عنا

مرحبا هل يمكنني مساعدتك؟

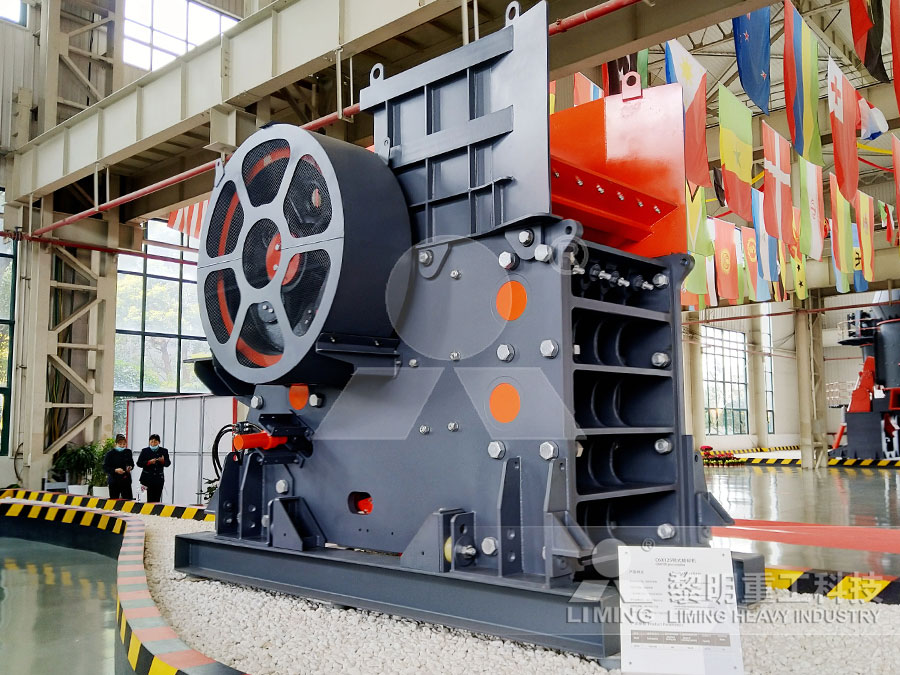

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

definition of critical speed of Vertical mill

2022-12-20T01:12:21+00:00

definition of critical speed of Vertical mill cbshetwestpunt

The critical speed is the minimum speed that an object must have at the top position of a vertical circular path in order to remain in circular motion The centripetal force acting on Mill Speed Critical Speed Paul O Abbe,Critical Speed (left) is the speed at which the outer This type of pulverizer is usually one of two types: ball and race and roll and race The speed of the grinding section of these mills is usually between 75 and 225 rpm Mediumspeed Mill Speed an overview ScienceDirect Topics2015年10月15日 Mill Critical Speed Calculation Effect of Mill Speed on the Energy Input In this experiment the overall motion of the assembly of 62 Mill Critical Speed Calculation 911 Metallurgist

: Mill Critical Speed Determination

The "Critical Speed" for a grinding mill is defined as the rotational speed where centrifugal forces equal gravitational forces at the mill shell's inside surface This is the rotational 2015年6月19日 Use our online formula The mill speed is typically defined as the percent of the Theoretical Critical Speed, often abbreviated as %Cs The Theoretical Critical Speed Ball Mill Critical Speed 911 Metallurgist2017年4月24日 the operating speed of a ball mill should be the critical, Know More Mobilith Shc 100 Buy Synthetic Grease Product on the operating speed of a ball mill Critical Speed Of Vertical Mill bmuellerelektrotechnik

Mill Critical Speed Formula Derivation 911 Metallurgist

2023年10月27日 The formula to calculate critical speed is given below N c = 42305 /sqt(Dd) N c = critical speed of the mill D = mill diameter specified in meters d = The critical speed n (rpm) when the balls are attached to the wall due to centrifugation: Sign in to download fullsize image Figure 27 Displacement of balls in mill where D m is the Ball Mill an overview ScienceDirect Topics2019年12月9日 Speed rate refers to the ratio of the speed of the mill to the critical speed, where the critical speed is n c = 30 / R In practice, the speed rate of the SAG mill is generally 65% to 80% Therefore, in the Optimal Speed Control for a SemiAutogenous

Grinding Mills 911 Metallurgist

1 天前 The graph below will be helpful in determining percentage of critical speed when internal mill diameter and RPM are known A Grinding Mill is a revolving cylinder loaded to approximately onehalf its volume with steel 2020年1月24日 Speed: Vertical mills are accurate but can be slower than a horizontal milling machine when highvolume production is required In terms of drawbacks, the most critical one is the higher costs associated Horizontal vs Vertical Milling and Turning: What However, after reaching a critical speed, the mill charge clings to the inside perimeter of the mill Under this conditions, the grinding rate is significant reduced or stopped All mills must operate less than Critical Speed; At AMIT 135: Lesson 7 Ball Mills Circuits – Mining

Critical rotation speed for ballmilling ScienceDirect

1999年8月3日 2 Experiment To examine the dependence of critical rotation speed on ballcontaining fraction, we measured critical speeds at various ballcontaining fractions from 03 to 095 stepped by 005 Since at lower fraction than 03 we could not observe the centrifugal motion, we chose this fraction range A jar of ballmill consists of a cylinder 2022年5月1日 The critical speed of a rotor is the same whether it is vertical or horizontal Critical speed calculation is fairly straightforward for gas/air turbines, compressors, fans and blower units, but is much more difficult for units that involve liquids Critical speed calculations for air and gas units are normally correct within a few percentThe Importance of Critical Speed Pumps Systems2022年8月31日 After determining the correct feed and speed, the table is moved along the Xaxis into the rotating cutter to remove material 3 Side Milling End mills are the standard vertical mill cutting tools, producing a vertical, horizontal, or angular flat surface You can hold end mills in standard holders or colletsThe 15 Most Common Milling Machine Operations

(PDF) Increase productivity of vertical roller mill

2021年1月29日 FlyAsh Blaine: Increase fly Ash Blaine from 290 to 320 Flyash is a major supply for any cement plant now a days because every producer wants to produce more PPC than OPC due to profitability 2015年3月15日 Introduction The TowerMill® was developed in Japan in the 1950s, by the Tower Mill Kubota Corporation, for applications in fine and ultrafine grinding, and it was the first vertical mill used in the mineral industry (Stief et al, 1987)The Vertimill™, manufactured by has basically the same principle of operation and was introduced in the 1990’s Vertical Agitated Media Mill scaleup and simulation2022年2月1日 This paper presents a numerical study on the particle conveying in a feed screw section of vertical rice mill based on the discrete element method The effects of key parameters, including rotational speed, height and type of feed inlet, are investigated by a series of controlled numerical experimentsDEM investigation of particle flow in a vertical rice mill:

Optimal Speed Control for a SemiAutogenous

2019年12月9日 Speed rate refers to the ratio of the speed of the mill to the critical speed, where the critical speed is n c = 30 / R In practice, the speed rate of the SAG mill is generally 65% to 80% Therefore, in the 22 May, 2019 The ball mill consists of a metal cylinder and a ball The working principle is that when the cylinder is rotated, the grinding body (ball) and the object to be polished (material) installed in the cylinder are rotated by the cylinder under the action of friction and centrifugal force At a certain height, it will automatically The working principle of ball mill Meetyou CarbideThe key control parameter of continuous casting is matching the flow of liquid steel into the mold with the withdrawal speed of the strand out of the mold The control of flow rates is accomplished by the tundish, a small, Steel Continuous Casting, Alloying, Heat

Mill Speed an overview ScienceDirect Topics

Autogenous and SemiAutogenous Mills In Mineral Processing Design and Operations (Second Edition), 2016 934 Mill Speed During normal operation the mill speed tends to vary with mill charge According to available literature, the operating speeds of AG mills are much higher than conventional tumbling mills and are in the range of 80–85% of the Critical speed (n k) is the rotational speed at which acting dynamic forces cause a machine component (eg shaft, rotor) to vibrate at its natural frequency (also referred to as intrinsic frequency, f i) and can even result in resonant vibrations throughout the entire machine and pump setThis effect has the potential to damage fast rotating machinery but can be Critical speed KSB2017年4月1日 Vertical roller mills (VRM) have found applications mostly in cement grinding operations where they were used in raw meal and finish grinding stages and in power plants for coal grinding The mill combines crushing, grinding, classification and if necessary drying operations in one unit and enables to decrease number of equipment in grinding Operational parameters affecting the vertical roller mill

Vertical Mills VMC Haas Machines Haas Automation

2023年11月3日 Get a quick look at the complete vertical mill lineup Haas has to offer Our vertical mills provide high performance machining for a magnitude of applications No matter your part, industry, or needs, there’s a Haas vertical machine perfect for your shop HighSpeed, LeanStyle Machining Centers CNY ONLY Toolroom Mills 40 Taper; 3/4/5 2017年10月24日 Critical speed of a tube mill is that speed of rotation at which the centrifugal power neutralizes the force of gravity which influences the grinding balls, the grinding balls don't fall and therefore don't perform grinding work To make the definition easier, critical speed is the rotational speed in rpm of the millCritical Speed PDF Mill (Grinding) Speed Scribd2015年3月15日 The vertical mill was operated with a screw speed of 87 The critical speed N c can be calculated according to Eq (14) (14) N c = 42, 306 D md max where N c is the critical speed (rpm); D m is the internal mill diameter (m); d max is the maximum ball diameter (m) 334 Batch grinding testsVertical Agitated Media Mill scaleup and simulation

Vertical vs Horizontal Milling Machines Fusion 360 Blog

2021年2月1日 Turret mills provide two cutting methods in the vertical (Z) direction: by raising or lowering the quill and by moving the knee The table only moves perpendicular to the spindle’s axis in vertical bed mills, while the spindle itself moves parallel to its own axis Horizontal Milling Machines In horizontal mills, the cutters are mounted on a Critical Speed Critical speed is defined as the point at which the centrifugal force applied to the grinding mill charge is equal to the force of gravity At critical speed, the grinding mill charge clings to the mill inner surface and Ball Mill (Ball Mills Explained) saVRee saVRee2020年1月29日 The rotational speed of the mill was kept at 85% of the critical speed The sample ore charge, Q, was such that the ore sample completely filled the voids or interstitial spaces between the balls, meaning that the mass of the charge varied with the ball diameters [4] The residence time was material dependent and thusabeya and ototi, J ateria Sci ng , Journal of Material

Wind Turbine Speed TurbineGenerator

2023年7月11日 Wind Turbine Tip Speed Ratio (TSR) is the speed of the tip divided by the speed of the wind For example if the tip speed is 120 miles/hour and the wind speed is 20 miles/hour than the TSR = 120 / 20 2015年6月19日 The approximate horsepower HP of a mill can be calculated from the following equation: HP = (W) (C) (Sin a) (2π) (N)/ 33000 where: W = weight of charge C = distance of centre of gravity or charge from centre of mill in feet a = dynamic angle of repose of the charge N = mill speed in RPM HP = A x B x C x L WhereBall Mill Design/Power Calculation 911 Metallurgist2021年2月3日 the highspeed motor to ensure the stability and secure operation The critical speed analysis can enable the identification of sensitivity level of the rotor system to each design parameter This will allow designers to adjust the rotor critical speeds quickly and easily Belmans et al [3] studied the critical speedEffective approach for calculating critical speeds of

Ball Mill Principle, Application, Uses, Critical Speed, Diagram

2023年2月25日 The critical speed of a ball mill can affect the performance and product quality of the mill If the speed is too slow, the grinding balls will not be lifted and will not effectively grind the material On the other hand, if the speed is too fast, the grinding balls will be thrown against the outer wall of the mill, resulting in ineffective 16 小时之前 The process of shaping metals into semifinished or finished forms by passing between rollers is called rolling Rolling is the most widely used metal forming process It is employed to convert metal ingots to simple stock members like blooms, billets, slabs, sheets, plates, strips etc In rolling, the metal is plastically deformed by passing Rolling of Metals: Process and Principles (With Diagram)2022年5月9日 The raw materials were mixed in a certain proportion and fed into a vertical roller mill (LOESCHE mill) The raw vertical roller mill has four rollers, 3000 KW main drive, 48 m table diameter, 2 Modeling of energy consumption factors for an industrial

Optimal Speed Control for a SemiAutogenous

2020年2月18日 Speed rate refers to the ratio of the speed of the mill to the critical speed, where the critical speed is n c = 30 / R In practice, the speed rate of the SAG mill is generally 65% to 80% Therefore, in the 2023年10月18日 The critical speed of a ball mill is the speed at which the contained balls start to revolve along the inside walls The balls inside a ball mill will remain motionless at the bottom where they will have little to no Mills: What are they? How are Mills used?2021年1月19日 Types of Milling Machines Some of the main types of milling machines are as under: 1 Horizontal or Plain Milling Machine Plain milling machines are more robust than hand millers Plain milling 15 Different Types of Milling Machines

How can I determine the best RPM for Dry Ball Milling machine in order

2016年10月14日 Critical speed (in rpm) = 423/sqrt(D d) with D the diameter of the mill in meters and d the diameter of the largest grinding ball you will use for experiment (also expressed in meters)2016年11月23日 issues and therefore supports commercial applications of this vertical stirred mill Stirred media mills are influenced by a great number of operating variables A study was conducted to understand the influence of mill speed, feed particle size and, slurry density and rheology on the VXPmill performanceSCALEUP AND OPERATIONS OF A VERTICAL STIRRED 2022年5月31日 An increase in rotation from 60 to 100 rpm (about a 666% increase) leads to a 251% reduction in crushing rate The throughput increases by an average speed of 0026 kg/s for each rotation speed increment of 10 rpm The analyzed results show that the rotation speed has a significant effect on both the crushing rate and throughputAnalysis of vertical roller mill performance with changes in

Horizontal vs Vertical Milling: What Are Their Differences

2022年5月13日 A vertical mill offers greater visibility to the users and even has lower programming requirements than its horizontal counterparts Lowvolume production: Because of their relative simplicity and lower costs, vertical mills are the method of choice for low quantities and quick jobs Moreover, you won’t even have to spend too much time on 2022年7月26日 The critical speed N c of a shaft is simply Where m = the mass of the shaft assumed concentrated at single point k is the stiffness of the shaft to traverse vibrations For a horizontal shaft this can be expressed as Where y = the static deflection at the location of the concentrated mass Symbols m = Mass (kg) N c = critical speed (rev/s Drive Shafts Critical Speed Roy Mech1 天前 The graph below will be helpful in determining percentage of critical speed when internal mill diameter and RPM are known A Grinding Mill is a revolving cylinder loaded to approximately onehalf its volume with steel Grinding Mills 911 Metallurgist

Horizontal vs Vertical Milling and Turning: What

2020年1月24日 Speed: Vertical mills are accurate but can be slower than a horizontal milling machine when highvolume production is required In terms of drawbacks, the most critical one is the higher costs associated However, after reaching a critical speed, the mill charge clings to the inside perimeter of the mill Under this conditions, the grinding rate is significant reduced or stopped All mills must operate less than Critical Speed; At AMIT 135: Lesson 7 Ball Mills Circuits – Mining 1999年8月3日 2 Experiment To examine the dependence of critical rotation speed on ballcontaining fraction, we measured critical speeds at various ballcontaining fractions from 03 to 095 stepped by 005 Since at lower fraction than 03 we could not observe the centrifugal motion, we chose this fraction range A jar of ballmill consists of a cylinder Critical rotation speed for ballmilling ScienceDirect

The Importance of Critical Speed Pumps Systems

2022年5月1日 The critical speed of a rotor is the same whether it is vertical or horizontal Critical speed calculation is fairly straightforward for gas/air turbines, compressors, fans and blower units, but is much more difficult for units that involve liquids Critical speed calculations for air and gas units are normally correct within a few percent2022年8月31日 After determining the correct feed and speed, the table is moved along the Xaxis into the rotating cutter to remove material 3 Side Milling End mills are the standard vertical mill cutting tools, producing a vertical, horizontal, or angular flat surface You can hold end mills in standard holders or colletsThe 15 Most Common Milling Machine Operations 2021年1月29日 FlyAsh Blaine: Increase fly Ash Blaine from 290 to 320 Flyash is a major supply for any cement plant now a days because every producer wants to produce more PPC than OPC due to profitability (PDF) Increase productivity of vertical roller mill

Vertical Agitated Media Mill scaleup and simulation

2015年3月15日 Introduction The TowerMill® was developed in Japan in the 1950s, by the Tower Mill Kubota Corporation, for applications in fine and ultrafine grinding, and it was the first vertical mill used in the mineral industry (Stief et al, 1987)The Vertimill™, manufactured by has basically the same principle of operation and was introduced in the 1990’s 2022年2月1日 This paper presents a numerical study on the particle conveying in a feed screw section of vertical rice mill based on the discrete element method The effects of key parameters, including rotational speed, height and type of feed inlet, are investigated by a series of controlled numerical experimentsDEM investigation of particle flow in a vertical rice mill: