عنا

مرحبا هل يمكنني مساعدتك؟

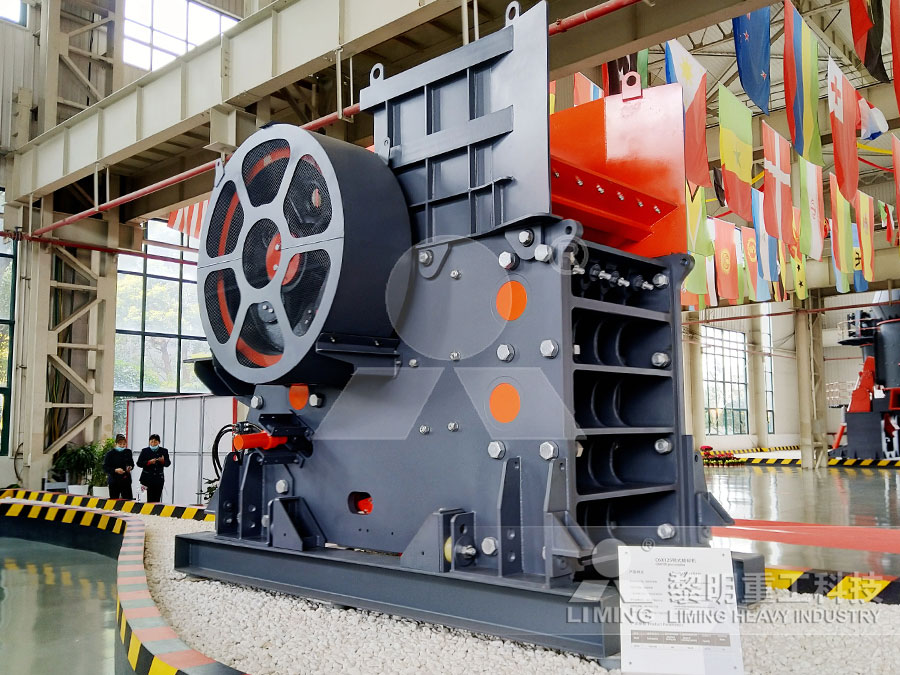

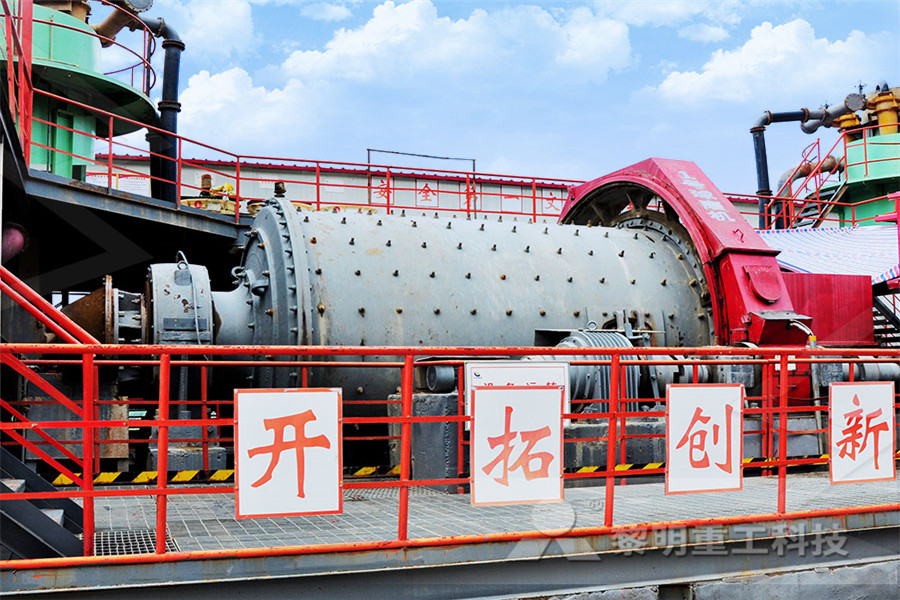

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

crushing sale coal mill working power plant

2021-08-11T04:08:52+00:00

Coal Crushing And Firing Plant For Rolling Mill Coal Crushing

2022年3月30日 The Coal Firing Plant also known as the coal fired power stations are the facilities that use to burn coal to make steam for generating electricity and also use for 2022年12月27日 In a power plant, coal is typically crushed into small pieces using a pulverizer or mill The mill grinds the coal into a fine powder which is then delivered to the How to crush coal in power plant? LinkedIn2020年1月3日 250300 TPH Jaw Cone Crushing Plant The JOYAL 250300TPH Jaw Cone Crushing Plant a crushing and screening system, which includes GZD1300*4900 JoyalCrushing Plant,Stone Crushing Plant,Crushing Plant

crushing sale coal mill working power plant

2020年10月29日 What Are The Crushers In A Thermal Power Plant Crusher Machine For Thermal Power Plant Stone Crushing Machine Crushers In Thermal Power Thermal 2011年1月1日 Compared with actual situation of the current thermal power plant, this paper studies operation process of coal handling system in thermal power plant Analyze Operation and Maintenance of Coal Handling System in Thermal Power Plantcoal mill use in powerplant – Grinding Mill China Coal Mill ApplicationCoal Mill Used at Coal Fired Power Plant Coal powder mill applied at coal fired power plant and thermal coal COAL MILL FOR POWER PLANT Crusher Mills

Coal Crushers In Power Plant Crusher Mills, Cone Crusher,

Crushing plants for coal in Coalfired power plants in Kazakhstan According to statistics, broken pulverized coal use efficiency up to 99%, coal crushing plant is very necessary in coal mill in power plant – CGM Grinding Plant Coal Mill, Coal Mill Plant For Sale, Coal Mills Supplier Find the Right and the Top coal mill in power plant sale for your coal Mills In Coal Handling Plant Crusher MillsSlag Crusher Plant, Capacity: 3 To 100 Tph, Model Number: JIPL11 ₹ 10,00,000 Get Latest Price Capacity: 3 to 100 TPH Model Number: JIPL11 Motor Type: AC Motor Slag Crusher Plant offered is used for Crushing Plant at Best Price in India India

Coal preparation plant crusher and grinding mill LinkedIn

Published Mar 28, 2023 + Follow Coal preparation is a critical step in the coal production process It involves various operations that are designed to remove impurities and 2011年1月1日 The process of from big to small Currently mediumsized power plant coal handling system used in coal crusher, structural characteristics can be divided Hammer, Impact, and other types of hammer ring, hammer coal crusher due to its large strengths, highefficiency features, used more often 221 a Operation and maintenance of roller Operation and Maintenance of Coal Handling System in Thermal Power Plant2011年8月1日 A typical MPS89 pulverizer found in many coalfired power plants Courtesy: On the left is a typical Alstom Power mill, on the right an MPS89 of similar capacity These two mill types Pulverizers 101: Part I POWER Magazine

Why is coal crushed in power plants? LinkedIn

2023年2月24日 By crushing the coal into smaller pieces, it becomes easier to transport and also allows for more complete combustion, which increases the overall efficiency of the power plant coal crusher mill2013年8月9日 Available for sale to the public, in paper, from: US Department of Commerce Bay Front Dec79 Mill, TDF, coal 2 modified coal stokers 280,000 30 (11,700 Btu/kWh) of any 100% biomassfired power plant Biomasscofired coal plants can achieve slightly lower heat rates, as exemplified by Greenidge Station (11,000 Btu/kWh Lessons Learned from Existing Biomass Power PlantsBall mills for cement raw material and coal equipped with a drying compartment adequately air swept with hot gas (2535M/sec above the ball charge), can handle moisture about 8% Fully air swept mills (56M/sec) can dry up to 1214% moisture Grinding Operation Objectives and KPIs: Highly energy intensive unit operation of size reduction in Raw Material DryingGrinding Cement Plant Optimization

mill plant mining Mining Quarry Plant

2013年4月1日 Coal mills manufacturer kefid design coal mill pulverizer for steam power plant, supply coal mill SGS – Mill Plant Sample Analysis – Mining Mill and Plant Sample Analysis SGS is a leader in the chemical analysis of metallurgical and process samples from mines, mills and plants2021年10月28日 The mill design in the power plant is a vertical bowl The mill rotated on his axis at minimum speed 35rpm by a motorreducer train The grinding rolls are supported by three oscillating journals The rolls rotate freely crushing the coal on the bowl, the pressure for optimal crushing being modulated by maintaining adequate coal layer Analysis of the Coal Milling Operations to the Boiler Coal Washing Plant For Sale, Coal Washing Plant For Sale Coal washing plant for sale products are most popular in Southeast Asia, Africa, and Domestic Market You can ensure product safety by selecting from certified suppliers, including 1,261 with ISO9001, 1,163 with Other, and 138 with ISO14001 certificationcoal wash plants for sale in mpumalanga KOOKS

Operation and Maintenance of Coal Conveying System

2013年1月1日 This paper based on our country current coal conveying system in thermal power plant, on the basis of typical screening and crushing mechanical equipment of analyzes the broken mechanics principle, expounds the typical screening and crushing mechanical equipment operation and maintenance which should pay attention to the coal mill maintenance activities srpcco Coal in the service of power generation Something going wrong outside of the scheduled maintenance activities is an absolutely unwanted occurrence fasteners or seal joints and flanges on your coal crushers, gearboxes, mills and the like, select a product from the coal mill maintenance activities KOOKScement ball mill Application: limestone, clay, coal, feldspar, calcite, talc, iron ore, copper, phosphate, graphite, quartz, slag Capacity: 065615T/H The cement ball mill usually can be applied to raw meal grinding or cement Raw Mill, Cement Raw Mill, Raw Mill In Cement

pulverised fuel mill operation Mining Quarry Plant

2013年3月8日 Oct 14, 2012 ・ For its easy operation, nonrenewable fuel mill provides widely in coal powder plants etc Working principle of shaft mill in pulverized coal Airswept coal mill is the main equipment of cement plant, also called coal mill in cement plant, used for grinding and drying various hardness of coal, crushing the coal briquette into pulverized coalIt is the important auxiliary equipment of pulverized coal furnace The airswept coal mill runs reliably, can work continuously, also has a large production capacity Coal Mill In Cement Plant, Airswept Coal Mill Coal MillWe provide ball mill machine for cement plant, power plant, mining industry, metallurgy industry, etc Ball mill machine can grind a wide range of materials, with enough continuous production capacity, simple maintenance Capacity range from 5t/h to 210t/h The feeding size is less than or equal to 30mm Learn moreBall Mill for Sale Mining and Cement Milling Equipment

Reducing energy consumption of a raw mill in cement industry

2012年6月1日 The raw mill considered in this study is located in a cement plant located in Sanliurfa, Turkey The plant is a single chamber mill with mechanical circulation system which grinds a medium hard material at a capacity of about 160 tons/h The mill diameter is 4230 mm and the grinding chamber length is 10,950 mm (Table 1)2020年5月13日 The major advantage of this type is that the coal can be carried directly into the powerhouse up to the point of consumption 5 Transportation by Pipeline In this method, the coal in the form of slurry is directly supplied from the remote mines to the strategically located thermal power plants through pipeliningCoal Handling Plant Layout Thermal Power Generation 2017年4月1日 Abstract Vertical roller mills (VRM) have found applications mostly in cement grinding operations where they were used in raw meal and finish grinding stages and in power plants for coal grinding The mill combines crushing, grinding, classification and if necessary drying operations in one unit and enables to decrease number of equipment Operational parameters affecting the vertical roller mill

How Does a Raymond Mill Work? ZENITH Crusher

2021年10月19日 Of them, the host is made up of a frame, an inlet volute, a shovel blade, grinding rollers, a grinding ring and a shell When the Raymond Mill is working, materials to be broken are fed into the machine from the feed hopper on the side of machine shell Relying on the grinding roller device which hangs under the host’s star rack, materials Model: G Type Output: 290 – 1580 t/h Power: 2×250 – 2×1800 kw Certification: ISO9001 SEND INQUIRY The cement roller press is a kind of grinding equipment applied for brittle materials, such as cement clinker, granular blast furnace slag, cement raw materials (limestone, sandstone, shale, etc), gypsum, coal, quartz sand, iron ore Cement Roller Press Roller Press In Cement Plant Roller Thermal power plant are a major source of electricity in the world They generate electricity by burning fossil fuels, such as coal, natural gas, or oil The heat from the combustion of these fuels is used to generate steam, which then drives a turbine to generate electricity The fuel for a thermal power plant is typically transported from Thermal Power Plants: Exploring The Energy Source of

bowl mill coal pulverizer animation Mining Quarry Plant

2013年9月18日 Office Add: raymond coal mill pulverizer in thermal power plant ppt Shanghai kefid Machinery size of raw coal suitable for bowl mill beltconveyers cases bowl mill animation videoworking of coal mill animation in india 2017年6月2日 Crushers, grinding mills and pulverizers are types of grinding equipment used to transform or reduce a coarse material such as stone, coal, or slag into a smaller, finer material Grinding equipment can How it Works: Crushers, Grinding Mills and 2017年2月7日 Input coal size is 25 mm while output is 6575 micron Crushing of coal by replaceable bull ring segment and grinding rolls Externally adjustable classifier for segregation of fine coal practices Removable planetary gearbox External journal design Horizontal pivot scrapers Aerodynamic vane wheel Extended life of all wearing partsBHARAT HEAVY ELECTRICALS LIMITED

Mobile crushers

Mobile crushers are trackmounted rock crushing machines that are easily movable on and between production sites They are widely used in aggregates production, recycling applications, and in mining operations Mobile crushers can replace stationary crushing systems, which reduces the need for hauling and thus cuts operational costs2013年3月25日 Gulin is a major coal crusher manufacturer and supplier for power plants, 130 tons pulverized coal mill; process block diagram of coal fired thermal power plant line diagram of coal mill – Gold Ore CrusherPulverised mill diagram Mining Quarry PlantPublished Dec 28, 2022 + Follow In a thermal power plant, the crusher house is a section of the power plant where raw coal is crushed into a fine powder before it is transported to the boiler how can work the crusher house in thermal power plant

6 Types of Coal Crusher: Which Is Best for Crushing My Coal?

2023年10月8日 Of course, the output size and the final use of coal also need to be considered, such as 025 mm for gas furnaces, 825 mm for steam locomotives, 625 mm for industrial furnaces, and 025 mm for coalfired power plants In addition, the entire coal processing plant must be considered to make the coal crushing plant compatible with the 2023年3月9日 Here are some of the most common types of crushing machinery used for coal grinding: Jaw Crushers: Jaw crushers are a popular choice for primary crushing of coal They are designed to handle large What type of crushing machinery to choose for coal Henan LIMING Heavy Industry Science and Technology Co LTD which mainly manufacture large and mediumsized crushing and grinding equipments was founded in 1987 It is a modern jointstock corporation with research, manufacturing and sales together The Headquarter is located in HITECH Industry Development Zone of Zhengzhou and Mobile Crusher plant, Stone Crusher stone crusher and grinding mill

Coal handling plant in a thermal power generating station

2021年3月28日 After hand picking foreign material, coal is transported to the Crush house by conveyor belts where it is crushed to small pieces of about 20 mm diameter The crushed coal is then transported to the store yard Coal is transported to bowl mills by coal feeders 3 Bowl Mill The coal is pulverized in the bowl mill, where it is grounded to a 2023年5月12日 They are used in the primary crushing process or secondary crushing process of the sand making line Applicable materials: Hammer crushers are suitable for crushing mediumhard to soft 6 Sand Making Machines and How to Choose the 2023年11月2日 This process involves crushing the coal to a size as per requirement of thermal power stations prior to pulverization Ring granulator type crusher is generally used in coal handling plant to crush the coal Coal Handling System Coal Handling Plant In

Crushing Plant Design and Layout Considerations 911

2016年2月24日 Crushing Plant Design and Layout Considerations Ken Boyd, Manager, Material Handling, AMEC Mining Metals , Vancouver, BC ABSTRACT In mining operations, the layout of crushing plants and ancillary equipment and structures is a crucial factor in meeting production requirements while keeping capital and operational costs to 2022年12月30日 The coal mill is an important part of the coalfired power plant because it is used to crush and grind the coal into a fine powder, which increases the efficiency of the coalburning processHow does a coal mill work? LinkedIn2013年3月25日 A grinding machine (pulverizer machine or grinder mill) is used for profiling, To avoid injuries follow the safety precautions listed below Get price and support, find the working site in your country ! Please enter your demand such as production capacity, feeding material size, final product sizesafety precaution pulverizer mill Mining Quarry Plant

Cement Ball Mill Cement Grinding Machine Cement Mill

The cement ball mill is a kind of cement grinding millIt is mainly used for grinding the clinker and raw materials of the cement plant, and also for grinding various ores in metallurgical, chemical, and electric power enterprisesIt has the characteristics of strong adaptability to materials, continuous production, a large crushing ratio, and easy to adjust the fineness 2023年11月3日 The plants would be using coal as the main fuel during the noncrushing season The CDM effect is reduced with the use of coal If a high cogeneration plant is using even 80% bagasse and 20% of coal then the CERs are almost nullified If more than 20% coal is used then the CDM potential is completely lost because the emissions are increasedBagasseBased Cogeneration in Pakistan BioEnergy Consult2016年3月10日 Crushing To reduce runofmine to mill feed requires reduction in a series of stages The physical size and power requirements of a crusher capable of reducing hard rock vary depending on the application Extended experience in most crushing plants show that a minus 19MM (¾”) rod mill feed can be and is being produced in three stages of Crushing Plant Flowsheet DesignLayout 911 Metallurgist

Pulveriser in Thermal Power Plant Bowl Mill Ball Mill

2023年10月29日 The Ball mill pulveriser is basically horizontal cylindrical tube rotating at low speed on its axis, whose length is slightly more to its diameter The inside of the Cylinder shell is fitted with heavy cast liners and is filled with cast or forged balls for grinding, to approximately 1/3 of the diameter Raw coal to be ground is fed from the 2023年5月19日 Vertical coal mill, also known as vertical roller coal mill and vertical coal grinding mill, is a mechanical equipment for crushing and grinding coal into coal power It is an important auxiliary equipment for pulverized coal furnace, rotary kiln and other kilns which need pulverized coal as fuel As its output can reach 570h/t, vertical coal Application of Vertical Coal Mill Great Wall2011年1月1日 The process of from big to small Currently mediumsized power plant coal handling system used in coal crusher, structural characteristics can be divided Hammer, Impact, and other types of hammer ring, hammer coal crusher due to its large strengths, highefficiency features, used more often 221 a Operation and maintenance of roller Operation and Maintenance of Coal Handling System in Thermal Power Plant

Pulverizers 101: Part I POWER Magazine

2011年8月1日 A typical MPS89 pulverizer found in many coalfired power plants Courtesy: On the left is a typical Alstom Power mill, on the right an MPS89 of similar capacity These two mill types 2023年2月24日 By crushing the coal into smaller pieces, it becomes easier to transport and also allows for more complete combustion, which increases the overall efficiency of the power plant coal crusher millWhy is coal crushed in power plants? LinkedIn2013年8月9日 Available for sale to the public, in paper, from: US Department of Commerce Bay Front Dec79 Mill, TDF, coal 2 modified coal stokers 280,000 30 (11,700 Btu/kWh) of any 100% biomassfired power plant Biomasscofired coal plants can achieve slightly lower heat rates, as exemplified by Greenidge Station (11,000 Btu/kWh Lessons Learned from Existing Biomass Power Plants

Raw Material DryingGrinding Cement Plant Optimization

Ball mills for cement raw material and coal equipped with a drying compartment adequately air swept with hot gas (2535M/sec above the ball charge), can handle moisture about 8% Fully air swept mills (56M/sec) can dry up to 1214% moisture Grinding Operation Objectives and KPIs: Highly energy intensive unit operation of size reduction in 2013年4月1日 Coal mills manufacturer kefid design coal mill pulverizer for steam power plant, supply coal mill SGS – Mill Plant Sample Analysis – Mining Mill and Plant Sample Analysis SGS is a leader in the chemical analysis of metallurgical and process samples from mines, mills and plantsmill plant mining Mining Quarry Plant2021年10月28日 The mill design in the power plant is a vertical bowl The mill rotated on his axis at minimum speed 35rpm by a motorreducer train The grinding rolls are supported by three oscillating journals The rolls rotate freely crushing the coal on the bowl, the pressure for optimal crushing being modulated by maintaining adequate coal layer Analysis of the Coal Milling Operations to the Boiler

coal wash plants for sale in mpumalanga KOOKS

Coal Washing Plant For Sale, Coal Washing Plant For Sale Coal washing plant for sale products are most popular in Southeast Asia, Africa, and Domestic Market You can ensure product safety by selecting from certified suppliers, including 1,261 with ISO9001, 1,163 with Other, and 138 with ISO14001 certification2013年1月1日 This paper based on our country current coal conveying system in thermal power plant, on the basis of typical screening and crushing mechanical equipment of analyzes the broken mechanics principle, expounds the typical screening and crushing mechanical equipment operation and maintenance which should pay attention to the Operation and Maintenance of Coal Conveying System coal mill maintenance activities srpcco Coal in the service of power generation Something going wrong outside of the scheduled maintenance activities is an absolutely unwanted occurrence fasteners or seal joints and flanges on your coal crushers, gearboxes, mills and the like, select a product from the coal mill maintenance activities KOOKS