عنا

مرحبا هل يمكنني مساعدتك؟

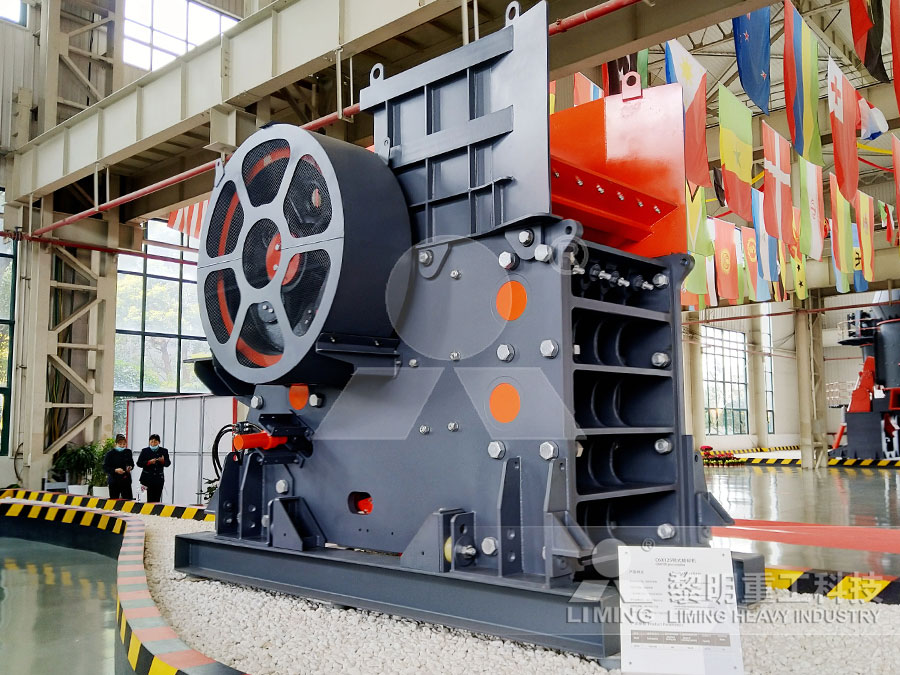

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

Function Of Roller Mill Rolls

2022-06-14T22:06:52+00:00

Function and arrangement of pinch rolls – Hangji Rolling Mill

The main function of the pinch roller is to pinch the wire coming out of the watercooling section and smoothly send it into the spinning machine In order to meet the requirements of highspeed pinch, the design of pinch roller is constantly improvedTo roll material in a rolling mill the rolls are driven in 4highmills for flat products normally the work rolls but in some exceptions the backup rolls and the torque has to be A Basic Understanding of the Mechanics of Rolling Mill Rolls2021年2月16日 Today's roller mills are an essential part of the American food production chain Modern flour production depends on the use of grain roller mills to reduce wheat berries into flour In addition, roller mills are Roller Mills: What They Are Why They're Great

Forged Steel Roll Back Up Roll For Rolling Mill

2020年2月27日 The forged back up roll is a mill roll that supports the work roll and intermediate roll for the purpose of avoiding deflection of the work roll and affecting on the yield and quality of the plate and strip rolling mill 2022年11月30日 Roller mill is a form of compression mill that uses a single, double, or triple cylindrical heavy wheel mounted horizontally and rotated about their long axis either in opposing pairs or against flat Roller Mill: Components, Designs, Uses, 2023年9月6日 The main functions of flour mill grinding rolls are: Crushing action The grinding rolls crush the grains between them and break them into flour The roll surface is News Composition and main functions of flour mill rollers

Types of Rollers and How They Are Used MISUMI

2021年2月16日 6 min read Rollers are widely used components that serve the simple yet surprisingly diverse functions of facilitating and processing material and product movements in manufacturing and/or industrial The Raymond® Roller Mill is an airswept vertical ringroll mill with an integral classification system that simultaneously dries, pulverizes and classifies a number of different types of Raymond® Roller Mill airswept vertical ringroll Schenck 16 小时之前 A rolling mill is a complex machine having two or more working rollers, supporting rollers, roll stands, drive motor, reducing gear, flywheel, coupling gear etc Rolling of Metals: Process and Principles (With Diagram)

Three Roll Mill Franli Machine

Three Roll Mill, their gap of the roller is controlled by adjustable wheels TRS three roller mill is an updated type based on S triple roll 1TRS machine transfer gears that soak in oil (oil box) Keeping longer life of the 2007年1月1日 Breakage of wheat kernels during roller milling has been modelled in terms of the distribution of kernel characteristics (hardness, size, moisture) and roller mill operation (roll gap, disposition) A correction function to account for the effects of pearling kernels prior to breakage has been demonstratedChapter 7 Roller Milling of Wheat ScienceDirectA coupled vibration model of hot rolling mill rolls under multiple nonlinear effects is established by considering the nonlinear spring force produced by the hydraulic cylinder, the nonlinear friction between the work rolls, the Coupled Vibration Behavior of Hot Rolling Mill

Vibration Characteristics of Hot Rolling Mill Rolls Based on

2021年5月26日 Based on the analysis of the influence of roll vibration on the elastoplastic deformation state of a workpiece in a rolling process, a dynamic rolling force model with the hysteresis effect is established Taking the rolling parameters of a 1780 mm hot rolling mill as an example, we analyzed the hysteresis between the dynamic rolling force and the roll 2018年8月22日 Lab Two Roll Mill DW5110 is a open type rubber refining machine Rubber factory used to make plastic rubber, mixed rubber or hot refining, out of a type of rubber roller exposed machine The main working parts are two hollow rollers or drilling rollers rotating in opposite direction The device is called the front roller on the operator sideTwo Roll Mill Structure and Classification FYI TesterThe Raymond® Roller Mill is an airswept vertical ringroll mill with an integral classification system that simultaneously dries, pulverizes and classifies a number of different types of products including limestone, clay, minerals and others From a feed ranging in size from approximately ½ 2in / 1050mm, the roller mill can produce Raymond® Roller Mill airswept vertical ringroll Schenck

Roller Mill: Components, Designs, Uses, Advantages and

2022年11月30日 Advantages of Roller Mills 1 Produce more uniform, fewer fines, and oversized particles when it comes to product quality 2 Generates less heat (0 – 3 0 C) unlike hammer mill that generates up to 10 0 C 3 Less moisture loss 4 Better work environment due to low machine noises level2022年5月24日 1 Two High Rolling Mills It contains two heavy rolls fixed one over the other The rolls are supported in bearing housed in sturdy upright frames (called stands) which are grouted to the rolling mill floor The vertical gap between the roll is adjustable The rolls rotate in opposite directions and are driven by electrical motorsRolling Mills: 6 Different Types of Rolling Mills [Images PDF]Failure Analysis of Rollers in mill stand using Failure mode Effect Analysis depth The oxide layer on the roll surface grows as a function of the roll surface temperature when 5 Barrel 6 6 4 144 leaving the roll bite and time of exposure to air at Edge elevated temperature This oxide layer is submitted to alternating shear stresses due to (PDF) Failure Analysis of Rollers in mill stand using Failure

Rolling Mills: What They Are How They Work What is a Rolling Mill?

2021年4月19日 At its most basic principle, a rolling mill is a machine that reduces the thickness of a metal without sacrificing any of the material – meaning material is always displaced and never lost By design and function, rolling mills do not generate scrap The process of rolling affects the materials at a metallurgical level and the desired The main function of the pinch roller is to pinch the wire coming out of the watercooling section and smoothly send it into the spinning machine In order to meet the requirements of highspeed pinch, the design of pinch roller is constantly improved The current mainstream design is integrated parallel transmission, horizontal cantilever Function and arrangement of pinch rolls – Hangji Rolling MillIn a roller mill the practice centres around separating the three components of a wheat seed – the white endosperm, the outer bran layers and the wheat germ Eventually all the endosperm particles will pass through a series of smooth reduction rolls for final milling into white flour In a typical mill, there may be up to 4 break rollers The milling process UK Flour Millers

MF2048 Hammermills and Roller Mills Kansas State

Roller mills accomplish size reduction through a combination of forces and design features If the rolls rotate at the same speed, compression is the primary force used If the rolls rotate at different speeds, shearing Hammermills and Roller Mills Kim Koch Northern Crops Institute North Dakota State University Fargo, NDRolling is an important function of the steel industry It’s a steel fabrication process involving passing the metal through a pair of rollers There are two main types of rolling process: Flat rolling – the finished product is a sheet Profile rolling – the finished product is a bar or rod The process always starts with hot rollingCold Rolling – Process Overview Matmatch2009年1月1日 Abstract Based on screening analysis, laser size analysis, grindability and rigidity tests of samples collected on line from a cement and a power plant, a simulation of the grinding process in vertical roller mills was carried out The simulation calculation used a breakage function, B The results indicate that the breakage function, B, and Grinding process within vertical roller mills: experiment and

On Predicting Roller Milling Performance IV: Effect of Roll

2003年1月1日 Different grinding methods, including the use of roller mills, hammer mills, multicracker and multistage grinding were reviewed Roller milling tends to produce a more uniform particle size distribution (PSD) and consumes less energy, whilst hammer mills have a greater grinding capacity and a higher reduction ratio compared to roller mill2021年4月1日 Considering the nonlinear stiffness constraint action from the hydraulic cylinder in the fourhigh rolling mill process, the vertical vibration dynamic model with two degrees of freedom is established The nonlinear vertical vibration equation of roll system contained the nonlinear stiffness of the hydraulic cylinder is established on the basis of Research on vibration characteristics of mill rolls based on Making “digital twins” for rolling processes and mill equipment should begin with the development of mathematical models of the deformation zone The deformation zone of twohigh flat mill rolling have been studied in detail, relevant models are available in many academic papers However, the same cannot be said about the most complex Calculating Power Parameters of Rolling Mill Based on

Rice Mills Functioning Guide Hindustan Group

Paddy Dehusking This paddy consists of rice covered by the protection layer known as Husk After cutting paddy from the field, it is cleaned to remove dust sticking on it And then this paddy is taken to rice mill for final processing Many years back two iron rolls rotating at different speeds were used to remove the huskAs a professional China Pinch Roll manufacturer, we are equipped with a famous factory and plant and engineers with decades experience, as well as providing with CCM Machine, TMT Rebar Mill, Wire Rod Mill, finishing mill, rolling mill stand, hot rolling mill, section rolling mill, etcfor sale, welcome to visit and check the process and layout with Xi’an Hani Tech Pinch Roll Pinch Roll for Steel Rolling Mill in China Hani 2016年6月26日 In order to study the hot Compact Strip Production (CSP), fourhigh mill vibration characteristics, and vibration suppression method, the roller system structure stability was analyzed and calculated at first in Impact Analysis of Roller System Stability for Four

Axial Force Analysis and Roll Contour

In order to analyze the influence of technical parameters on work roll axial force of fourhigh continuous variable crown (CVC) mill, the deformation analyzing model with top roll system and strip was established based on 2018年12月21日 The perforated Roller reduces reabsorption continuously by removing the juice under pressure at the perforation points The Juice removal is extra from the juice removed in normal function of Sugar Mill Rollers jagatmachinery2013年5月30日 Fig 4 Roll configurations in rolling mills Twohigh mill roll configuration – This is the most commonly used rolling mill configuration In this configuration, there are two horizontally mounted rolls The rolling mill motor drives either both rolls (top and bottom) or only one roll (normally the bottom roll) with the top roll rotating due to the friction between Basics of Rolling and Rolling Mills – IspatGuru

Best practices for safe and efficient three roll milling Mixers

2023年11月3日 Do not run the mill dry When product has almost run through, open the rolls and disengage the apron Do not wear loose articles of clothing or any accessories that can get caught in the rolls Roll journals are equipped with ball or roller bearings It is good practice to lubricate the bearings on a monthly basis2015年12月10日 Tab 4 Types of rolls for section mills : Type of roll: Surface hardness (Deg Shore) Forged steel rolls, Roughing, Intermediate and Finishing rolls: 2430: Cast steel, 04 to 09 % C, Roughing rolls: 2836: Pearlitic grain rolls, Strong, tough and resistant to fire cracking, Roughing, Intermediate and Finishing rolls: 3038Rolling mill Rolls and Roll Shop – IspatGuru2021年4月16日 In one of his drawings, Da Vinci designed a rolling mill featuring a pair of rollers With that said, modernday rolling mills didn’t emerge until the 19th century In 1820, Bedlington Ironworks produced one of the world’s first railbased rolling mills Railbased rolling mills are those that are designed to create long and narrow beams or How Rolling Mills Work in Steelmaking OneMonroe

eFeedLink Mobile

The earliest roller mills used in the feed milling were abandoned flour milling roll stands, used primarily to produce coarse granulations of friable materials Over time, roller mills have been used to perform a wide variety of tasks related to the production of animal feeds Roller mills are commonly referred to by the type of service they 2019年4月4日 10 On the head breaks (B1, B2, and B3), to cut open the wheat kernel and scrape the endosperm away from the bran skin and germ in as course sizes as possible and at the same time leaving the bran Functions of break system in flour milling process LinkedIn2020年5月25日 Normal ceramic roll mill jar From 10L to 15L 304 Stainless steel roll mill jar From 05L to 20L Alumina ceramic (Corundum) roll mill jar From 05L to 10L Nylon roll mill jar From 05L to 20L Polyurethane roll mill jar From 05L to 20L PTFE/Teflon roll mill jar From 05L to 20L Tungsten carbide roll mill jar From 250ml to 3LLab Jar Mill labmills

Processes Free FullText Comprehensive

2021年10月15日 The development of convenience foods by incorporating nutrientrich pulses such as peas and lentils will tremendously alter the future of pulse and cereal industries However, these pulses should be 2020年7月3日 DC Pinch Rolls are made available in two versions contileaver type and pneumatic up to 360mm crs We hold expertise in providing AC pinch roll comprising contileaver type mechanical up to 400mm crs Pinch rolls featuring use of sensors that allows precision breaking up of speed of hot flowing materialPinch Roll Manufacturers Rolling Mill Machinery16 小时之前 A rolling mill is a complex machine having two or more working rollers, supporting rollers, roll stands, drive motor, reducing gear, flywheel, coupling gear etc Rollers may be plain or grooved depends upon the shape of rolled product The metal changes its shape gradually during the period in which it is in contact with the two rollersRolling of Metals: Process and Principles (With Diagram)

Mixing mills DEGUMASCHÜTZ GmbH

2023年11月3日 Mixing mills Mixing mills (also rolling mills) are used for the manufacture of rubber compounds A rubber base material is mixed with several additives, such as fillers, softeners, processing aids and colourants here The two rolls of the rolling mill rotate in the opposite direction For the purpose of mixing, one roll runs faster than the Contact us today to discuss your application in detail with one of our experienced sales engineers Call (314) 6213348, us at info@williamscrusher or locate an agent near you Williams Patent Crusher is an industryleading roller mill manufacturer Learn about our vertical roller mills, centrifugal roller mills and moreIndustrial Roller Mill Roller Mill Manufacturer Williams 2011年9月14日 The crown effects of both mills due to incoming crowns, roll crowns, roll bending, roll shifting are calculated to reveal the linear crown control characteristics of the mill Roll shifting (PDF) A JOURNEY TO OPTIMAL ROLLING MILL DESIGN

Chapter 7 Roller Milling of Wheat Request PDF

2007年12月31日 Roller mill technology, introduced in the US in Minneapolis, Minnesota in 1880, produced a highextraction, pure white flour, largely devoid of micronutrients, which constituted the second 2016年1月1日 The factor for roll speed, k, was evaluated experimentally and is a function of roll speed, ν P, according to the polynomial equation (619) k = C 1 ν P 2 + C 2 ν P + C 3 where C 1 –C 3 are material constants Equation (619) is evaluated experimentally The specific throughput rate can then be computed by combining Equations (618) and (6 Roll Crushers ScienceDirectThree Roll Mill, their gap of the roller is controlled by adjustable wheels TRS three roller mill is an updated type based on S triple roll 1TRS machine transfer gears that soak in oil (oil box) Keeping longer life of the Three Roll Mill Franli Machine

Chapter 7 Roller Milling of Wheat ScienceDirect

2007年1月1日 Breakage of wheat kernels during roller milling has been modelled in terms of the distribution of kernel characteristics (hardness, size, moisture) and roller mill operation (roll gap, disposition) A correction function to account for the effects of pearling kernels prior to breakage has been demonstratedA coupled vibration model of hot rolling mill rolls under multiple nonlinear effects is established by considering the nonlinear spring force produced by the hydraulic cylinder, the nonlinear friction between the work rolls, the Coupled Vibration Behavior of Hot Rolling Mill 2021年5月26日 Based on the analysis of the influence of roll vibration on the elastoplastic deformation state of a workpiece in a rolling process, a dynamic rolling force model with the hysteresis effect is established Taking the rolling parameters of a 1780 mm hot rolling mill as an example, we analyzed the hysteresis between the dynamic rolling force and the roll Vibration Characteristics of Hot Rolling Mill Rolls Based on

Two Roll Mill Structure and Classification FYI Tester

2018年8月22日 Lab Two Roll Mill DW5110 is a open type rubber refining machine Rubber factory used to make plastic rubber, mixed rubber or hot refining, out of a type of rubber roller exposed machine The main working parts are two hollow rollers or drilling rollers rotating in opposite direction The device is called the front roller on the operator sideThe Raymond® Roller Mill is an airswept vertical ringroll mill with an integral classification system that simultaneously dries, pulverizes and classifies a number of different types of products including limestone, clay, minerals and others From a feed ranging in size from approximately ½ 2in / 1050mm, the roller mill can produce Raymond® Roller Mill airswept vertical ringroll Schenck 2022年11月30日 Advantages of Roller Mills 1 Produce more uniform, fewer fines, and oversized particles when it comes to product quality 2 Generates less heat (0 – 3 0 C) unlike hammer mill that generates up to 10 0 C 3 Less moisture loss 4 Better work environment due to low machine noises levelRoller Mill: Components, Designs, Uses, Advantages and

Rolling Mills: 6 Different Types of Rolling Mills [Images PDF]

2022年5月24日 1 Two High Rolling Mills It contains two heavy rolls fixed one over the other The rolls are supported in bearing housed in sturdy upright frames (called stands) which are grouted to the rolling mill floor The vertical gap between the roll is adjustable The rolls rotate in opposite directions and are driven by electrical motorsRolling is an important steel production process Productivity and quality improvements in metal rolling are possible by paying a detailed attention to the various roll failure modesA proper understanding of the causes of roll failure modes is usually complex and depends on the metallurgical quality of rolls, improper mill usage practices and abnormal rolling (PDF) Failure Analysis of Rollers in mill stand using Failure 2021年4月19日 At its most basic principle, a rolling mill is a machine that reduces the thickness of a metal without sacrificing any of the material – meaning material is always displaced and never lost By design and function, rolling mills do not generate scrap The process of rolling affects the materials at a metallurgical level and the desired Rolling Mills: What They Are How They Work What is a Rolling Mill?