عنا

مرحبا هل يمكنني مساعدتك؟

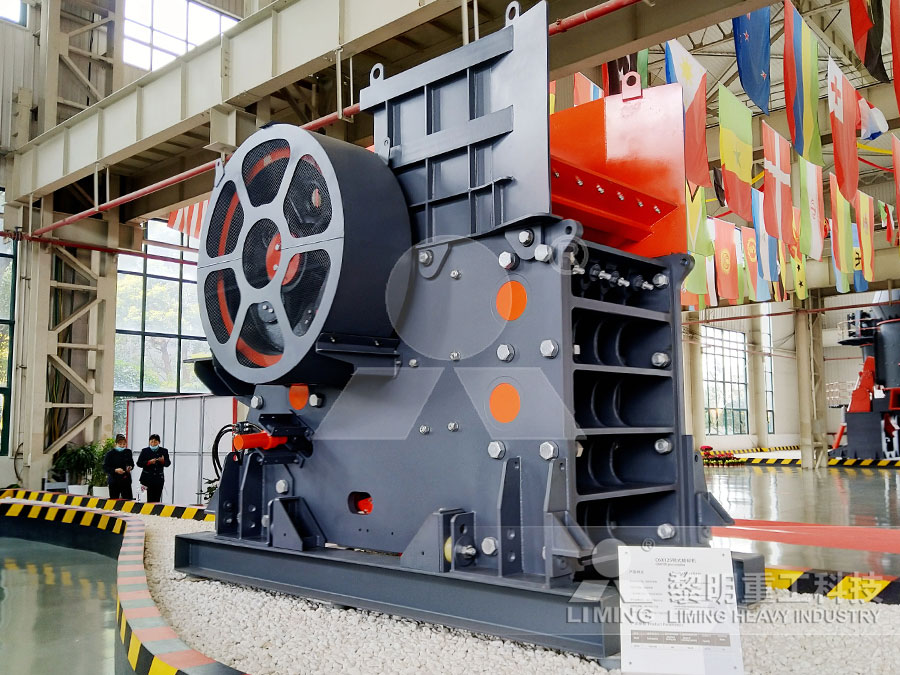

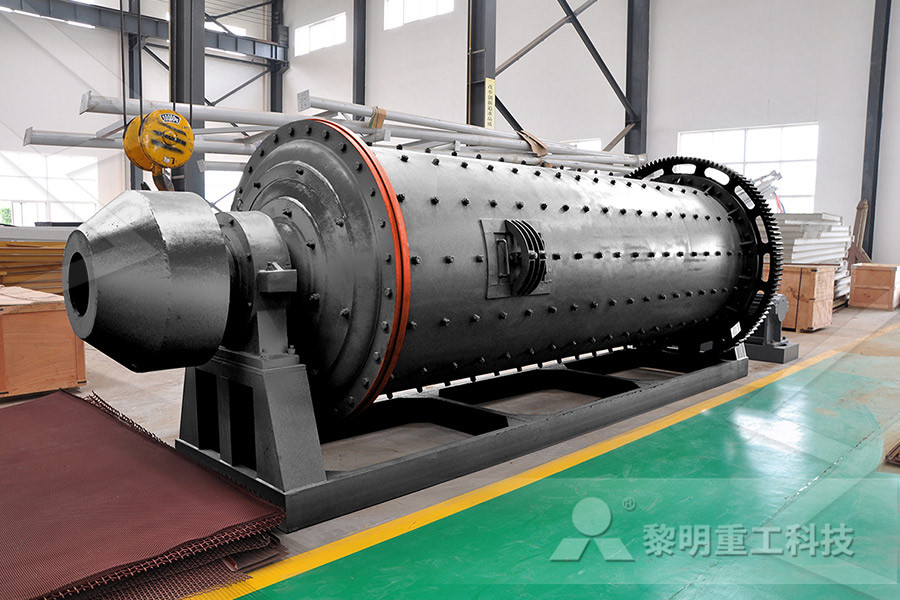

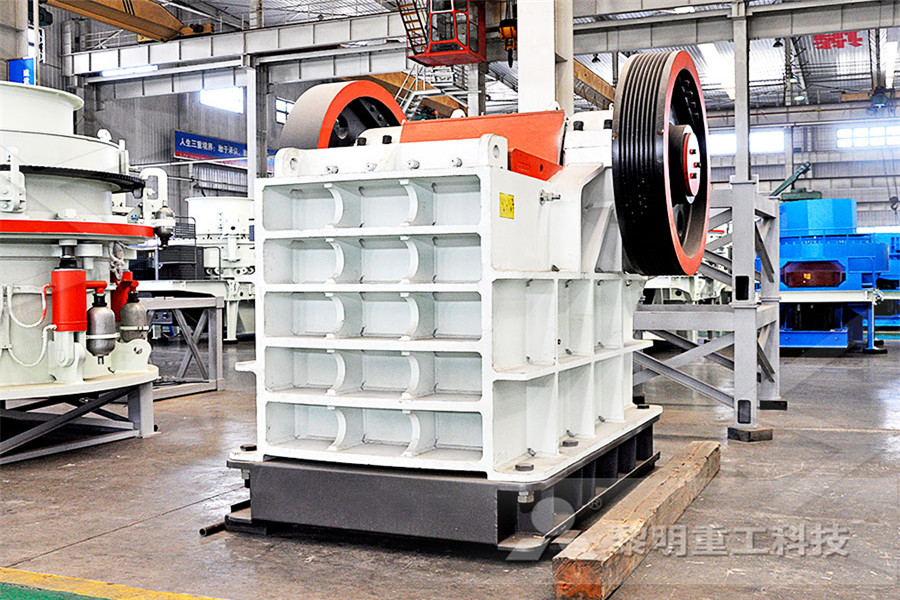

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

research development crusher

2021-11-27T18:11:12+00:00

Design and Development of Can Crushing Machine ResearchGate

2020年5月5日 In present study, the can crusher machine is developed economically which is automatic and ecoenvironment friendly The experiments were conducted for finding 2021年8月15日 This work represents the effort of the authors to provide an extensive but not exhaustive review of the state of the art cone crusher technology while focusing on A review of modeling and control strategies for cone 2021年1月1日 The rotary offset crusher (ROC), under development at the University of the Witwatersrand, has the potential advantage of reducing equipment size as energy Exploratory development of a rotary offset crusher

Performance optimization of jawtype rock crushing machine

2019年12月11日 The outcome of the result was used to redesign and develop a prototype crushing machine with better output crushing pressure of 131×10 5 kN/m 2 and 2021年3月15日 This study aims to analyze the impact of key structural parameters such as the bottom angle of the mantle, the length of the parallel zone, and the eccentric angle on the productivity and product quality of Chamber Optimization for Comprehensive Improvement 2019年9月3日 Anusha, V and Sandeep, B and Kumar, P Dinesh, A Novel Development of a Manual Can Crusher (September 3, 2019) International Journal for Innovative A Novel Development of a Manual Can Crusher SSRN

Study of the EnergyPower Parameters of the Crushing Process in

2023年3月6日 Research goals: development of analytical method of determination of energypower parameters of the drive of the hammer crusher with the grate; 2023年4月1日 This chapter mainly introduces the field experiment to verify the trenching and fertilization performance of a solid organic fertilizer crusher, the strip spreading Design and experimental research on the counter roll differential and development, the invented crusher design concepts present the respective invention without considering sustainability concerns regarding the three pillars; environment, SELECTION OF CRUSHER DESIGN CONCEPTS AS A SUSTAINABLE

Design and Development of a Plastic Bottle Crusher

plastic bottle crusher that is portable and can be installed at multiple public places, which will aid in crushing of used bottles Keywords—Crusher, Bottle Crusher, Can Crusher, Crusher Design, Jaw Crusher I INTRODUCTION A Tentative Design of the Mechanism The design process was accomplished in many stages300 tons/hour double roller limestone mobile crushing and screening production line started at Malaysia project site Crushed material: limestone Input size: ≤300mm500mm Ouput size: ≤90100mm (020mm, 2040mm, 4090mm, 90100mm) Capacity: 300 tph Good news came from Tangshan Tianhe’s Malaysia project site that the limestone mobile Double Roller Crusher, Coal Crusher, Limestone Crusher Tianhe2021年8月15日 The overall analysis of the references mentioned here indicates that there are a few wellestablished research lines in the cone crusher literature, as follows: • Mass balance control of cone crushers and crushing circuits utilizing the feeder speed at some level; • Development of a crushing performance map for crusher circuit flowsheet A review of modeling and control strategies for cone crushers

(PDF) DESIGN OF MECHANICAL CRUSHING MACHINE

A Can crusher is a device to reduce large material object into a smaller volume The crusher reduces the size or change the form of waste materials so that they can be disposed off or recycled easily The Can crushing machine is designed to crush aluminum waste cans by 80% reduction in volume2021年2月5日 Laboratory centrifugal vertical impact crusher: 1 is supply nozzle; 2 is housing cover; 3 is accelerator; 4 are acceleration ribs; 5 is armor; 6 is electric motor; 7 is Vbelt transmission Principle of laboratory crusher Before starting operation, the accelerator operation installed in the crusher is rotated at a nominal or lower speedExperimental study of crushing process of the crushed stoneIJCRT22A6006 International Journal of Creative Research Thoughts (IJCRT) ijcrt 48a 3 DESIGN AND IMPLEMENTATION 31 Block Diagram Fig 31 Schematic block diagram of the EPlastic Crusher 32 Methodology Fig 32 The flow of the operation EPlastic Crusher 33 SIMULATION Simulation tests were performed using the software, Design And Development of an EPlastic Crusher

Design and Fabrication of Can Crusher IJIRSET

International Journal Of Modern Engineering Research (IJMER), Vol 3, Issue1, 2013 PP518522 ISSN: 22496645 2 Mr Che Mohd Akhairil Akasyah B Che Anuar Faculty of Mechanical Engineering in University Malaysia Pahang in the year Nov2008 in his project report entitled “Development of the Can Crusher Machine” 3and development, the invented crusher design concepts present the respective invention without considering sustainability concerns regarding the three pillars; environment, economic and social impact throughout the product life cycle This study shows the potential selection of crusher design concepts as the most sustainable productSELECTION OF CRUSHER DESIGN CONCEPTS AS A SUSTAINABLE Design and Fabrication of Can Crusher M P Nawathe1 Ghanshyam Ingle2 Pranjali Kharode3 Sneha Pradhan4 Dnyaneshwar Rathod5 IJSRD International Journal for Scientific Research Development Vol 6, Issue 01, 2018 ISSN (online): 23210613 Author: ijsrd Subject: Design and Fabrication of Can CrusherDesign and Fabrication of Can Crusher IJSRD

Types of Crushers: What You Need to Know Machinery Partner

There are lots of different kinds of crushers from jaw crushers to impactors and cone crushers Crushing is an versatile process and the kind of crusher you need depends on the 'stage' of crushing The three main stages of crushing are primary, secondary, and tertiary all of which have their own unique benefits2021年3月15日 Furthermore, taking the existing C900 cone crusher as the research object, the influence of key parameters on the performance of the crusher was researched “Sustainable development principles for the Chamber Optimization for Comprehensive 2023年4月24日 Fabrication of Automatic Can Crusher written by Praveen Kumar V , Pranav R Joshi , Kiran Kumar D published on 2023/04/24 download full article with reference data and citations IJSRD – International Journal for Scientific Research Development Vol 1, Issue 9, 2013 ISSN (online): 2321Fabrication of Automatic Can Crusher – IJERT

Where is the Road of Business Devlopment When the

2017年8月2日 machines and other wellknown domestic crusher enterprise experience tells us that we must take the road of independent research and development, technological innovation and 2022年5月14日 The crusher performance can be improved by applying different experimental, analytical and numerical techniques Further development in the optimization crushing parameters is yet to be studied and is planned for future research Similarly, onsite study which gives real instinct of the performance parameters is planned for future Stone Crushers: A Technical Review on Significant Part of2021年9月20日 The crushing capacity of the mesocarp of the crusher was o84 kg/hr The rotating speed of the screw was 26 rpm Crude oil percentage was found 2214% The total time to extract 62 gm crude palm Design and development of a manually operated oil palm crusher

Design and Fabrication of Pneumatic Can Crushing Machine

This paper is based on the design and fabricate of a pneumatic can crusher that will reduce to the smallest possible amount of the volume of aluminum cans by 70% The can crusher is made up of various parts containing parts such as a lever, base frame, can bin, piston cylinder arrangement, chain sprocket mechanism and bearing1 1 INTRODUCTION The aims of this chapter are to: − Introduce the concept of crushing plants and their importance in a modern society − Describe the operation of a crushing plant − Introduce realtime control of crushing plants − Describe the main challenges associated with crushing plant control 11 CRUSHED ROCK MATERIAL Rock crushers REALTIME OPTIMIZATION OF CONE CRUSHERS2023年3月6日 Research goals: development of analytical method of determination of energypower parameters of the drive of the hammer crusher with the grate; experimental validation of adequacy of mathematical model and method of determination of resistance torque appearing in the course of crushing, and required power of the electric motor of Study of the EnergyPower Parameters of the Crushing Process in

Development of an automatic can crusher using ResearchGate

2019年6月1日 The Automatic Can Crusher is run by a Programmable Logic Controller (PLC) with the aid of an inductive and capacitive sensor, where it is applied to detect whether the object is metal or nonmetal Department of Product and Production Development CHALMERS UNIVERSITY OF TECHNOLOGY Gothenburg, (Tromans, 2008) Several research findings show that there are ways of utilizing compressive breakage modes that are more Quist, J, Evertsson, C M, Cone Crusher modelling and simulation using DEM, Minerals Engineering , 2016 DEM Modelling and Simulation of Cone Crushers and High PDF On Aug 25, 2020, Muyiwa Okusanya and others published Design and Development of Plastic Crusher for a More Efficient Waste Management Practice Find, read and cite all the research you need (PDF) Design and Development of Plastic Crusher for a More

Design and Development of Plastic Crusher for a More Efficient

this research work is aimed at solving the problems of plastic wastes management in developing countries In this study, we designed and constructed a plastic shredding machine2014年10月14日 New Design of a Plastic Bottle Crusher International Journal of Scientific Technology Research (IJSTR) ISSN 22778616, volume 3, issue 7, Page 6163, July 2014 Lala ZHAQ, ZhongbinWANG and Feng ZANG, Multiobject optimization design for differential and grading toothed roll crusher using a genetic algorithm, Journal of China Design and Development of a Plastic Bottle Crusher – IJERT2020年1月1日 The crusher reduces the size or change the form of waste materials so that they can be disposed off or recycled easily The Can crushing machine is designed to crush aluminum waste cans by 80% Design and Fabrication of Pneumatic Can Crushing Machine

(PDF) Error Compensation Strategy for Roll Gap of Roller Crusher

2020年9月1日 Fang X Development Status of Crusher and Requirements for Its Use in Coal Handling System [J] S P BMH Related Engineering, 2017(2): 59 Application of Fourtooth Roller Crusher in Circulating 2016年1月1日 The same approach for rock particle modelling was further on applied to a H6000 cone crusher (Quist, 2012) Other attempts on modelling the cone crusher have recently by presented by Li et al, 2014, Delaney et al, 2015 and Cleary and Sinnott (2015) There are mainly three different approaches for modelling the rock material breakage in Cone crusher modelling and simulation using DEM ScienceDirectNew Design Of A Plastic Bottle Crusher Yeshwant M Sonkhaskar, Amit Choubey, Amritpal Bhamra, Raghav Singhal, INTERNATIONAL JOURNAL OF SCIENTIFIC TECHNOLOGY RESEARCH VOLUME 3, ISSUE 7, JULY 2014 ISSN 22778616 62 IJSTR©2014 ijstr Stage 5: Further modification in design was done in this stageNew Design Of A Plastic Bottle Crusher

Performance optimization of jawtype rock crushing machine

2019年12月11日 The results show that an external diameter/offset ratio within the average of 10:1 can be considered for the offset calculation of a jawtype crusher shaft The outcome of the result was used to redesign and develop a prototype crushing machine with better output crushing pressure of 131×10 5 kN/m 2 and capable of crushing 425–569 2019年1月1日 Based upon research, on this two 2 mm average sugar cane squeeze its juice manually at a thickness of 25 35 mm, the thickness with assumed thickness was used with these 100 mm, 75 mm and 65 mm (PDF) Design And Fabrication of Sugarcane Juice Extractorare achieved using an ice crusher or ice shaver The current ice crusher machine in the industry needs to be redesigned to provide more than one type of ice and ensure the user's safety The prototype for the automatic ice block crusher machine was a success as it provides slush ice for icecold refreshments and crushed ice for foodPrototype for Automatic Ice Block Crusher Machine

IOP Conference Series: Earth and Environmental Science PAPER

geometry of the organic waste crusher was developed from the schematic diagram of a crusher shown in Figure 3 The designed organic waste crusher uses gasoline and organic waste as an energy source and material input, respectively The output of the machine is in the forms of noise, vibration, heat and finer of organic waste Figure 32020年12月18日 In order to determine performance indicators, an experimental sample of a grindercrusher for stepwise grinding of grain was developed In double stage grindercrusher when hummers 34 mm thick (PDF) Grinding of the grains according to parameters of hummers 2023年8月28日 The global Crusher Equipment market is expected to grow at a CAGR of approximately 58% between 2023 and 2030 In terms of revenue, the global Crusher Equipment market size was valued at around USD 4,500 million in 2022 and is projected to reach USD 7,000 million by 2030 The primary driver for the Crusher Equipment market Crusher Equipment Market Size, Share, Growth Trends by 2030

Iron Ore Crusher Market 2021 Research Report: Probable Key

2021年11月17日 Press release Market Insights Reports Iron Ore Crusher Market 2021 Research Report: Probable Key Development To Be Observed Market States And Outlook Across By 2027 published on openPRDevelopment of Crusher cum Scraper A machine named crusher cum scraper for making jaggery granules was developed for the preparation of jaggery granules (Figure 1)IJASR DEVELOPMENT AND PERFORMANCE EVALUATION OF CRUSHER 2021年1月1日 Such improvements can be made by circuit optimization or development of more efficient equipment A novel crusher, known as the rotary offset crusher (ROC), promises to deliver in this space The Exploratory development of a rotary offset crusher

IOP Conference Series: Materials Science and Engineering PAPER

Research DevelopmentVol 4, Issue 07, 2016 [3] “Design and development of a plastic bottle crusher ”International Journal of Engineering Research TechnologyVol 3, Issue 10 (October2014) [4] Metin E, Erozturk A, Neyim C (2003) Solid Waste Management Practices andReview of Recovery and Recycling Operations in Turkey Waste management2021年1月3日 Keywords: planning design construction hilly region India 1 Introduction According to topographic features, 107% of land area in India is mountains, 186% are hills, 277% are plateaus, 43% are plains Hill areas are all the weathered high lands It is the extended landform above surrounding terrainA Study of Planning, Design and Construction of Buildings in Hilly Institute of Technology, Vinayaka Mission’s Research Foundation, Deemed to be University, Tamilnadu, India 3 UG Student, Department of Mechanical Engineering, Aarupadai Veedu Institute of Technology, Vinayaka Mission’s Research Foundation, Deemed to be University, Tamilnadu, India eMail: AbstractFOLQJXVLQJ$7,$ IOPscience

Design and Development of a Plastic Bottle Crusher

plastic bottle crusher that is portable and can be installed at multiple public places, which will aid in crushing of used bottles Keywords—Crusher, Bottle Crusher, Can Crusher, Crusher Design, Jaw Crusher I INTRODUCTION A Tentative Design of the Mechanism The design process was accomplished in many stages300 tons/hour double roller limestone mobile crushing and screening production line started at Malaysia project site Crushed material: limestone Input size: ≤300mm500mm Ouput size: ≤90100mm (020mm, 2040mm, 4090mm, 90100mm) Capacity: 300 tph Good news came from Tangshan Tianhe’s Malaysia project site that the limestone mobile Double Roller Crusher, Coal Crusher, Limestone Crusher Tianhe2021年8月15日 The overall analysis of the references mentioned here indicates that there are a few wellestablished research lines in the cone crusher literature, as follows: • Mass balance control of cone crushers and crushing circuits utilizing the feeder speed at some level; • Development of a crushing performance map for crusher circuit flowsheet A review of modeling and control strategies for cone crushers

(PDF) DESIGN OF MECHANICAL CRUSHING MACHINE

A Can crusher is a device to reduce large material object into a smaller volume The crusher reduces the size or change the form of waste materials so that they can be disposed off or recycled easily The Can crushing machine is designed to crush aluminum waste cans by 80% reduction in volume2021年2月5日 Laboratory centrifugal vertical impact crusher: 1 is supply nozzle; 2 is housing cover; 3 is accelerator; 4 are acceleration ribs; 5 is armor; 6 is electric motor; 7 is Vbelt transmission Principle of laboratory crusher Before starting operation, the accelerator operation installed in the crusher is rotated at a nominal or lower speedExperimental study of crushing process of the crushed stoneIJCRT22A6006 International Journal of Creative Research Thoughts (IJCRT) ijcrt 48a 3 DESIGN AND IMPLEMENTATION 31 Block Diagram Fig 31 Schematic block diagram of the EPlastic Crusher 32 Methodology Fig 32 The flow of the operation EPlastic Crusher 33 SIMULATION Simulation tests were performed using the software, Design And Development of an EPlastic Crusher

Design and Fabrication of Can Crusher IJIRSET

International Journal Of Modern Engineering Research (IJMER), Vol 3, Issue1, 2013 PP518522 ISSN: 22496645 2 Mr Che Mohd Akhairil Akasyah B Che Anuar Faculty of Mechanical Engineering in University Malaysia Pahang in the year Nov2008 in his project report entitled “Development of the Can Crusher Machine” 3and development, the invented crusher design concepts present the respective invention without considering sustainability concerns regarding the three pillars; environment, economic and social impact throughout the product life cycle This study shows the potential selection of crusher design concepts as the most sustainable productSELECTION OF CRUSHER DESIGN CONCEPTS AS A SUSTAINABLE Design and Fabrication of Can Crusher M P Nawathe1 Ghanshyam Ingle2 Pranjali Kharode3 Sneha Pradhan4 Dnyaneshwar Rathod5 IJSRD International Journal for Scientific Research Development Vol 6, Issue 01, 2018 ISSN (online): 23210613 Author: ijsrd Subject: Design and Fabrication of Can CrusherDesign and Fabrication of Can Crusher IJSRD

Types of Crushers: What You Need to Know Machinery Partner

There are lots of different kinds of crushers from jaw crushers to impactors and cone crushers Crushing is an versatile process and the kind of crusher you need depends on the 'stage' of crushing The three main stages of crushing are primary, secondary, and tertiary all of which have their own unique benefits