عنا

مرحبا هل يمكنني مساعدتك؟

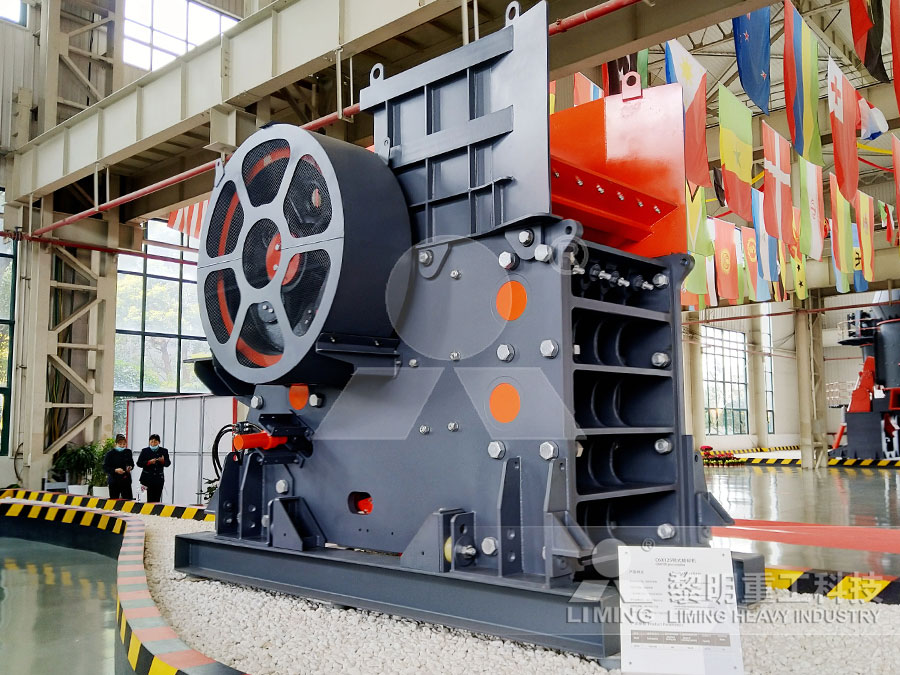

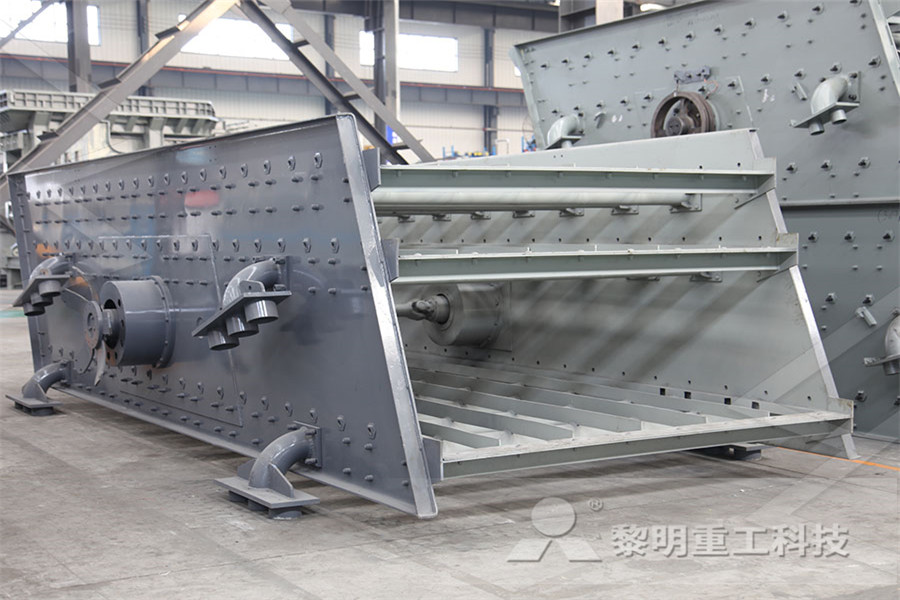

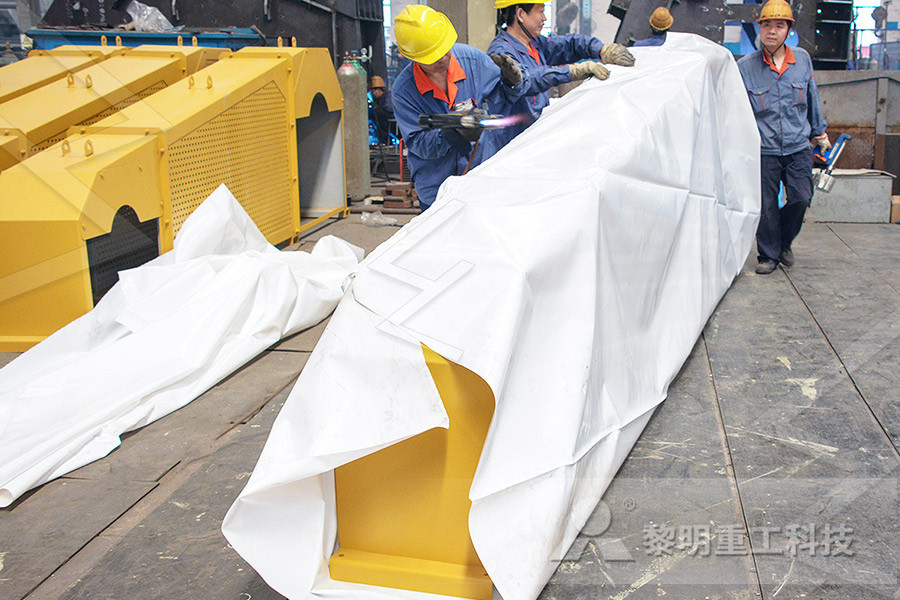

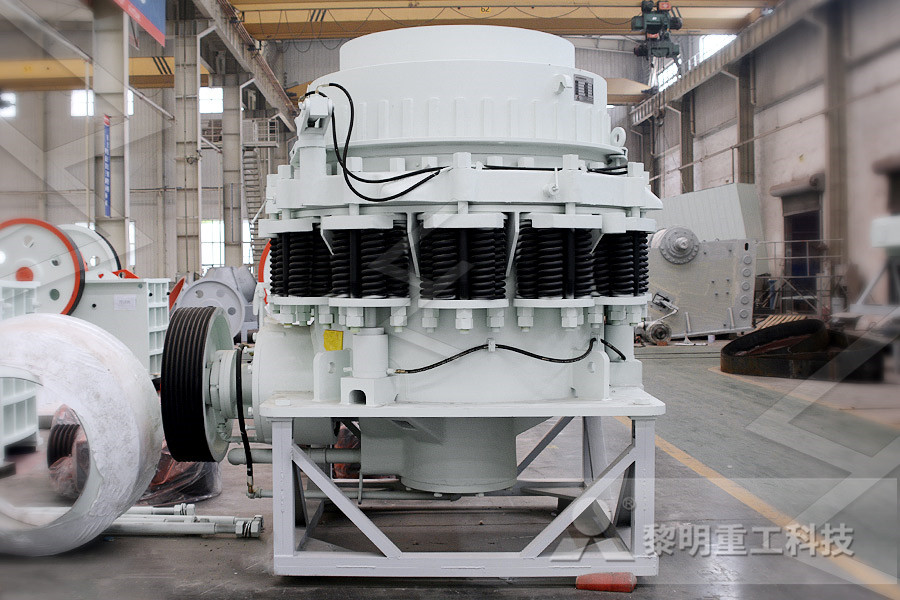

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

procedure for installation of a jaw crusher pdf

2023-01-01T01:01:00+00:00

Jaw Crushers JW Series

2021年2月1日 Simple maintenance Jawfaces are retained by a mechanical wedge locking system removing the need to access bolts behind the cast front end frame of the crusher 2021年8月20日 Following is the procedure introduced by Luoyang Dahua: 1 Often check the discharging situation, if found it is blocked, should clean in time 2 Adjust the opening Operation Procedure of Jaw Crusher Luoyang Dahua2018年12月26日 3 Construction, Working and Maintenance of Crushers for Crushing Bulk Materials practicalmaintenance Crushers for Bulk Materials Crushers and Construction Working and Maintenance of Crushers for

(PDF) DESIGN AND OPERATIONS CHALLENGES OF

2017年6月30日 Determination of the optimal angle of inclination of the toggle plate, development of jaws with varying wear rate along the crushing chamber, and development of comminution energy models that take2021年7月28日 material (aggregate) to different specced sizes Load the crusher with an excavator or loader, process it and screen the end product to be stockpiled SAFE WORK PROCEDURE FOR Crushing Operations Pinned and bolted, nonwelded frame construction Save time and costs Minimize onsite engineering Install easily Modular design enables easy installation C Series jaw crushers are modular for quick, easy ® C Series™ jaw crushers

The Most Practical Jaw Crusher Repair and

2023年2月15日 The Most Practical Jaw Crusher Repair and Maintenance Manual Author : Jordan Last Updated : Feb 15, 2023 Just like other stone crusher machines, jaw crusher also needs a regular repair and 2023年10月12日 Written instructions should be issued to plant operators This should detail the procedures to follow in the event of a crusher stalling These instructions should HSE Quarries Safe operation and use of mobile jaw crushers英语网站资料 Contribute to boy/en development by creating an account on GitHuben/procedure for installation of a jaw crusher pdfmd at main

® C Series™ jaw crushers

The core of ® C Series™ jaw crusher is a pinned and bolted, nonwelded frame construction that provides excellent fatigue strength All the frame components are casted using an alloy developed inhouse Safe Operating Procedure 1 Before starting, all jaw crusher parts must be fastened installed The tail traction spring is suitable loose, and the engine oil is installed in the swing bolster 2 Jaw rock crusher must test run 2 Jaw Crusher Handbook Stone Crusher PDF JXSC 2018年10月15日 • After a new jaw die installation, rotate the singlepiece jaw dies when 30% of the tooth profile is worn • Rotate a second time when the tooth profile at the bottom of the jaw die is completely worn This procedure allows for good work hardening of the manganese jaw dies, and helps maintain the best nip angle for maximum throughput ® C Series™ jaw parts

SANDVIK JAW CRUSHER SERIES Sandvik Mining and

2020年4月1日 The Sandvik jaw crusher line is designed for the motor sizes listed in RPG and technical specifications This means that for harder materials, the crusher will have to be operated at larger settings to avoid overload of drive and/or motor Using oversized motors will lead to radically shorter crusher life and various mechanical problems2020年7月24日 lifetime of the jaw crusher C Series jaw crushers are modular for quick, easy installation and commissioning in new plants and when replacing old jaw crushers This minimizes onsite engineering and fabrication, saves time, and reduces installation and structural costs The integral motor base reduces space requirements andEngineered for the toughest feed materials ® Technical specifications ® C Series™ jaw crushers C80™ Technical specifications ® C Series™ jaw crushers C106™ Crusher throughput capacity, scalped feed material Capacity 55 75 Closed side setting Crusher throughput capacity, nonscalped feed material Closed side setting 40 mm Mtph Stph Benefits of primary crushing with scalping ® C Series™ jaw crushers Corporation PDF

Below the surface: Setting up an underground primary jaw crusher

2014年4月1日 Jaw crushers are the most common solution in underground applications when the throughput is below 1000 tonnes per hour, depending somewhat on the scalping solutions Above 1000 tph, primary gyratory crushers are an option After the throughput reaches 2000 tph, jaw crushers are very rare, with the exception of a parallel plant layout2022年9月30日 Installation points of the movable jaw Assemble the movable jaw parts in advance After assembling the movable jaw, movable jaw shaft, movable jaw plate, toggle pad, etc on the ground, use a crane or crane to hoist the assembled parts together on the crusher In the rack For sliding bearings, it is necessary to grind and match between the Jaw crushr operate manual: how to install, repair and The inclination is guaranteed to be 02 mm, and the coaxiality is less than 006 mm The installation of the movable jaw is completed 6 Installation of tooth plate Jaw crusher tooth plate is directly used for crushing ore parts Its structure is simple, but because of frequent contact with the ore, tooth plate is the crusher wear quicklyInstallation of Jaw Crusher Skills and Notes JXSC Mine

Crushing Systems

2020年4月15日 and heavier components can allow for process optimization (greater throughput/higher reduction) after installation Maintenance The TS gyratory crusher is distinguished from other gyratory crushers by its revolutionary design which allows major service and maintenance functions to be safely performed颚式研磨仪应用领域 A jaw crusher is always at the very front of the sample preparation chain, precrushing all hard and brittle materials The RETSCH jaw crusher range is primarily used in laboratories and pilot plants under rough conditions but are also suitable for online quality control of raw materials The main fields of Retsch : 产品 : 粉碎设备 : 颚式粉碎仪2016年5月31日 22 Minerals, the world’s leading rock and mineral processing group,has installed over 10 000 jaw crushers since the 1920s Today the C Series is indisputably the world's favourite jaw C series jaw crusher Manual PDF

Site Safety and Safer Aggregate Crushing Operations Agg

2019年9月11日 Tips for keeping a safe crusher include operating the crusher at its appropriate capacity, keeping platforms and areas around machine clean, and ensuring lubrication, flow, temperature, wear and pressure are all monitored Safety is something that can be carried out and planned for daily, monthly and yearly Every day, operators 2023年2月15日 It is inevitable for crusher to get wear because of longtime crushing work, and all you can do is try your best to maximize its service life by regular check and timely maintenance 1 Check whether the tooth peak to tooth valley is match with each other 2 Regularly check whether the bolts and nuts have been tightened so you must ensure that The Most Practical Jaw Crusher Repair and Maintenance Manual2016年2月10日 2 The current system is slow, trying to increase the speed by increasing the gap between jaws of the jaw crusher will result in the jaw crusher producing stones above 30mm diameter which will strain the cone crusher and will result in it breaking down Decreasing the space between jaws will result in the process being extremely slowDesign of a crushing system that improves the crushing

NORDBERG MP SERIES TECHNICAL REFERENCE MANUAL Pdf

Page 161: Crusher Sheave Installation (VBelt Drive) SECTION 4 COUNTERSHAFT, CTRSHAFT BOX SHEAVE ASSEMBLIES 11 Remove the two pullin capscrews and install six M42 x 140 mm LG capscrews for the MP1000 or six M36 x 120 mm LG 50 mm capscrews for the MP800 along with their lockwashers Page 162: Crusher Sheave 2023年1月1日 Isolation of motive power to the crusher and associated plant procedure in Wherever possible any inspection of the crushing cavity of a jaw crusher should be carried out from below the crusher, not from above Remember: RiskAssessmentforSandBlastingpdf RiskAssessmentforSandBlastingpdfRisk Assessment Rock Crusher PDF Industries WasteThe crushing process takes place between a ixed and a moving jaw The moving jaw dies CONE AND GYRATORY are mounted on a pitman that has a recipro CRUSHERS cating motion The jaw dies must be replaced regularly due to wear Both cone and gyratory crushers have an oscil lating shaft(PDF) Crushing and Screening Handbook Academia

(PDF) Selection of a structure of jaw crusher regulator

2021年7月1日 Selection of a s tructure of jaw crusher r egulator A G Nikitin, K V Tagiltsev Galeta , S A Laktionov and A R Fast y kovskii Siberian State Industrial Un iversity, 42 Kirova str, Novokuznetsk 2015年11月6日 39 Item Part No Image 1 DE1007 2 DE6000 3 DE6004 4 DE6015 5 DE6006 DE5024 6 DE6007 7 DE0027 tagout)QH441OperationManual Crusher Works2021年7月28日 material (aggregate) to different specced sizes Load the crusher with an excavator or loader, process it and screen the end product to be stockpiled 2:35 PM SP1202 Page 2 of 10 SAFE WORK PROCEDURE FOR Crusher/Screener Crusher Lock Out 1 Install one or more locks to hold the master switch lever in the OFF position SAFE WORK PROCEDURE FOR Crushing Operations

Site safety and safer aggregate crushing

2020年4月17日 There are many key priorities to consider when ensuring overall site safety and safer crushing operations Safety requires proactive intervention to prevent workplace accidents Each company or site 2023年6月2日 of the crushing process, as well as condition and data monitoring together with many sensors available Crusher automation is easy to install and is provided as complete package including interface to all selected options such as crusher motor starter, hydraulic powerpack, greasing unit and crushers sensorsProven reliability and performance ® C 2021年12月17日 • After a new jaw die installation, rotate the singlepiece jaw dies when 30% of the tooth profile is worn • Rotate a second time when the tooth profile at the bottom of the jaw die is completely worn This procedure allows for good work hardening of the manganese jaw dies, and helps maintain the best nip angle for maximum throughputApplication guide ® C Series™ jaw crusher

C series jaw crushers Wear parts application

2016年2月28日 This procedure will allow for good work hardening of the manganese jaw dies, and maintain the best nip angle for maximum through put One piece jaw die rotation and replacement • After a new jaw die installation, rotate the single piece jaw dies when 30% of the tooth profile is worn • Rotate a second time when the tooth pro2022年11月21日 ing chamber below Jaw gyratory crushers can handle much bigger chunks of material than comparable gyratory crushers of the same mantle diameter Jaw gyratory crushers feature a higher crushing ratio and less tendency to become clogged in the feed zone as a result of bridging Jaw gyratory crusher Weights 1) Type Feed opening Industrial Solutions Gyratory crushers ThyssenKrupp2016年5月7日 Scope of this guidance Mobile crushers are used in a wide range of industries, including quarrying, ore processing and recycling of demolition waste This guidance is for all those with responsibilities for the operation of mobile crushers, including contract managers, supervisory staff and operators of these machines It covers theSafe Operation and Use of Mobile Jaw Crushers PDF Scribd

(PDF) Design and Construction of Rock Crushing Machine

2018年8月7日 jaw crusher machine is made of hardened steel (high carbon steel) It puts the moveable jaw stock in motion (through the mot or, pulley and belt arrangement) that produces the needed force to crush2018年12月1日 In the presented work, a model of the crushing process in a jaw crusher using the Discrete Element Method (MDE) was realized The use of modern software allowed studying in detail the impact of (PDF) Automation experimental studies of grinding process in jaw 2021年7月26日 Fig 25: working principle of a jaw crusher 212 TYPES OF JAW CRUSHERS Typically there are two types of jaw crushers i Single toggle type – This has only one toggle plate It is has less weight and thus cheap ii Double toggle type – This has two toggle plates and can crush materials that are brittle, tough and abrasive Fig 26: CHAPTER 1 10 INTRODUCTION University of Nairobi

Crushing Plant Startup Sequence Procedure

2016年1月26日 Start either cone crusher lube pumps and allow 5 seconds for pressure to build up and oil to be circulated through the crusher Start conveyor #3 (30 second horn will sound)* Start the cone crusher drive 2021年10月28日 crusher operations require wear parts that last longer and are optimized to your specific process Outotec’s jaw dies are engineered to last longer and crush more efficiently, while reducing wear and tear on the crusher The jaw dies are made of manganese steel to secure a long wear life and thereby minimize downtimeOne piece jaws significant reduction in your 2015年11月6日 39 Item Part No Image 1 DE1007 2 DE6000 3 DE6004 4 DE6015 5 DE6006 DE5024 6 DE6007 7 DE0027 tagout)QH441OperationManual Crusher Works

Small Scale Mechanized Stone Crusher, Mechanical Design

2021年7月26日 jaw crusher that employs the simple technology of a four bar mechanism, and design a small scale mechanized jaw crusher for crushing the stones into aggregates This mechanism will help to evaluate its effectiveness in comparison with other different types of mechanisms in use especially the double toggle and the modified single toggle 2021年12月1日 The purpose of this research is to develop an automated control system for Jaw crusher production process as a solution for the real specified problems to get more productive aggregate production (PDF) Automated process control system of Jaw crusher Air Classifiers Accurate Fines Control for Engineered Sands Brochure 8 Pages Cyclonic Ultrafine Classifier Technical Data Sheet 2 Pages Centrifugal Air Classifier for Fly Ash Processing 2 Pages Air Classifier Options Data Sheets 2 Pages VERTIMILL® Lime Slaker Technical Sheet and QuestionnaireAll Corporation catalogs and technical brochures

What Are Jaw Crushers and How Do They Work? Oreflow

March 28, 2019 / in News A jaw crusher is a large piece of equipment that’s used in mine and ore processing plants to crush rocks The equipment was first introduced back in 1858 by inventor Eli Whitey Black who primarily developed machinery used for crushing stone From there, jaw crushers have seen plenty of action in the pit and quarry 2020年3月19日 PDF A parameter study using a jaw crusher is designed to investigate the influence of feed gradation, feed rate, crusher setting and crusher speed on Find, read and cite all the research (PDF) Influence of jaw crusher parameters on the quality of The core of ® C Series™ jaw crusher is a pinned and bolted, nonwelded frame construction that provides excellent fatigue strength All the frame components are casted using an alloy developed inhouse ® C Series™ jaw crushers

Jaw Crusher Handbook Stone Crusher PDF JXSC

Safe Operating Procedure 1 Before starting, all jaw crusher parts must be fastened installed The tail traction spring is suitable loose, and the engine oil is installed in the swing bolster 2 Jaw rock crusher must test run 2 2018年10月15日 • After a new jaw die installation, rotate the singlepiece jaw dies when 30% of the tooth profile is worn • Rotate a second time when the tooth profile at the bottom of the jaw die is completely worn This procedure allows for good work hardening of the manganese jaw dies, and helps maintain the best nip angle for maximum throughput ® C Series™ jaw parts2020年4月1日 The Sandvik jaw crusher line is designed for the motor sizes listed in RPG and technical specifications This means that for harder materials, the crusher will have to be operated at larger settings to avoid overload of drive and/or motor Using oversized motors will lead to radically shorter crusher life and various mechanical problemsSANDVIK JAW CRUSHER SERIES Sandvik Mining and

Engineered for the toughest feed materials ®

2020年7月24日 lifetime of the jaw crusher C Series jaw crushers are modular for quick, easy installation and commissioning in new plants and when replacing old jaw crushers This minimizes onsite engineering and fabrication, saves time, and reduces installation and structural costs The integral motor base reduces space requirements andTechnical specifications ® C Series™ jaw crushers C80™ Technical specifications ® C Series™ jaw crushers C106™ Crusher throughput capacity, scalped feed material Capacity 55 75 Closed side setting Crusher throughput capacity, nonscalped feed material Closed side setting 40 mm Mtph Stph Benefits of primary crushing with scalping ® C Series™ jaw crushers Corporation PDF 2014年4月1日 Jaw crushers are the most common solution in underground applications when the throughput is below 1000 tonnes per hour, depending somewhat on the scalping solutions Above 1000 tph, primary gyratory crushers are an option After the throughput reaches 2000 tph, jaw crushers are very rare, with the exception of a parallel plant layoutBelow the surface: Setting up an underground primary jaw crusher

Jaw crushr operate manual: how to install, repair and

2022年9月30日 Installation points of the movable jaw Assemble the movable jaw parts in advance After assembling the movable jaw, movable jaw shaft, movable jaw plate, toggle pad, etc on the ground, use a crane or crane to hoist the assembled parts together on the crusher In the rack For sliding bearings, it is necessary to grind and match between the The inclination is guaranteed to be 02 mm, and the coaxiality is less than 006 mm The installation of the movable jaw is completed 6 Installation of tooth plate Jaw crusher tooth plate is directly used for crushing ore parts Its structure is simple, but because of frequent contact with the ore, tooth plate is the crusher wear quicklyInstallation of Jaw Crusher Skills and Notes JXSC Mine2020年4月15日 and heavier components can allow for process optimization (greater throughput/higher reduction) after installation Maintenance The TS gyratory crusher is distinguished from other gyratory crushers by its revolutionary design which allows major service and maintenance functions to be safely performedCrushing Systems