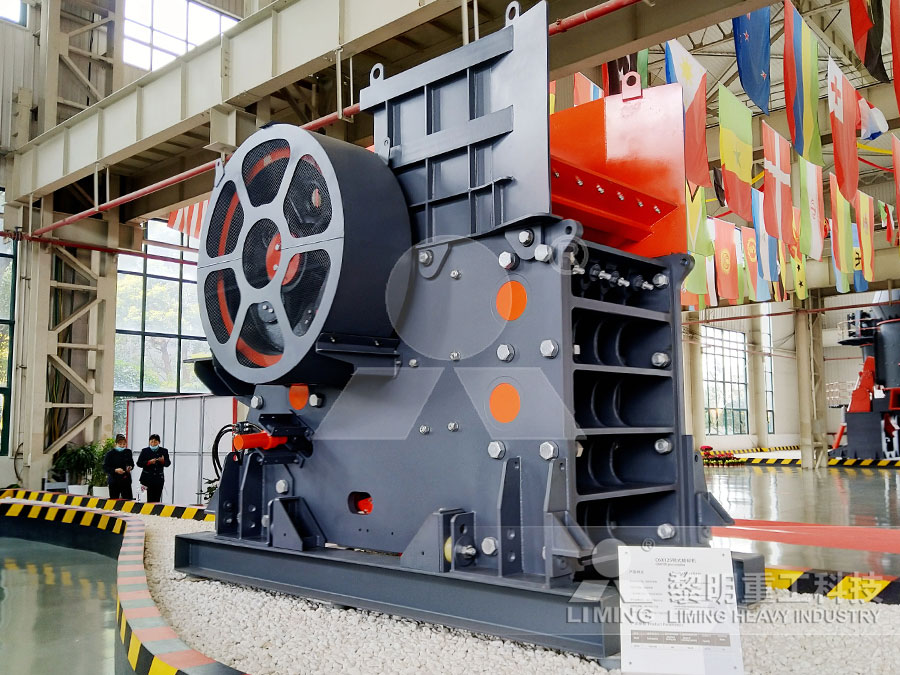

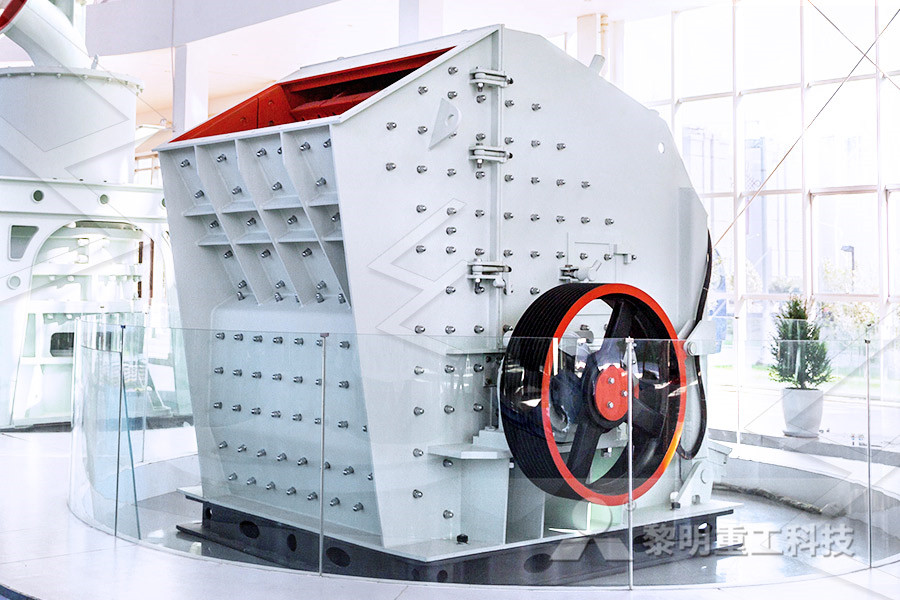

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

definition of coal crusher

2020-08-28T20:08:21+00:00

What is coal crusher? Studybuff

2019年6月25日 What is coal crusher? By Perrine Juillion / June 25, 2019 Primary coal crusher: Used for larger coal size The primary coal crushers may be of different types BHARATH Mild Steel 2 to 100 TPH Coal Crushers, Model Number: Bcoc, Upto 150 Hp ₹ 3,90,000/ Piece Get Latest Price Type of Crushing Machines: Block Crushing Machine Capacity: 2 to 100 TPH Brand: Coal Crusher Coal Crushing Machine Latest Price, 2023年10月8日 1 Jaw crusher The jaw crushers are popular primary crushers for coal They are often used in mines and quarries where large amounts of coal are mined The 6 Types of Coal Crusher: Which Is Best for Crushing My Coal?

coal crusher English definition, grammar, pronunciation,

Learn the definition of 'coal crusher' Check out the pronunciation, synonyms and grammar Browse the use examples 'coal crusher' in the great English corpusThe breaking head gyrates inside an inverted truncated cone These crushers are designed so that the head to depth ratio is larger than the standard gyratory crusher and the cone Crusher an overview ScienceDirect TopicsCoal Mill, Coal Crusher Coal crusher definition Coal crusher is a type crusher of ore crushing Primary coal crusher: Coal jaw crusher, coal impact crusher, coal hammer Crusher And Mills Definition Crusher Mills, Cone Crusher,

Definition Of Stone Crusher Crusher Mills, Cone Crusher,

Crusher definition of Crusher in the Free Online Encyclopedia crusher, machine used to reduce materials such as ore, coal, stone, and slag to particle sizes that are convenient Pulverizer Meaning and Example Sentence: Meaning, definition A pulverizer is a mechanical device for the grinding of many different types of materials For example, What Is Meaning Of Coal Pulverizer Crusher Mills, Cone CrusherPrimary coal crusher: Used for larger coal size The primary coal crushers may be of different types such as: (1) coal jaw, (2) coal hammer, and (3) ring granulator Secondary coal crusher: Used when the coal coming from the supplier is large enough to be handled by a single crusher The primary crusher converts the feed size to one that is Crusher an overview ScienceDirect Topics

Roll Crusher an overview ScienceDirect Topics

Jaw Crusher This type of primary crusher is usually used for crushing shale to reduce it to a size suitable for handling Roll Crusher For a given reduction ratio, singleroll crushers are capable of reducing ROM material to a product with a top size in the range of 200–18 mm in a single pass, depending upon the top size of the feed coal 2019年12月10日 Blake crusherthe swing jaw is fixed at the upper position Dodge crusherthe swing jaw is fixed at the lower position Universal crusherthe swing jaw is fixed at an intermediate position The type of Type of crushers and their difference JXSC Mining2017年3月4日 The double jaw crusher is designed for crushing hard materials, also quarried materials, sand and gravel, and recycling [4, 5] crusher [4] The tie rod and compression spring ensure that the (PDF) SIZE REDUCTION BY CRUSHING METHODS

Gyratory Crusher (Gyratory Crushers Explained) saVRee

A primary crusher is designed to receive runonmine (ROM) rocks directly from the mines Gyratory crushers typically crush to reduce the size of aggregate to a maximum of about onetenth of its original size Gyratory crushers are always installed vertically orientated A gyratory crusher’s size is classified by:2015年12月26日 The Crusher throw is defined as the distance in the direction of compression the moving crushing surfaces/plates travel from OSS to CSS Throw = OSS – CSS OSS and CSS will define a crusher’s performance The throw of the crusher is the distance that moving jaw moves in going from OSS to CSS The capacity is a function of Crushing in Mineral Processing 911 Metallurgist2015年7月25日 The screening a Static Grizzly separator does is sort and classify the rock according to size The first stage is SCALPING This is the practice of removing any material that may slow production It may be rock that is too big for the equipment to effectively handle, or fine material that is taking up valuable space and will consume precious Static Grizzly Screen as a Rock Separator 911 Metallurgist

Coal Handling System Coal Handling Plant In Thermal Power

2023年11月2日 Ring granulator type crusher is generally used in coal handling plant to crush the coal Stacking Reclaiming Process; In stacking process crushed coal are stored in a yard This process is generally used when boiler bunker level is full In reclaiming process the stored coal are reclaimed for sending to boiler bunkers2018年1月4日 A Abutment In coal mining, (1) the weight of the rocks above a narrow roadway is transferred to the solid coal along the sides, which act as abutments of the arch of strata spanning the roadway; and (2) the weight of the rocks over a longwall face is transferred to the front abutment, that is, the solid coal ahead of the face and the back Glossary of Mining Terms Coal Education2020年6月3日 Cone crushers are compression machines that take in raw materials and reduce them in size by crushing them A variety of industries rely on these tools, such as the concrete, aggregate, mining, coal, and natural gas industries Inside the crusher, a piece of steel, known as the mantle, rotates eccentricallyA Detailed Overview of Cone Crushers and What You Need

Crushing of coal and calculation of size reduction

2015年2月24日 Crushing efficiency has been defined in the literature from the power consumption point of view But while operating a process plant, it is more important that the crushing efficiency is defined in terms of the The three types of crushers most commonly used for crushing CDW materials are the jaw crusher, the impact crusher and the gyratory crusher (Figure 44)A jaw crusher consists of two plates, with one oscillating back and forth against the other at a fixed angle (Figure 44(a)) and it is the most widely used in primary crushing stages (Behera et al, 2014)Impact Crusher an overview ScienceDirect TopicsMcLanahan FeederBreakers come in a variety of configurations and designs for use underground and above They are particularly useful in underground and open pit mining of coal, lignite, salt, gypsum and other McLanahan FeederBreakers

Crusher an overview ScienceDirect Topics

The roll crusher consists of a pair of horizontal cylindrical manganese steel spring rolls Srikanth [7] used a jaw crusher to create −37 μm coal dust particles Coal samples were obtained from coal mines in addition to some samples from the same source as Thakur's samples They used a Microtrac Standard Range Analyzer (SRA) and Small 2017年6月30日 A review on the design and operations challenges of a single toggle jaw crusher is presented Strength and fracture toughness of the material to be crushed are intrinsic properties that determine (PDF) DESIGN AND OPERATIONS CHALLENGES OF A SINGLE TOGGLE JAW CRUSHER Contact us today to discuss your application in detail with one of our experienced sales engineers Call (314) 4335464, us at info@williamscrusher, or near you Williams Patent Crusher has become the industry leader in coalcrushing and pulverizing equipment Learn more about our productsCoal Crushers Coal Pulverizers Mills Williams Crusher

How it Works: Crushers, Grinding Mills and Pulverizers

2017年6月2日 Crushers, grinding mills and pulverizers are types of grinding equipment used to transform or reduce a coarse material such as stone, coal, or slag into a smaller, finer material Grinding equipment can be classified into to two basic types, crushers and grinders Industrial crushers are the first level of size reducer; further granularization Gyratory crushers are principally used in surfacecrushing plants The gyratory crusher (Figure 65) consists essentially of a long spindle, carrying a hard steel conical grinding element, the head, seated in an eccentric sleeveThe spindle is suspended from a “spider” and, as it rotates, normally between 85 and 150 rpm, it sweeps out a conical path within Crushing Chamber an overview ScienceDirect Topics2015年4月3日 Types of crushers Crushers are classified into three types based upon the stage of crushing they accomplish These are (i) primary crusher, (ii) secondary crusher, and (iii) tertiary crusher The primary crusher receives material directly from run of mine (ROM) after blasting and produces the first reduction in sizeCrushers and Their Types – IspatGuru

(PDF) Cone Crusher Performance ResearchGate

2015年5月13日 geometry, crusher dynamics and rock material characteristics Concave, mantle, eccentricity and location of the pivot point together form the chamber resulting motion of the mantle and main shaft 2021年4月12日 The rock breaks and falls out the bottom These types of crushers are usually applied as tertiary or quaternary crushers with less than 2” (75 mm) feed or smaller Some Vertical Shaft Impactors can be used Downstream Crushing Options for Secondary, 2023年10月19日 Coal is a black or brownishblack sedimentary rock that can be burned for fuel and used to generate electricity It is composed mostly of carbon and hydrocarbons, which contain energy that can be Coal National Geographic Society

OPERATION AND MAINTENANCE OF CRUSHER HOUSE

2015年4月10日 449 Int J Mech Eng Rob Res 2013 Girja Lodhi, 2013 OPERATION AND MAINTENANCE OF CRUSHER HOUSE FOR COAL HANDLING IN THERMAL POWER PLANT Girja Lodhi1* *Corresponding Author: Girja Lodhi, girjalodhi@yahoo Many utility systems in the world have power plants operating with fossil fuelThe purpose of the primary crusher is to reduce the ROM ore to a size amenable for feeding the secondary crusher or the SAG mill grinding circuit The ratio of reduction through a primary crusher can be up to about 8:1 Feed: ROM up to 15 m Product: 300mm (for transport) to 200mm (for SAG mill) Feed Rate:AMIT 135: Lesson 5 Crushing – Mining Mill Operator Training2020年2月6日 What is the productive work time of the unit crusher? What is the productivity of the crusher unit? 2 Literature Review 21 Definition of Coal Coal comes from plants that have died and are buried in a basin filled with water for a very long time, reaching millions of years In the process of coal formation, many factors influenceEvaluation of Crusher Productivity in Coal Processing

What is the functions of crusher LinkedIn

2023年2月7日 A crusher is a machine designed to reduce large solid objects into smaller pieces by applying force, typically through compression or impact The main functions of a crusher include: 1Reduction crusher coal definition dictionary – definition of crusher tender expressions iron ore mines india 100mm dia; definition of a coal crusher; car crusher video; capex mobile crusher unit; coal cage mill Crusher And Mills Definition Crusher Mills, Cone Crusher, Srikanth [7] used a jaw crusher to create −37 μm coal dust particles Coal samples were obtained from coal mines in addition to some samples from the same source as Thakur's samples They used a Microtrac Standard Range Analyzer (SRA) and Small Particle Analyser (SPA), which measured projected area (and hence diameter) using laser Jaw Crusher an overview ScienceDirect Topics

Crushing Plant Design and Layout Considerations 911

2016年2月24日 • Electronic control of crusher discharge opening and feed rate With adjustment of a crusher’s discharge opening, as the production continues through an online coarse size analysis of the crushed product (digital image analyses) Dance, A 2001) • More attention is being paid to the impact on crushing circuit design caused by variations2020年9月1日 Gyrfalcon 我相信很多同学在学习Aspen的时候,一定会参考官方的教程。 其中的第二章,煤炭的热解气化肯定会给很多新人带来心理阴影,因为热解气化会各种报错,这篇笔记就重点讲解下热解这块。 热解 Aspen Plus 学习笔记(2):热解 知乎Contribute to naicha22/2022 development by creating an account on GitHub2022/ coal crushing definitionmd at main naicha22/2022

Introduction to Mineral Processing Sepro Labs

2021年11月22日 Seconday Crushers Cone Crusher The most common type of seconday crusher is the cone crusher A cone crusher is very similar to the gyratory but has a much shorter spindle with a larger diameter crushing surface relative to its the vertical dimension The eccentric motion of the inner crushing cone is similar to that of the gyratory crusher2022年2月15日 A machine with large, rotating tungsten carbide teeth Used in underground mines to scrape coal from coal beds These can sometimes be controlled remotely Conveyor A general term for equipment to move material from one point to another in a continuous fashion Types include belt conveyors and chain conveyors CrusherMining Equipment: AZ List for Maintenance Contractors2015年10月8日 Coal handling plant of thermal power station –A New Approach By Makarand Joshi (between Crusher No1and transfer house no2) These machines are denoted as M1, M2, M3, M4, M5, M6 Select the machine, which required maximum period This will define your shut down period Select other machine, which required Shut down management Plant Maintenance

Types of Crushers 911 Metallurgist

2015年6月23日 An example of the former is the Fairmount crusher, of the latter, the Edison roll crusher notably the light coal crushing type, have more of a tearing action, as contrasted to the heavy sledging performance of such machines as the Fairmount crusher Here are several, but not all, types of crushers: Double Toggle Jaw Crusher Single 1 天前 Ring granulator type crusher is generally used in coal handling plant to crush the coal Stacking Reclaiming Process; In stacking process crushed coal are stored in a yard This process is generally used when boiler bunker level is full In reclaiming process the stored coal are reclaimed for sending to boiler bunkersCoal Handling System Coal Handling Plant In Thermal Power The coal is first crushed into minute particles using equipment called pulverizes The main function of the Primary air fan or PA fan is to carry the pulverized coal to the furnace as fuel for combustion This process is used to create the steam that is the primary process in the thermal power plant In power plants, the PA fans supply air for Coal Based Fuel Feeding System for Boiler Inst Tools

McLanahan Jaw Crushers

The Jaw Crusher was first introduced by Eli Whitney Blake in 1858 as a doubletoggle Jaw Crusher Introduced in 1906, McLanahan’s Universal Jaw Crusher was one of the first modern era overhead eccentric Jaw Crushers On the overhead eccentric style Jaw Crusher, the moving swing jaw is suspended on the eccentric shaft with heavyduty double They can be used in coal, salt, coke, glass, and trona operations, among others Triple Roll Crushers combine a Single Roll Crusher with a Double Roll Crusher to form a crusher that is capable of achieving a 6:1 reduction ratio in the primary stage and a 4:1 reduction in the secondary stage while producing a cubicle product at high capacityMcLanahan Roll CrushersPrimary coal crusher: Used for larger coal size The primary coal crushers may be of different types such as: (1) coal jaw, (2) coal hammer, and (3) ring granulator Secondary coal crusher: Used when the coal coming from the supplier is large enough to be handled by a single crusher The primary crusher converts the feed size to one that is Crusher an overview ScienceDirect Topics

Roll Crusher an overview ScienceDirect Topics

Jaw Crusher This type of primary crusher is usually used for crushing shale to reduce it to a size suitable for handling Roll Crusher For a given reduction ratio, singleroll crushers are capable of reducing ROM material to a product with a top size in the range of 200–18 mm in a single pass, depending upon the top size of the feed coal 2019年12月10日 Blake crusherthe swing jaw is fixed at the upper position Dodge crusherthe swing jaw is fixed at the lower position Universal crusherthe swing jaw is fixed at an intermediate position The type of Type of crushers and their difference JXSC Mining2017年3月4日 The double jaw crusher is designed for crushing hard materials, also quarried materials, sand and gravel, and recycling [4, 5] crusher [4] The tie rod and compression spring ensure that the (PDF) SIZE REDUCTION BY CRUSHING METHODS

Gyratory Crusher (Gyratory Crushers Explained) saVRee

A primary crusher is designed to receive runonmine (ROM) rocks directly from the mines Gyratory crushers typically crush to reduce the size of aggregate to a maximum of about onetenth of its original size Gyratory crushers are always installed vertically orientated A gyratory crusher’s size is classified by:2015年12月26日 The Crusher throw is defined as the distance in the direction of compression the moving crushing surfaces/plates travel from OSS to CSS Throw = OSS – CSS OSS and CSS will define a crusher’s performance The throw of the crusher is the distance that moving jaw moves in going from OSS to CSS The capacity is a function of Crushing in Mineral Processing 911 Metallurgist2015年7月25日 The screening a Static Grizzly separator does is sort and classify the rock according to size The first stage is SCALPING This is the practice of removing any material that may slow production It may be rock that is too big for the equipment to effectively handle, or fine material that is taking up valuable space and will consume precious Static Grizzly Screen as a Rock Separator 911 Metallurgist

Coal Handling System Coal Handling Plant In Thermal Power

2023年11月2日 Ring granulator type crusher is generally used in coal handling plant to crush the coal Stacking Reclaiming Process; In stacking process crushed coal are stored in a yard This process is generally used when boiler bunker level is full In reclaiming process the stored coal are reclaimed for sending to boiler bunkers2018年1月4日 A Abutment In coal mining, (1) the weight of the rocks above a narrow roadway is transferred to the solid coal along the sides, which act as abutments of the arch of strata spanning the roadway; and (2) the weight of the rocks over a longwall face is transferred to the front abutment, that is, the solid coal ahead of the face and the back Glossary of Mining Terms Coal Education2020年6月3日 Cone crushers are compression machines that take in raw materials and reduce them in size by crushing them A variety of industries rely on these tools, such as the concrete, aggregate, mining, coal, and natural gas industries Inside the crusher, a piece of steel, known as the mantle, rotates eccentricallyA Detailed Overview of Cone Crushers and What You Need