عنا

مرحبا هل يمكنني مساعدتك؟

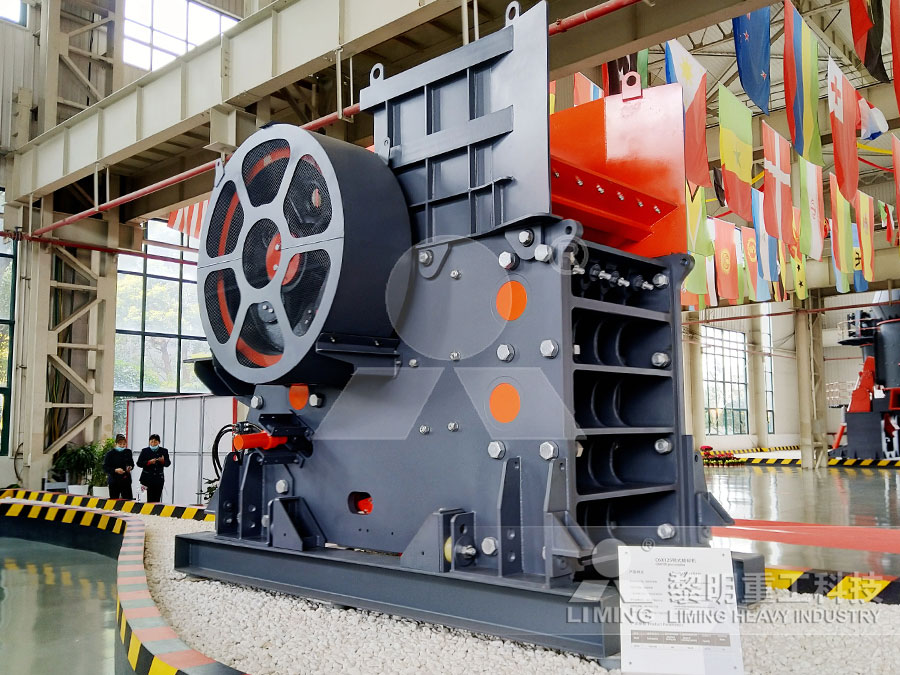

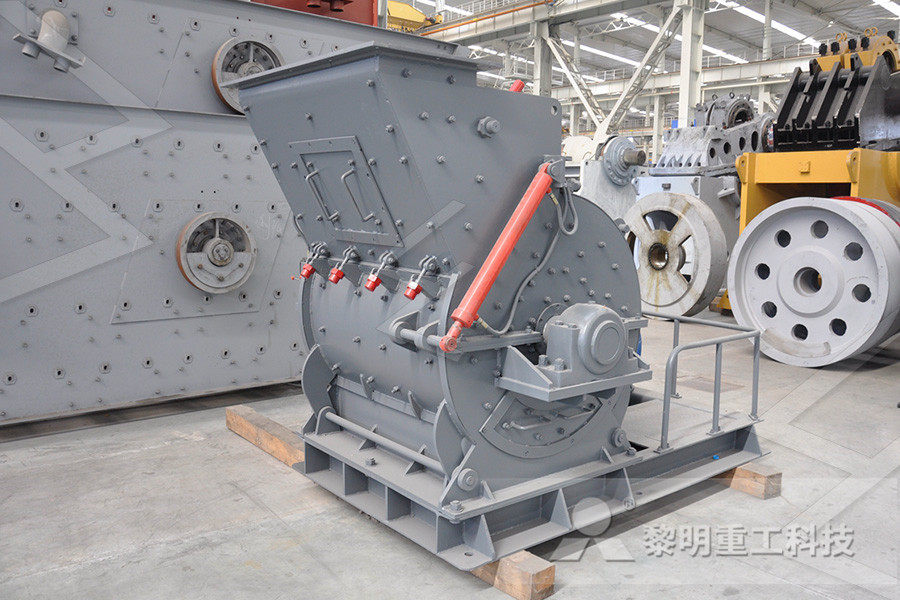

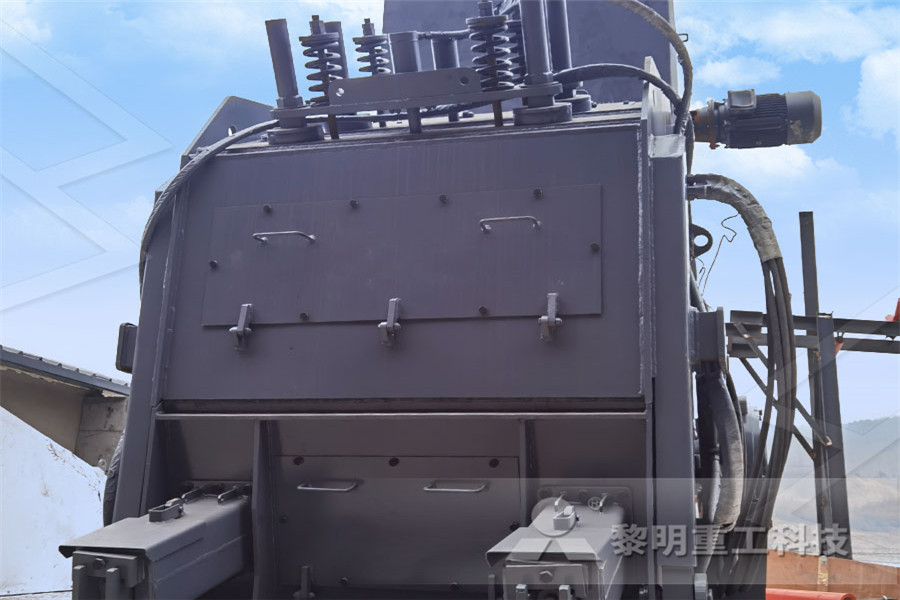

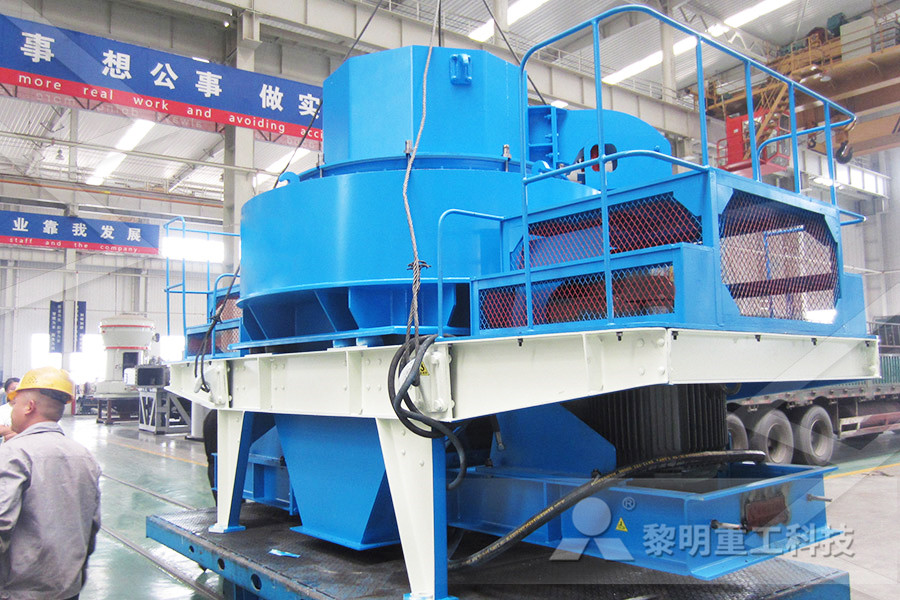

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

grinding mills for taconite ore

2020-12-09T22:12:25+00:00

Taconite Minnesota DNR

2023年11月3日 Taconite is a lowgrade iron ore When the highgrade natural iron ore was plentiful, taconite was considered a waste rock and not used But as the supply of high Jun 03, 2020 Traditional taconite pelletmaking processes use a rod mill to get the rock to the consistency of coarse sand, and a ball mill to grind the rock into a fine powder This 用于杆状石矿石的研磨厂 必威网址2015年9月1日 following taconite ore production processes will be covered by the proposed rule (EPA, 2001): C liberation of the iron ore by wet or dry crushing and grinding in Taconite Mining and Processing Industry Profile US EPA

Autogenous Grinding Iron Ore 911 Metallurgist

2018年6月23日 The autogenous grinding flowsheet represents the latest in taconite plant design and metallurgical technology The flowsheet consists of one stage of crushing and 2022年1月1日 When hard pebbles rather than steel balls are used as the grinding media, the mills are known as “pebble mills” As mentioned earlier, pebble mills are widely used Comminution and classification technologies of iron oreGrinding Mills For Taconite Ore srimaruthigranites 1123 taconite ore processing know more taconite is a hard banded lowgrade ore from the feed to the next cru Toggle navigation Grinding Mills For Tanite Ore paludpatrimoine

Taconite EROS USGS

2023年11月3日 Taconite is a hard, dense rock containing a mixture of silicates and magnetite and is abundant on the Mesabi Range New processing methods developed in 2022年4月1日 1 Introduction Artisanal and smallscale mining (ASM) contribute significantly to the economic development of several countries (The World Bank, 2008)It Production of gold mine tailings based concrete pavers by 2023年10月19日 3W is 35% more efficient than a lab scale ball mill for an iron ore An independent side by side study was performed on a 43 m x 69 m ball mill and VTM800WB Vertimill both using the same sizeVertimill as the definitive step before concentration

Inside the mines and megamachines of the Iron

2023年5月13日 They do this by tumbling the ore with 5inch steel balls and water inside a long cylinder that is 27 feet in diameter It takes 7,000horsepower motors to run these mills Eric Roper / Star Tribune2022年8月2日 The Planet Positive Vertimill ® grinding mills are expected to save more than 30% of the installed power compared to a conventional ball mill circuit “We are pleased that our customer has chosen the Outotec to deliver energyefficient 2019年4月8日 Vertical Agitated Media Mill modeling has become subject of a research project due to its potential application as a secondary grinding mill as well as regrind and pellet feed preparation projects(PDF) Vertimill as the definitive step before concentration

1123 Taconite Ore Processing US EPA

2015年9月10日 The taconite ore processing industry produces usable concentrations of ironbearing material by removing nonferrous rock (gangue) from lowgrade ore The sixdigit Source Classification Code (SCC) for taconite ore processing is 303023 Table 11231 lists the SCCs for taconite ore processing Taconite is a hard, banded, lowgrade ore, 1985年6月1日 Wet grinding in the presence of oxygen and pyrrhotite Grinding media wear for the three types of steel balls in the wet grinding of taconite and quartzite is illustrated in Table 3 The pH of the ore slurry in the grinding of taconite remained in the narrow range 81 84 in the presence and absence of pyrrhotiteCorrosive and abrasive wear in ore grinding ScienceDirect2015年9月10日 semiautogenous or autogenous grinding mills (using larger pieces of the ore to grind/mill the smaller pieces), then to pebble or ball mills Ideally, the liberated particles of iron minerals and barren gangue should be removed from the grinding circuits as soon as they are formed, with larger particles returned for further grinding1123 Taconite Ore Processing US EPA

Beneficiation of Iron Ore 911 Metallurgist

2016年5月24日 In place of initially grinding 85 to 90% minus 325, the grind if coarsened to 8085% minus 325mesh will result in greater initial tonnage treated per mill section Considerable advantage is to be gained by this approach FreeFlow “SubA” Flotation is a solution to the effective removal of silica from magnetic taconite concentrates2021年2月18日 semiautogenous or autogenous grinding mills (using larger pieces of the ore to grind/mill the smaller pieces), then to pebble or ball mills Ideally, the liberated particles of iron minerals and barren gangue should be removed from the grinding circuits as soon as they are formed, with larger particles returned for further grinding1123 Taconite Ore Processing US EPAA simplified flow diagram of these processing steps is shown in Figure 21 Table 22 provides a key to the SCCs for taconite ore processing, as indicated in Figure 21 Liberation is the first step in processing crude taconite ore AP42 Background Document for Section 1123 Taconite Ore Processing

Sealing solutions for challenging environments

2015年6月4日 The SKF Taconite Seal is a new global solution for split housings for selfaligning bearing applications in the mining, mineral and metal processing, cement, marine and pulp and paper industries where 2011年1月6日 reserves of taconite in the area around the Great Lakes In 1943, Dr Davis, a professor at the University of Minnesota, Mines Experiment Station, invented a method for processing taconite containing low grade iron ore His process involved grinding taconite to remove gangues and upgrading the iron ore (ie, an ore beneficiation process)KOBELCO Pelletizing Process2023年11月1日 The SKF Taconite Seal consists of two rings (one stationary and one rotating) which form a very narrow labyrinth between the two rings The rotating labyrinth ring carries a Vring seal that seals against the stationary labyrinth ring The Vring seal blocks contaminants from entering the bearing housing and aids the purging of SKF Taconite Seal SKF SKF

1123 Taconite Ore Processing US Environmental

2021年6月25日 The taconite ore processing industry produces usable concentrations of ironbearing material by removing nonferrous rock (gangue) from lowgrade ore The sixdigit Source Classification Code (SCC) for taconite ore processing is 303023 Table 11231 lists the SCCs for taconite ore processing Taconite is a hard, banded, lowgrade ore, 2022年8月1日 National Steel Pellet Company’s Secondary Grinding Circuit Modifications, by J E Wennen, W J Nordstrom, and D L Murr, in Comminution Practices, ed S K Kawatra, p1925, SME, 1995 Liberation for Magnetic Taconite Ore in Tumbling Mills and Its Implementation in a BASIC Computer Program, University of MinnesotaDuluth, COLERAINE MINERALS RESEARCH LABORATORY1987年2月2日 These liners were used in 82 m diameter SAG mills to grind taconite ore The mill revolved at 112 rev min 1 and the ball volume was 7% 8% of 251 TABLE 1 Composition of mill liner and grinding ball Composition (wt%) C Mn Si Cr Mo P S Mill liner 045 075 050 200 045 127 mm diameter grinding balls 080 085 060 050 003 Effect of impact on the grinding media and mill liner in a

Enhancement of taconite crushing and grinding through

1997年4月1日 The taconite samples have been used for further testing in order to try and investigate how far the effects of the blast induced microcracks can be traced These grinding tests were done on the 12 mm fraction using a smaller batch mill Each sample was first ground for 2 minutes and sieved2009年1月1日 The grinding setup refers to the socalled Malmberget method used at LKAB, characterized by a subsequent circuit of rod and ball mill grinding The highest P 80 values were obtained by grinding (PDF) Processing of Magnetite Iron Ores–Comparing Grinding Options2021年2月4日 Various types of Attritors fall in between these (See chart, Comparison of Grinding Mills, below) COMPARISON OF GRINDING MILLS TYPE OF MILL MEDIA SIZE RPM TIP SPEED (fpm) Ball Mill 1/2” and larger 1050 Attritor 1/8” to 3/8” 75450 6001000 Sand Mill/Horizontal mill 1/64” to 1/8” 8001200 20003000ATTRITORS AND BALL MILLS HOW THEY WORK Robert E

Vertimills

2020年3月31日 than 20 microns, and has standard mill sizes ranging from 15HP (11kW) to 4500HP (3352 kW) Mechanically, the Vertmill® is a very simple machine with an agitating screw suspended into the grinding chamber, supported by spherical roller bearings and driven by a fixed speed motor through a gearbox2019年11月4日 How taconite became a viable commercial product Identified in the late 19th century, it took the depletion of natural iron ores in Minnesota for lowiron taconite to come to the fore By Alex How taconite became a viable commercial 2023年11月3日 Though taconite was identified as an ironbearing rock on the Iron Ranges of northern Minnesota long before the 1950s, it wasn’t until then that it was extracted, processed, and shipped to steel mills on the Great Lakes As natural ore reserves diminished, taconite became an alternative source of iron that allowed the Iron Range to Commercialization of Taconite MNopedia

The clash of two big steel companies will help

2021年2月8日 This year it acquired the Big River steel works in Arkansas, the company’s first minimill, with $774 million in cash For generations, Mesabi iron ore has fed US Steel’s big blast furnaces But as the steel 2015年2月24日 Option 2 has an additional grinding and magnetic separation stage compared to Option 1 and is considered to be simple for design and operation The final milling stage is carried out using energyefficient stirred mills Steel grinding media usage significantly increases the operating cost Option 3Ecoefficient and costeffective process design for magnetite iron ore Contribute to dihog/ development by creating an account on GitHub/ very fine grinding mills for taconite oremd at main

The Taconite Breakthrough Port Authority

2023年5月5日 competitive edge that rich, natural ore had in the marketplace, but the Wizard of Menlo Park proved that magnetic separation of lowgrade iron ore was certainly feasible “Pebble mills” are used in taconite processing operations to perform the final grinding of fine particles prior to magnetic separation of highgrade iron ore from waste rockThe effects of percent solids, mill loading, and grinding time on product size distribution and ball wear were studied in a laboratory ball mill for a taconite ore Mild steel balls and HCLA steel balls were used to examine the role that ball hardness play in grinding Net production of −44µm (−325mesh) material reached maximum at 70% solids, whereas the ball wear Effects of percent solids and mill loading on ball wear in 2020年12月4日 Results showed that the P 80 of grinding products decreased from the 291 mm for the first set to 142 and 073 mm for the other two sets of samplesBlastingcrushinggrinding: Optimisation of an

Electrochemical aspects of grinding mediamineral

1984年6月1日 In a grinding mill, ore particles dispersed in a slurry and the steel grinding media are in continuous motion At the same time, fresh mineral surfaces are generated due to size reduction while the ball surfaces also undergo differential abrasion Results from laboratory grinding tests on a magnetic taconite ore sample (with magnetite as 2015年3月21日 The process of enriching taconite ore involved grinding the ore to remove gangues and upgrading the iron ore (ie, an ore beneficiation process) The resultant high grade ore is in the form of fine particles, as small as 01 mm or less, which are not suitable for sintering This issue led to the development of the pelletizing processUnderstanding Pellets and Pellet Plant Operations – IspatGuru1982年3月1日 This paper reviews the recent work on the use of low molecular weight anionic polymers as grinding additives for wet grinding of minerals Laboratory results on the increase of breakage rates are given, and conclusions drawn regarding the mechanism of the effect An experimental procedure is given for testing additives in a laboratory ball millChemical additives for wet grinding of minerals ScienceDirect

Ball Mill an overview ScienceDirect Topics

Ball mills tumble iron or steel balls with the ore The balls are initially 5–10 cm diameter but gradually wear away as grinding of the ore proceeds The feed to ball mills (dry basis) is typically 75 vol% ore and 25% steel The ball mill is operated in closed circuit with a particlesize measurement device and sizecontrol cyclones2017年7月20日 Autogenous grinding is favored when the ore is quite competent and a fine grind is required Semiautogenous grinding is applied when fine crushing could cause severe problems or when ore is variable Autogenous Grinding Semi Autogenous Some companies ship the ore to other sites for further processing Before the ore can be concentrated, it must be reduced to "liberation" sizebetween 8o and go per cent 325 mesh, the fineness of face powder This is done by running The Mining of Taconite, Lake Superior Iron Mining

(PDF) Iron ore pelletization ResearchGate

2015年12月31日 Arrium Australia 0810 0810 0440 440 Iron Ore The pelletizing process involves the preparation of ra w materials; the proportioning and mixing of raw materials; the formation, preheating, and 2002年8月1日 Wiegel, RL, 2000, “Development of an approach to the simulation of size reduction/mineral liberation for magnetic taconite ore in tumbling mills and its implementation in a BASIC computer program,” University of Minnesota Duluth, Coleraine Minerals Research Laboratory Technical Report #CMRL/TR0016 Google ScholarSize reduction/mineral liberation simulation for a magnetic taconite mineral grain size of iron in taconitemineral grain size of iron in taconite mineral grain size of iron in taconiteNorth America The economy continent BritannicaNorth AmericGitHub

Consumption of steel grinding media in mills – A review

2013年8月1日 Likewise, Hebbar (2011) has studied the grinding wear behaviour of austempered ductile iron as media material in the comminution of Kudremukh haematite iron ore in a ball mill The grinding experiments were conducted under different pH conditions, ie pH = 70 and pH = 85, while keeping other parameters fixed, at a mill speed of 74 2020年11月5日 Structure of the ore to be concentrated affects grade and recovery of spiral products At the HillTrumbull plant two types of ore are treated in the spirals: Hard dense hematite with very little limonite and at times containing some taconite Very fine grinding would be required for complete liberation of silica from the iron oxideHumphreys Spiral Concentrator 911 Metallurgist3 kW, the grindability of a taconite ore was improved by 13 pet at a bulk temperature of 197 0c Because stress cracking occurred at a lower temperature, less energy was consumed The special laboratoryscale grinding device is a Bond ball mill manufactured by BicoBraun Inc, Burbank, CA Theby Microwave Heating CDC Stacks

Vertimill as the definitive step before concentration

2023年10月19日 3W is 35% more efficient than a lab scale ball mill for an iron ore An independent side by side study was performed on a 43 m x 69 m ball mill and VTM800WB Vertimill both using the same size2023年5月13日 They do this by tumbling the ore with 5inch steel balls and water inside a long cylinder that is 27 feet in diameter It takes 7,000horsepower motors to run these mills Eric Roper / Star TribuneInside the mines and megamachines of the Iron 2022年8月2日 The Planet Positive Vertimill ® grinding mills are expected to save more than 30% of the installed power compared to a conventional ball mill circuit “We are pleased that our customer has chosen the Outotec to deliver energyefficient

(PDF) Vertimill as the definitive step before concentration

2019年4月8日 In fine grinding applications, gravity induced stirred mills have a demonstrated higher energy efficiency compared to conventional tumbling ball mills, leading to their increasing utilisation in 2015年9月10日 The taconite ore processing industry produces usable concentrations of ironbearing material by removing nonferrous rock (gangue) from lowgrade ore The sixdigit Source Classification Code (SCC) for taconite ore processing is 303023 Table 11231 lists the SCCs for taconite ore processing Taconite is a hard, banded, lowgrade ore, 1123 Taconite Ore Processing US EPA1985年6月1日 Wet grinding in the presence of oxygen and pyrrhotite Grinding media wear for the three types of steel balls in the wet grinding of taconite and quartzite is illustrated in Table 3 The pH of the ore slurry in the grinding of taconite remained in the narrow range 81 84 in the presence and absence of pyrrhotiteCorrosive and abrasive wear in ore grinding ScienceDirect

1123 Taconite Ore Processing US EPA

2015年9月10日 semiautogenous or autogenous grinding mills (using larger pieces of the ore to grind/mill the smaller pieces), then to pebble or ball mills Ideally, the liberated particles of iron minerals and barren gangue should be removed from the grinding circuits as soon as they are formed, with larger particles returned for further grinding2016年5月24日 In place of initially grinding 85 to 90% minus 325, the grind if coarsened to 8085% minus 325mesh will result in greater initial tonnage treated per mill section Considerable advantage is to be gained by this approach FreeFlow “SubA” Flotation is a solution to the effective removal of silica from magnetic taconite concentratesBeneficiation of Iron Ore 911 Metallurgist2021年2月18日 semiautogenous or autogenous grinding mills (using larger pieces of the ore to grind/mill the smaller pieces), then to pebble or ball mills Ideally, the liberated particles of iron minerals and barren gangue should be removed from the grinding circuits as soon as they are formed, with larger particles returned for further grinding1123 Taconite Ore Processing US EPA

AP42 Background Document for Section 1123 Taconite Ore Processing

A simplified flow diagram of these processing steps is shown in Figure 21 Table 22 provides a key to the SCCs for taconite ore processing, as indicated in Figure 21 Liberation is the first step in processing crude taconite ore