عنا

مرحبا هل يمكنني مساعدتك؟

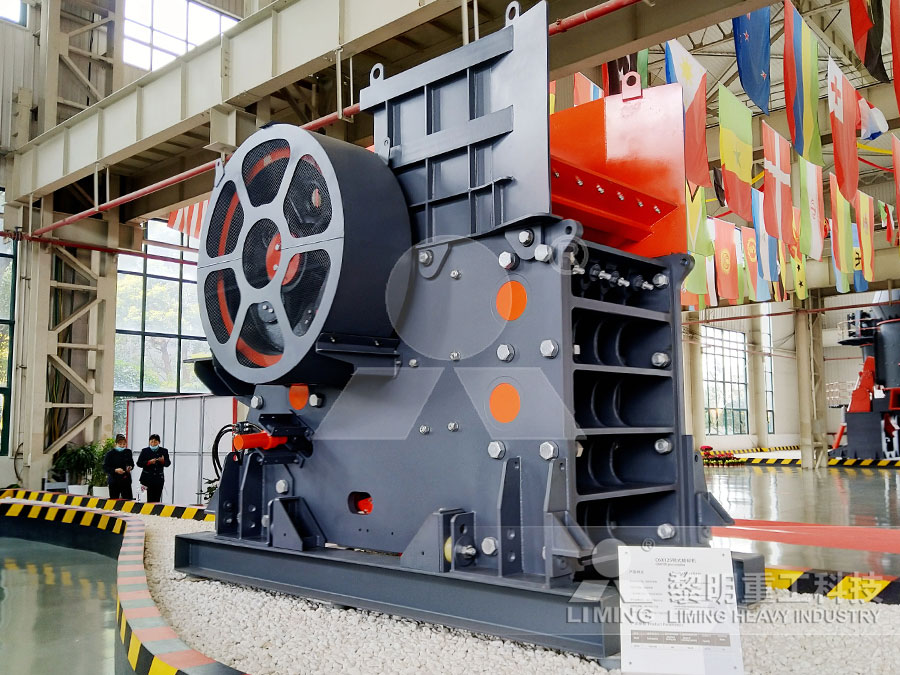

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

how to work roller grinding mill

2020-12-15T20:12:58+00:00

Revolution of Grinding Mill (Roller Body), Design,

2019年6月3日 Importance is roller grinding helps for control grinding due to line contact rather than space contact in chakki mills These rolls are normally 250/300 mm diameter and run opposite to each other 2015年9月14日 As an integral part of a modern roll maintenance program, roll grinding and balancing uses machinery with accurate inspection and measurement equipment This Practical Roll Techniques Grinding Balancing Valmet2018年10月30日 In the working process of Raymond mill, through introducing the principle of material comminution, it can be found that the machine mainly finishes the process of How to adjust the grinding roller of Raymond mill?

Roller mills: Precisely reducing particle size with greater

2020年11月11日 This article introduces roller mills and explains how they efficiently grind friable materials to a uniform final particle size while using relatively little energy2023年3月9日 roller grinding mill A roller grinding mill is a machine used to grind solid materials into fine powders It works by applying force to the material being ground How to work a roller grinding mill? LinkedInRaymond Mill Working Principle In the Raymond mill, a Raymond mill spring with a pressure of 10001500 kg is fastened to the grinding roll hanger After starting work, the grinding roller rotates around the main Raymond Roller Grinding Mill

Analysis and Optimization of Grinding

2022年1月23日 This work concentrates on the energy consumption and grinding energy efficiency of a laboratory vertical roller mill (VRM) under various operating parameters For design of experiments (DOE), the Most important of all, you should be very careful to avoid any scratches or damage to the working surface of the rolls The effectiveness of a triple roll mill depends considerably on the smoothness of the roll surfaces Set Understanding the Working and Best Practices for 2020年6月18日 The production capacity of vertical roller grinding mill is the prime concern question for user Generally speaking, the production capacity refers to grinding capacity How to compute capacity calculation of vertical roller grinding mill

How to Maintain My Raymond Mill to Improve the

2019年9月9日 Raymond grinding mill is to grind the material through the grinding of the rollers and rings If the feed quantity is too small, there cannot form a material cushion between the highspeed rotating roller and the 2018年8月17日 Rod Mills — these rotating mills use rods for grinding media causing friction and attrition between steel rods and ore particles Rod mills can accept feed up to approximately 50 mm (2 in) and Grinding Mills — Types, Working Principle 2019年9月9日 Raymond grinding mill is to grind the material through the grinding of the rollers and rings If the feed quantity is too small, there cannot form a material cushion between the highspeed rotating roller and the How to Maintain My Raymond Mill to Improve the

Three Roll Mill Franli Machine

The three roller mill is suitable for the grinding of ink, paint, paint, lipstick, chocolate, soap, and other materials, and it is mainly composed of a roller, a machine base, a guide cover, a discharge knife plate, a feeding copper Raymond Mill Working Principle In the Raymond mill, a Raymond mill spring with a pressure of 10001500 kg is fastened to the grinding roll hanger After starting work, the grinding roller rotates around the main shaft and rolls close to the grinding ring under the action of the Raymond mill spring and centrifugal forceRaymond Roller Grinding MillThe Raymond® Roller Mill is an airswept vertical ringroll mill with an integral classification system that simultaneously dries, pulverizes and classifies a number of different types of products including limestone, clay, minerals and others From a feed ranging in size from approximately ½ 2in / 1050mm, the roller mill can produce Raymond® Roller Mill airswept vertical ringroll Schenck

Roller Mills: What They Are Why They're Great Automatic

2021年2月16日 Updated: Apr 29, 2021 Today's roller mills are an essential part of the American food production chain Modern flour production depends on the use of grain roller mills to reduce wheat berries into flour In addition, roller mills are vital to the processing of other grains, including the most important grain in the US today: cornSimply put, the roller press is the most energyefficient grinding machine on the market Since its commercial introduction into the cement industry by KHD in the 1980s, hundreds of them have been installed in the cement and minerals industries, in both finish and semifinish applications And with the lowest specific energy consumption among comparable Roller Press KHD Humboldt WedagFor raw material grinding a quadropol® vertical roller mills QMR² 45/23 was contracted to serve the kiln line, while for cement grinding two identical QMC² 45/23 were considered for grinding different cement types The request for interchangeable parts for the three mills was fulfilled and represents still a holistic approach quadropol® thyssenkrupp Polysius

BTMA–What is wet pan mill and how does wet pan mill work?

2023年1月6日 Working Principle of Wet Pan Mill First, the motor transmits the power to the reducer, then the central drive shaft transmits power to the horizontal axis, and finally the roller moves counterclockwise to grind the material into fine particles in the wet mill When the rollers are rolling and kneading the minerals, the materials are fully 2017年10月27日 The power ingesting of a grinding process is 5060% in the cement production power consumption The Vertical Roller Mill (VRM) reduces the power consumption for cement grinding approximately 3040% associated with other grinding mills The process variables in cement grinding process using VRM are strongly nonlinear and PROCESS CONTROL FOR CEMENT GRINDING IN The Raymond® fine grinding roller mill (US Patent Nos and ) was specifically designed to achieve a product size distribution with d50 measurement of less than 10 microns Available as new roller Raymond® Fine Grinding Roller Mill Schenck

5 Facts About Thread Rolling Production Machining

2021年7月6日 5 Increase in Tensile Strength Cold working increases tensile strength at least 30% more than cut threads, which increases the strength of the thread Additionally, rolled threads improve fatigue 2022年12月29日 Roller mills work well, as most of you know, down to a certain particle size Then your roller mill simply operates with the rolls too close together and maintenance issues rear their ugly head That dictates when to utilize hammer mills The triple roller mill was placed over the grinder with bypass options The system could use any or all Hammer Mill or Roller Mill: Advantages Disadvantages 15:17:25 Threeroll mill for short, threeroll mill can be divided into two types: experimental threeroll mill and production threeroll mill The threeroll mill is suitable for the manufacture of slurries such as paints, inks, pigments, and plastics The working principle of the threeroller grinder: The threeroller grinder Something You Should Know about Three Roller Grinding Mill

Best practices for safe and efficient three roll milling Mixers

2023年11月3日 Do not run the mill dry When product has almost run through, open the rolls and disengage the apron Do not wear loose articles of clothing or any accessories that can get caught in the rolls Roll journals are equipped with ball or roller bearings It is good practice to lubricate the bearings on a monthly basis2022年6月24日 4 Grinding process In the ball mill, the material is mainly crushed by impact and friction In the vertical grinding mill, the material is mainly extrusion, and grinding is the auxiliary The residence time of the material in the vertical mill is 23 minutes, while in the ball mill it takes 1520 minutesHow to choose between ball mill and vertical roller mill?2020年5月30日 Industrial grinders, of the sort used to produce espresso pods or supermarket packs of preground coffee, are more or less exclusively roller mills The most sophisticated of these grinders can grind coffee without significantly heating the grounds, and in the process produce very narrow particle size distributions with minimal fines This Benchtop Roller Mill? Barista Hustle

Roller Mills Milling Group

Gupfenstrasse 5 Uzwil 9240 Switzerland roller mills consistently and safely grind wheat, corn, rye, barley, spelt and other grains We offer a wide range of roller mills and optional functionsbean mill G8 for animal feed rice corn Production capacity: 25,000 kg/h 40,000 kg/h The Rivakka Greenmaker G8 is a tractordriven roller mill for fresh or dry grain The mill 's serratededged, hardened rollers effciently pull grain inside and carefully Roller mill, Roller grinding mill All the agricultural 2023年2月15日 Removal steps of the grinding roller of Raymond mill 1 Remove the protective cover on the left side of the Raymond mill body, the Vbelt and the double pulley on the fast roller shaft 2 Remove the gear Raymond Roller Mill PartsUltimate Guide Fote

Stationary Roller Mills and Corn Crackers Horning

The smallersized Horning mill is just perfect for small farmers and mills This fella packs a big punch for its size, featuring a 2belt drive with output volumes from 250 to 330 bushels per hour It is available with a 5HP 2020年3月31日 Up until the late 19th century, most millers used mill stones to mill the wheat into flour Mill stones always come in a pair Both are large round stones, with a flat top and bottom and are incredibly heavy The Where Your Flour Comes From Roller Stone 1 天前 Grinding Mills: Ball Mill Rod Mill Design Parts Common types of grinding mills include Ball Mills and Rod Mills This includes all rotating mills with heavy grinding media loads This article focuses on ball and rod mills excluding SAG and AG mills Although their concepts are very similar, they are not discussed here Photographs of a glass ended Grinding Mills 911 Metallurgist

Raw Material DryingGrinding Cement Plant Optimization

Ball mills for cement raw material and coal equipped with a drying compartment adequately air swept with hot gas (2535M/sec above the ball charge), can handle moisture about 8% Fully air swept mills (56M/sec) can dry up to 1214% moisture Grinding Operation Objectives and KPIs: Highly energy intensive unit operation of size reduction in A vertical grinding mill consists of the following components: Electric Motor to rotate the grinding table The electric motor is often a three phase variable speed drive (VSD) induction motor, but designs vary Reduction Gearbox to reduce the rotational speed of the incoming motor shaft prior to a secondary shaft connecting to the grinding Vertical Grinding Mill (Coal Pulverizer) Explained saVRee2017年6月19日 Abstract: As a worldwide leader in grinding solutions for the cement industry and understanding the changing needs of cement producers and how to tailor solutions to meet those needs Optimizing output, improving efficiency, and reducing CO2 emissions while keeping investment costs to a minimum are common challenges that the Grinding process optimization IEEE Xplore

Hammer Mill Principle, Construction, Working, and More

1 天前 Hammer Mill Principle, Construction, Working, and More A hammer mill is an essential machine in the pharmaceutical and food processing industries It can be used to crush, pulverize, shred, grind and reduce material to suitable sizes In a hammer mill, swinging hammerheads are attached to a rotor that rotates at high speed inside a hard 2023年11月2日 Grinding mills are mainly used in metallurgy, building materials, chemical engineering, mines and other fields The grinding mill is a collective word which can be classified into the vertical grinding mill, the pendulum roller mill, the superfine grinding mill, the trapezoidal grinding mill, the mediumspeed grinding mill and so onGrinding Mill Grinding Mills Manufacturer Industrial 2017年6月2日 High pressure grinding rollers (HPGR), also referred to as a roller mill or roller press, pulverize material as it moves between two large rollers rotating in opposite directions or a roller and a flat surface The rolls can be serrated, toothed or smooth Hammer mill Impact mills are similar in construction and principal to HSI and VSI How it Works: Crushers, Grinding Mills and Pulverizers

Roller Mill Springer

2023年7月4日 Roller mill is a type of grinding equipment for crushing materials by pressure between two or more rolling surfaces or between rolling grinding bodies (balls, rollers) and a track (plane, ring, and Roller Mill, Fig 3 Working principle of highpressure roller mill 4 Roller Mill the fan and the host, and enters the small cyclone2023年10月28日 Particle Processing and Powder Milling Equipment Microfluidics Liquid Nano Particle Size Reduction Quadro Liquids Liquids Processing and High Shear Mixers Steridose Bioprocess Equipment for Fitzpatrick Powder Milling Equipment2022年1月23日 mill, coal mill, Clinker Mill and cement mill, and the vertical mill occupies a large energy consumption unit Therefore, it is necessary to optimize the multiobjective parameters of the VRM in order to improve the grinding performance and reduce energy consumption The present work focuses on the grinding performance of an overflow Roller Mill Based on Experimental Method mdpires

Hydraulic system vertical roller mill operation PDF

2015年3月24日 1The working principle of the hydraulic system vertical roller mill The hydraulic system ofvertical mill is an important system, the main function ofthe hydraulic system is to break the grinding roller, which is when the internal grinding cavity wear parts wear, can stop open on both sidesofthe grinding roller mill, to replace the inside parts or 2021年7月11日 An air classifier mill applies impact grinding and air classification in one step The mill uses airflow to convey feed material to the mill’s grinding chamber, classifies the material into fine and coarse fractions, recirculates the coarse fraction for further grinding, and conveys fine particles out of the mill, all in one continuous How to operate an air classifier mill to meet your fine 2010年2月28日 Roller mills, particularly single pass installations, require more care and attention than hammermills in order to achieve a consistent and accurate grind Ensuring the feed is spread thinly across the face of the roller mills can present some problems as mechanical feed gates can easily become obstructed, impairing the smooth and regular Hammermills versus roller mills WorldGrain

Raymond Mill History, Working Principle Applications

2023年11月2日 The Raymond Mill is a grinding machine, suitable for the preparation of various kinds of mineral powder and coal powder preparation has launched three upgrade series of Raymond Mills, MB5X Pendulum Roller Mill, MTW European Grinding Mill and MTM Mediumspeed Grinding Mill respectively2020年3月1日 1 Introduction Grain milling might be the oldest manufacturing process in the world Archaeologists have found drawings, dating back to 2600 BC, of the basic process of rubbing or grinding using two stones on the walls of Egyptian tombs (Walker Eustace, 2016)Grinding (milling) of cereal grains is the fundamental operation currently Stone milling versus roller milling: A systematic review of the 2022年11月30日 Advantages of Roller Mills 1 Produce more uniform, fewer fines, and oversized particles when it comes to product quality 2 Generates less heat (0 – 3 0 C) unlike hammer mill that generates up to 10 0 C 3 Less moisture loss 4 Better work environment due to low machine noises levelRoller Mill: Components, Designs, Uses, Advantages and

ThreeRoll Mills Grinding and Dispersing Group

Our threeroll mills offer the reliability, high raw material yield and gentle dispersion of contamination, as well as the temperaturesensitive products you need for quality grinding and dispersing Our mills offer a broad range of roll materials and concepts to meet all your applications, including cleanroom production to international 2018年8月17日 Rod Mills — these rotating mills use rods for grinding media causing friction and attrition between steel rods and ore particles Rod mills can accept feed up to approximately 50 mm (2 in) and Grinding Mills — Types, Working Principle 2019年9月9日 Raymond grinding mill is to grind the material through the grinding of the rollers and rings If the feed quantity is too small, there cannot form a material cushion between the highspeed rotating roller and the How to Maintain My Raymond Mill to Improve the

Three Roll Mill Franli Machine

The three roller mill is suitable for the grinding of ink, paint, paint, lipstick, chocolate, soap, and other materials, and it is mainly composed of a roller, a machine base, a guide cover, a discharge knife plate, a feeding copper Raymond Mill Working Principle In the Raymond mill, a Raymond mill spring with a pressure of 10001500 kg is fastened to the grinding roll hanger After starting work, the grinding roller rotates around the main shaft and rolls close to the grinding ring under the action of the Raymond mill spring and centrifugal forceRaymond Roller Grinding MillThe Raymond® Roller Mill is an airswept vertical ringroll mill with an integral classification system that simultaneously dries, pulverizes and classifies a number of different types of products including limestone, clay, minerals and others From a feed ranging in size from approximately ½ 2in / 1050mm, the roller mill can produce Raymond® Roller Mill airswept vertical ringroll Schenck

Roller Mills: What They Are Why They're Great Automatic

2021年2月16日 Updated: Apr 29, 2021 Today's roller mills are an essential part of the American food production chain Modern flour production depends on the use of grain roller mills to reduce wheat berries into flour In addition, roller mills are vital to the processing of other grains, including the most important grain in the US today: cornSimply put, the roller press is the most energyefficient grinding machine on the market Since its commercial introduction into the cement industry by KHD in the 1980s, hundreds of them have been installed in the cement and minerals industries, in both finish and semifinish applications And with the lowest specific energy consumption among comparable Roller Press KHD Humboldt WedagFor raw material grinding a quadropol® vertical roller mills QMR² 45/23 was contracted to serve the kiln line, while for cement grinding two identical QMC² 45/23 were considered for grinding different cement types The request for interchangeable parts for the three mills was fulfilled and represents still a holistic approach quadropol® thyssenkrupp Polysius

BTMA–What is wet pan mill and how does wet pan mill work?

2023年1月6日 Working Principle of Wet Pan Mill First, the motor transmits the power to the reducer, then the central drive shaft transmits power to the horizontal axis, and finally the roller moves counterclockwise to grind the material into fine particles in the wet mill When the rollers are rolling and kneading the minerals, the materials are fully