عنا

مرحبا هل يمكنني مساعدتك؟

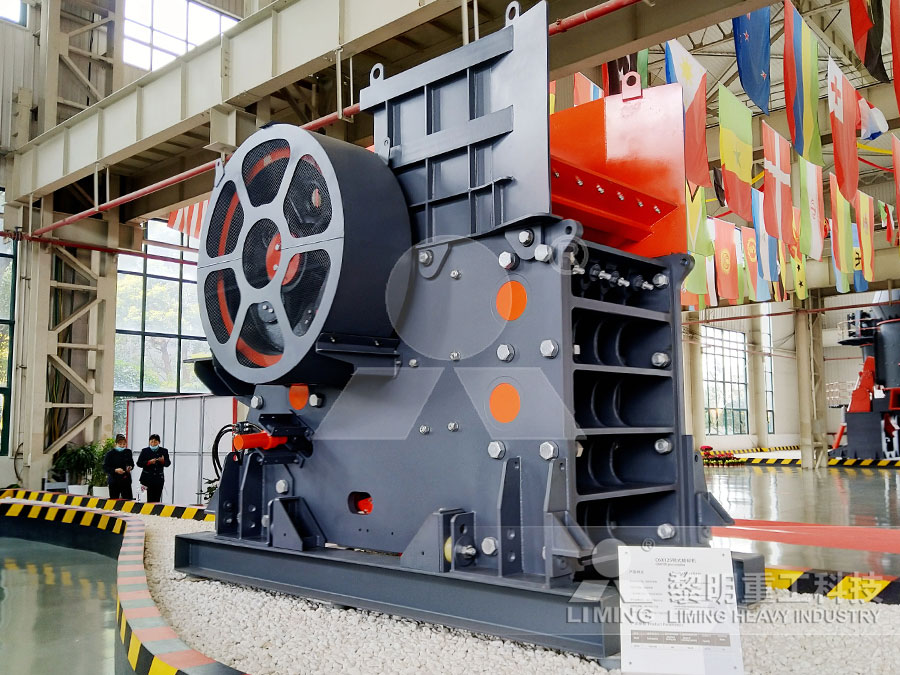

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

ball mill screening concrete

2023-01-19T18:01:19+00:00

What to expect from a cement ball mill inspection

2019年5月2日 What to expect from a cement ball mill inspection Having an independent audit of your cement mill can identify opportunities for productivity improvements, 2023年3月21日 A ball mill is a device that grinds hard minerals into a powder by employing abrasion, using steel balls and horizontal blades that are permanently Processing of laboratory concrete demolition waste using ball mill Ball mill is the key equipment for grinding materials after crushing and screening It is also commonly used in grinding equipment Ⅰ It is mainly used in refractory, fertilizer, BALL MILL FOR ALL YOUR NEEDS

What to expect from a cement ball mill inspection GCP Applied

2019年5月2日 What to expect from a cement ball mill inspection May 02, 2019 by GCP Applied Technologies Having an independent audit of your cement mill can identify The steel ball screening device is simple in structure, high in screening efficiency, high in degree of automation, low in labor intensity, and low in use cost The invention discloses aCNA Steel ball screening device of ball grinding mill 2020年7月26日 Controllers are necessary for the cement ball mill grinding process to automate the plant for providing less energy per unit production of cement The plant Predictive Controller Design for a Cement Ball Mill

Ball Mill Screens Crusher Mills, Cone Crusher, Jaw Crushers

Vibrating Screen – Ball Mill Grinding for SaleManufacturer liming is a manufacturer of vibrating screen Vibrating screen can be used in coal, concrete sieving This page is 2021年6月10日 One of the most critical variables in the cement ball mills is ventilation A mixture of hot and recycled air would deliver and dry the powder in a cement ball mill as a pulverizing system Thus, ventilation in Ventilation Prediction for an Industrial Cement Raw Ball Ball Mill, Ball Mill Price Supplier,Cement Concrete Ball Mill For Sale There are many types of grinding mill, such as ball mill, crusher plant cad drawing; balls for cement Ball Mill Concrete Crushing Plant Crusher Mills, Cone Crusher, Jaw

Crushing Screening Plant 911 Metallurgist

2016年7月12日 The Hollinger crushing plant is one of the largest and most uptodate plants in Canada Of steel and concrete construction throughout, high headroom is provided so that, with the exception of a single lift through shuttle conveyors to Nos 2 and 3 screens, there is gravity flow to all machines (see Fig 10)Fly Ash Ball Mill Simplify production process Reduce energy consumption by 30% Capacity: 65615t/h Applicable materials: Fly ash, cement clinker, construction waste, etc Get Price Now The fly ash ball mill is important Use Fly Ash Ball Mill Make Flyash Cement Ball Mill deposit Processing operations may include crushing, screening, size classification, material handling and storage operations All of these processes can be significant sources of PM and PM10 emissions if uncontrolled Quarried stone normally is delivered to the processing plant by truck and is dumped into a bin11192 Crushed Stone Processing and Pulverized Mineral Processing

BALL MILL FOR ALL YOUR NEEDS

Ball mill is the key equipment for grinding materials after crushing and screening It is also commonly used in grinding equipment Ⅰ It is mainly used in refractory, fertilizer, cement and glass The ball mill should install on steady concrete groundwork The foundation designed and the construction looks at general drawing and A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and paints Ball mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium Different materials are used as media, including ceramic balls, flint pebbles Ball mill Wikipedia1 views, 0 likes, 0 loves, 0 comments, 0 shares, Facebook Watch Videos from Grinding Ball Mills: GENERAL MACHINE STONE CRUSHING SCREENING AND CONCRETE PLANTS®GENERAL MACHINE STONE CRUSHING SCREENINGGENERAL MACHINE STONE CRUSHING SCREENING AND CONCRETE

OTHER MACHINERY EQUIPMENT GST RATES HSN CODE

01/07/2017 18% Machinery, Apparatus And Equipment (Other Than The MachineTools Of Headings 8456 To 8465), For TypeFounding Or TypeSetting, For Preparing Or Making Printing Blocks, Plates, Cylinders Or Other Printing Components; Printing Type, Blocks, Plates, Cylinder 18Coal mill is the main equipment in the pulverized coal preparation processBecause calcining topgrade cement clinker requires a stable supply of coal powder as the fuel of cement kiln, and more than 85% of pulverized coal should be finer than 200 mesh, water content less than 2%, and calorific value more than 6000Kcal/kg, therefore the pulverized Cement Mill Cement Grinding Machine AGICO Cement Grinding Mill2019年9月29日 Switch on the power supply of the ball mill and press the accident button to stop the machine after normal rotation Check the main bearing, motor and gear size to determine whether the ball mill is rotating in the right direction If there is no abnormal situation, start the ball mill to run for 8 hours4 Steps to Debug Ball Mill

Ventilation Prediction for an Industrial Cement Raw Ball Mill

2021年6月10日 In cement mills, ventilation is a critical key for maintaining temperature and material transportation However, relationships between operational variables and ventilation factors for an industrial cement ball mill were not addressed until today This investigation is going to fill this gap based on a newly developed concept named “conscious laboratory Contribute to crushers/china development by creating an account on GitHubGitHub china/ ball mill screening inzalomd at main50 micrometers ( m) or smaller by grinding, using smooth rolls, media mills, autogenous mills, hammer mills, or jet mills The ground material then is classified by wet screening, dry screening, or air classification At some plants, after initial crushing and screening, a portion of the sand may be diverted to construction sand use11191 Sand And Gravel Processing US EPA

Laboratory Ball Mills Bench and Floor Jar Mills

Benchtop Lab Mill Jar Mills are available in bench or floor models and have one to six jar capacities in 1, 2 or 3 tiers They are used for wet or dry grinding, mixing and blending of ores, chemicals, ceramics, glass, and VIBRADRUM® Grinding Mills excel over conventional ball, stirred media, or vertical roller mills in both grinding and energy efficiency The features listed below highlight why our mills are so effective and efficient Proven energy savings range from 35 to 50% reductions in kW hours per ton of processed materialGrinding Crushing Mill VIBRADRUM® General KinematicsScreening used Concrete recycling line Vibrating screen is main equipment in Separation system,which is a kind of new screening equipment, the vibrating track is a circle, and it is designed for especially screening stone stock of quarry, and also for classifying products of such departments as Concrete recycling,quarry processing, building materials, electricity Concrete screening, Manufacturer, Price,Vibrating screening

Ball Mill Adalah? Prinsip Kerja, Bagian, Komponen Dan Fungsinya

2022年10月5日 Ball Mill adalah suatu mesin yang berbentuk silinder (tabung) dan berfungsi untuk menggiling material kasar menjadi material yang halus Mesin ini memanfaatkan bolabola keras untuk menumbuk dan menggesek material kasar sehingga bisa menjadi halus Ball Mill menjadi salah satu mesin yang sangat penting dalam The unique amalgamation of high friction and collision results in exceptionally fine particles within the shortest amount of time Ball mills are very useful for fine grinding of the materials like limestone, clinker, iron ore and other minerals Mills of varied capacity 2 kg, 5 kg 10 kg are available with recommended quantity of grinding HighPerformance Ball Mills for Mineral Comminution insmart Contribute to chengxinjia/ development by creating an account on GitHub/ ball mill screening constructionirelandmd at main

/ ball mill screening smashersmd at master

ball mill screening smashersgraphite processing crush grind float DBM Crusher ensp#0183enspgrinding mill for mineral dressing processes paints ncrete crusher hammer strisciando2016 new rent demolition rd 20 hydraulic rotating concrete rock crusher shear,fits 35 k to 70 k excavators 18,500,if needed we can make a new 2013年2月26日 Ball mills are built at the supplier’s factory and transported to the cement producer’s site In contrast, the vertical mill is built onsite at the cement plant, avoiding difficult logistical issues and associated costs The equipment costs are higher for a VRM than a ball mill, reflecting the greater complexity of the system, which Comparing ball mills and VRMS for cement grindingVipeak Heavy Industry is the manufacturer of Jaw Crusher,Stone Crusher,Cone Crusher,Grinding Mill,Ball Mill,etcWith the latest manufacturing technology, the unique structural design,we produce the high standard, qualified stone crushers and grinding mills, we provide you the detailed information of Jaw Crusher,Stone Crusher,Cone Grinding Mill, Ball Mill // Vipeak Heavy Industry

AIMIX Ball Mill For Sale For Gold Mining Processing

The ball mill is the key equipment for crushing materials after they have been crushed It is suitable for grinding ores and other materials and is widely used in nonferrous metal mining, nonmetallic mining building Mill lining installation in a ball mill at Atacama Kozan Mining Company, Copiapo, Chile Ball mills designed for long life and minimum maintenance overflow ball mill sizes range from 5 ft x 8 ft with 75 HP to 30’ x 41’ and as much as 30,000 HP Larger ball mills are available with dual pinion or ring motor drives Ball Mills Brochure Corporation PDF Catalogs Lorem ipsum dolor Address: No169, Science (Kexue) Avenue, Tel: 0086371 : [ protected]ball mill screening general

Ball Mill Concrete Crushing Plant Crusher Mills, Cone Crusher,

Screening And Crushing Christ; Stone Crusher Machine; Asphalt Rap Crushers; Big Crusher Sand Pumping Machine; Yg1142e710 Mobile Portable Crushing; The commonly used grinding mill are concrete ball mill, concrete super thin grinding mill and so on cement ball mill media for crushing rockBall Mill an overview ScienceDirect Topics The ball mill is a tumbling mill that uses steel balls as the grinding mediaThe length of the cylindrical shell is usually 1 15 times the shell diameter (Figure 811)The feed can be dry,with less than 3% moisture to minimize ball coating,or slurry containing 20 40% water by weight vertical impact ball mill drawing Apr GitHubBall mills are used primary for single stage fine grinding, regrinding, and as the second stage in two stage grinding circuits According to the need of customers, ball mill can be either wet or dry designs Ball mills have been designed in standard sizes of the final products between 0074 mm and 04 mm in diameterBall Mill Features,Technical,Application, Ball Mill Manufacturer

McLanahan Hammermill Crushers

Hammermill Crushers Hammermill Crushers are known for providing greater reduction ratios in a variety of materials for the aggregate and industrial markets The heavyduty, rugged construction of all Universal Hammermills allows for greater applied forces to achieve higher production rates with controlled product top size and gradation2020年5月8日 Ball mill machine has always been the main grinding equipment in wet cement production In the early years, the rod mill was first used in cement raw meal grinding, which increased the output of the grinding section by 31%, saved energy by 27%, and reduced the consumption of grinding media by 47%Comparative Analysis of Rod Mill and Ball Mill2021年6月23日 ball mill screening 20mm ball mill screening 20mm Ball End Mills Travers Tool Co Inc Ball End Mills have a hemispherical tip used to machine rounded details such as the metal bearing grooves found in machines Also called Ball Nose End Mills they are used extensively in manufacturing tools amp dies and machining complex Ball Mill Screening Complete

Ventilation Prediction for an Industrial Cement Raw Ball Mill by

the mill partitions, feed rate, the hardness of the feed material, and ball sizes in the mill compartments Understanding the relationships between these variables from the grinding units can play an essential role in efficiently operating cement production lines [3–5] One of the most critical variables in the cement ball mills is ventilation2023年1月5日 When the shock force of the ball mill material is 12,500 kN, the concrete grade is C35, the shock angles are set to 10°, 20°, 30°, 40° and 50° respectively, and the dynamic responses of the Study on shock vibration analysis and foundation reinforcement of Generally, filling the mill by balls must not exceed 30%–35% of its volume The productivity of ball mills depends on the drum diameter and the relation of ∫ drum diameter and length The optimum ratio between length L and diameter D, L: Ball Mill an overview ScienceDirect Topics

Crushing and Screening Handbook AusIMM

screening, and for those seeking a greater focus on mining, ’s minerals processing handbook is also available This is an updated version of the Crushing and Screening Handbook, the fi rst edition of which was published a couple of years ago The changes in this 5th edition involve only minor updates and corrections2013年4月1日 Based on experience acquired over the years and the investigative work conducted by FC Bond, it was established that the optimum circulating load for a closed ball mill – cyclone circuit is around 250% This value is used as guideline for the design of new circuits as well as to assess the performance of existing circuitsClosed circuit ball mill – Basics revisited ScienceDirectOnce the concrete sample has been remixed, start taking the slump tests within 5 minutes Start by filling a mold 12 inches high in the shape of the frustum of a cone that is 8 inches in diameter at the bottom and 4 inches in diameter at the top Fill the mold in three equal layers by volume, not by heightConcrete Testing Procedures Tests for Slump More Concrete

Ball Mill Mineral Processing Equipment Machine

Advanced ball mills and mineral processing equipment help mining companies around the world process minerals more efficiently rock crushers, grinders, classifying screening machines, washing machines, gravity separators, flotation machines, magnetic separators, electric separators, dewatering equipmentand laboratory mineral processing \n \n \n jaw crusher rock crushing machines for sale crusher mills \n \n \n ball mill mfg in mumbai \n \n \n carbonate medium speed sanding machineGitHubLaval Lab, the onestop specialist in Milling For over 35 years Laval Lab Inc is the onestop specialist for size reduction of all types of materials We have the right crusher, pulveriser, grinder or mill for the laboratory to pilot plant sample processing We serve all major industries such as mining and metallurgy, chemistry, pharmaceutical Crushers, Pulverizers, Grinders – Lavallab

CNU Ball mill with screening function Google Patents

The utility model relates to a grind the processing field, disclose a ball mill with screening function The utility model discloses in, the ball mill surface is rotated and is connected with the support frame, the ball mill is located inside one side surface of support frame and has seted up the sieve mesh, the inside material of grinding of ball mill falls into inside the 2016年7月12日 The Hollinger crushing plant is one of the largest and most uptodate plants in Canada Of steel and concrete construction throughout, high headroom is provided so that, with the exception of a single lift through shuttle conveyors to Nos 2 and 3 screens, there is gravity flow to all machines (see Fig 10)Crushing Screening Plant 911 MetallurgistFly Ash Ball Mill Simplify production process Reduce energy consumption by 30% Capacity: 65615t/h Applicable materials: Fly ash, cement clinker, construction waste, etc Get Price Now The fly ash ball mill is important Use Fly Ash Ball Mill Make Flyash Cement Ball Mill

11192 Crushed Stone Processing and Pulverized Mineral Processing

deposit Processing operations may include crushing, screening, size classification, material handling and storage operations All of these processes can be significant sources of PM and PM10 emissions if uncontrolled Quarried stone normally is delivered to the processing plant by truck and is dumped into a binBall mill is the key equipment for grinding materials after crushing and screening It is also commonly used in grinding equipment Ⅰ It is mainly used in refractory, fertilizer, cement and glass The ball mill should install on steady concrete groundwork The foundation designed and the construction looks at general drawing and BALL MILL FOR ALL YOUR NEEDSA ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and paints Ball mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium Different materials are used as media, including ceramic balls, flint pebbles Ball mill Wikipedia

GENERAL MACHINE STONE CRUSHING SCREENING AND CONCRETE

1 views, 0 likes, 0 loves, 0 comments, 0 shares, Facebook Watch Videos from Grinding Ball Mills: GENERAL MACHINE STONE CRUSHING SCREENING AND CONCRETE PLANTS®GENERAL MACHINE STONE CRUSHING SCREENING01/07/2017 18% Machinery, Apparatus And Equipment (Other Than The MachineTools Of Headings 8456 To 8465), For TypeFounding Or TypeSetting, For Preparing Or Making Printing Blocks, Plates, Cylinders Or Other Printing Components; Printing Type, Blocks, Plates, Cylinder 18OTHER MACHINERY EQUIPMENT GST RATES HSN CODE Coal mill is the main equipment in the pulverized coal preparation processBecause calcining topgrade cement clinker requires a stable supply of coal powder as the fuel of cement kiln, and more than 85% of pulverized coal should be finer than 200 mesh, water content less than 2%, and calorific value more than 6000Kcal/kg, therefore the pulverized Cement Mill Cement Grinding Machine AGICO Cement Grinding Mill

4 Steps to Debug Ball Mill

2019年9月29日 Switch on the power supply of the ball mill and press the accident button to stop the machine after normal rotation Check the main bearing, motor and gear size to determine whether the ball mill is rotating in the right direction If there is no abnormal situation, start the ball mill to run for 8 hours2021年6月10日 In cement mills, ventilation is a critical key for maintaining temperature and material transportation However, relationships between operational variables and ventilation factors for an industrial cement ball mill were not addressed until today This investigation is going to fill this gap based on a newly developed concept named “conscious laboratory Ventilation Prediction for an Industrial Cement Raw Ball Mill