عنا

مرحبا هل يمكنني مساعدتك؟

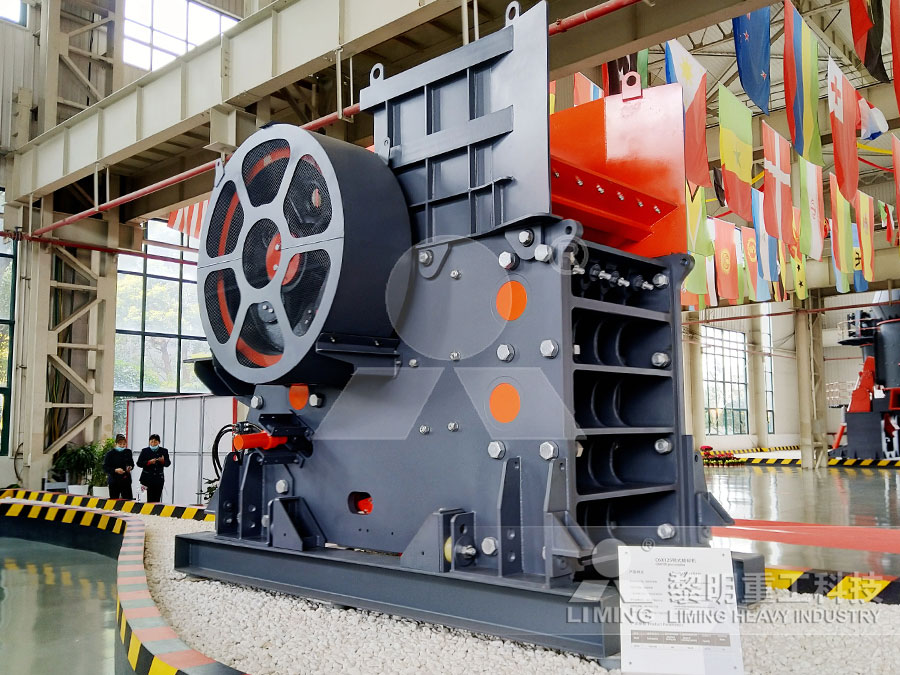

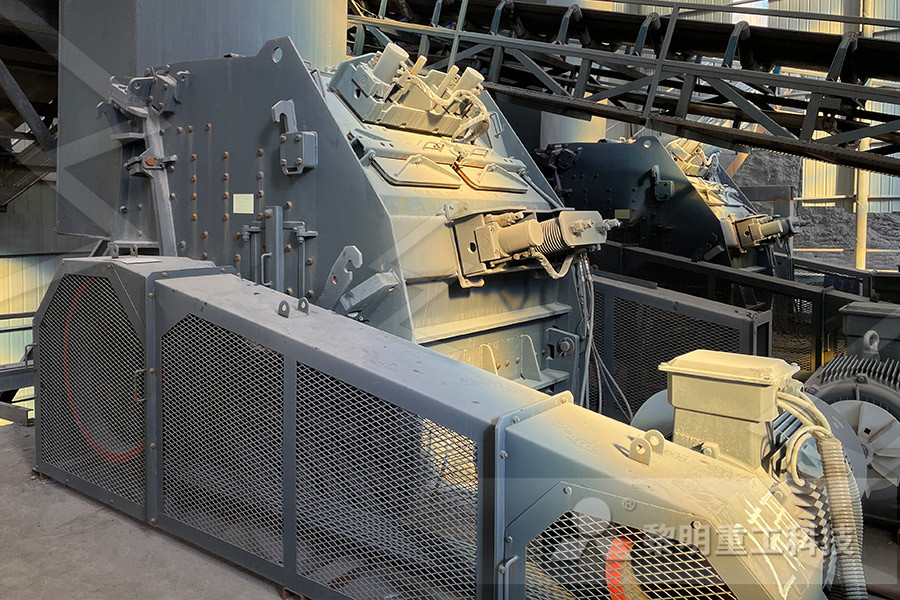

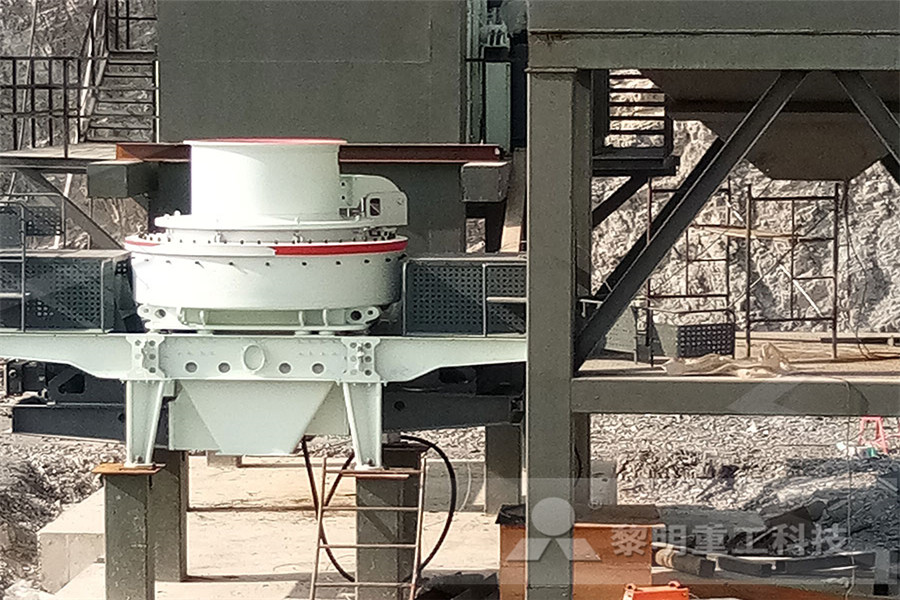

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

equipment for course coal separation

2023-09-05T07:09:32+00:00

A review of intelligent coal gangue separation technology and equipment

2023年11月6日 Intelligent coal gangue separation equipment has the advantages of fast speed, high precision, strong modularity, and integration scalability It also has the advantages of low operation cost and energy consumption, convenient operation and 2023年9月26日 There are two main methods of extracting coal by underground mining: roomandpillar (or, bordandpillar) and longwall mining Roomandpillar mining involves Coal Mining Equipment,Coal Mining Methods,OpenCut Upcoming cources Brisbane — 1416 September 2021 The Coal Quality Course provides an understanding of the importance of managing coal quality from the exploration to equipment for course coal separation

Types of Machinery used in Coal Mining workpac

Coal mines across Australia rely on machinery and machinery operators to extract coal day in day out Check out our infographic for a guide to some commonly used pieces of 2023年1月1日 This chapter discusses current developments and latest applied solid–liquid separation (SLS) technologies and equipment used for coal The chapter commences Solid–liquid separation technologies for coal ScienceDirect2023年1月12日 Abstract This paper introduces the composition structure, system function and implementation method of the centralized control system of coal preparation Study on Corrosion Wear and Protection of Coal Preparation Equipment

Solid–liquid separation technologies for coal ScienceDirect

2013年1月1日 The separation technologies applicable for coal dewatering are dependent on the coal particle size, with centrifuges (vibrating basket and screen scroll types) most Abstract: This paper covers the use of magnetic separation equipment to remove "tramp iron" from processed coal to protect possible damage to belts, cruhers, hammermills, and Magnetic separation equipment for coal applications IEEE 2020年10月26日 In the last 10 years beneficiation methods for coal and other minerals was changed Dry beneficiation equipment can be divided into two categories: typical gravity Modern Methods of Dry Mineral Separation Polish Experience

SolidLiquid Separation Equipment Weir

At Weir, we supply a wide range of solidliquid separation equipment for mining, aggregate and general industries including centrifuges, thickeners and filter presses Solidliquid 2018年9月1日 The most often used equipment in the gravitational separators include jigs (Falconer, 2003), spirals (Falconer, 2003;Sadeghi et al, 2014), falcon (Gülsoy and Gülcan, 2019), knelson (Knelson and A new method for gravity separation: Vibrating table gravity 2023年8月22日 The precise identification of damp, sticky coal gangue; efficient jet nozzle separation; and process layout in a narrow, restricted space are essential technologies for gangue source reduction based on underground gangue photoelectric separation, which is critical for the longterm growth of coal mines In this paper, the Xray absorption fine Processes Free FullText Gangue Source Reduction

Coal Processing Multotec

Coal processing or coal beneficiation uses physical (mechanical) and/or chemical methods to remove rocks, dirt, ash, sulphur and other contaminants and unwanted materials to produce highquality coal for 2021年8月24日 The separation chamber is equipped with key equipment such as GPS5010 toothed roller disc screen, 2PLF70150 crusher, QZK1533 slime highfrequency screen, and WD2000 movablesieve jigger, wherein the jigger is suitable for gangue separation of particles (50–300 mm), achieving the separation capacity of 42 million t/aIntegrated green mining technology of “coal mininggangue 2017年12月10日 1 Introduction Gangue minerals accounts for between 15% and 20% of raw coal in China (Qian et al, 2007)Indeed, as coal production has increased, so has gangue generation; by the end of 2009, the total amount of gangue produced added up to 50 × 10 9 t, encompassing 40% of the total Chinese solid waste (Miao and Qian, Separating coal and gangue using threedimensional laser scanning

Magnetic Separators Multotec

Magnetic Separators Multotec supplies a complete range of magnetic separation equipment that effectively separates ferromagnetic and paramagnetic particles from dry solids or slurries Magnetic separators are renowned for their separation of magnetic ore; they can also serve as an electromagnet – effective for removing tramp metals Dewatering is a process that separates liquidsolid mixtures, such as slurries comprised of particles and process water, that are present in aggregate, minerals, coal and frac sand wet processing applications Dewatering most often occurs through processes such as wet classification, centrifugation, filtration or similar liquidsolid separation McLanahan Dewatering2022年9月9日 Dry permanent magnetic separators have been widely used in the mineral and coal processing industries due to their simple operation and high separation efficiency These tools not only discard some amount of bulk gangue from the raw ore, thereby reducing the volume of the grinding operation and cutting energy consumption, but also Minerals Free FullText Dry Permanent Magnetic Separator

Spiral Concentrator Multotec

Multotecdesigned spiral concentrators are used across the world in coal, gold, iron ore, mineral sands, platinum and chrome processing plants as part of the beneficiation process and separates ore and material between 38 and 2 000 microns As a turnkey supplier of gravity concentration equipment across the world, Multotec delivers endtoend 2015年4月15日 The traditional acid–base separation method can cause serious environmental problems In this research, imidazole and its homolog compounds were designed as new extraction agents for the separation of phenols from coal tar, which can form deep eutectic solvent with phenols with the removal efficiencies more than 90%The new liquid–liquid extraction method for separation of 2019年4月9日 China is the world’s largest coal producer country However, largescale coal mining has led to severe environmental pollution issues such as surface subsidence and gangue piling up The gangue Overview of Solid Backfilling Technology Based on

Centrifuges for dewatering separation

Lower your operating costs with our efficient mining centrifuges Optimised dewatering and material separation will cut both your operating and capex costs, as you reduce your environmental impact Our advanced designs and experienced, qualified experts will ensure you receive the ideal equipment for your application, and the support you need 2017年3月4日 The process "Comminution" involves size reduction and sizewise classification called as screening or separation The objective of this report is to provide the details of size reduction methods (PDF) SIZE REDUCTION BY CRUSHING METHODS2022年7月1日 The training results show that the training correlation under the monomer characteristics has a better effect on the classification of characteristic quantity, and the sorting accuracy of coal gangue is 90% and 91%, respectively equipment failure and other shortcomings (See Fig 1) As a new coal separation system, the intelligent Research on intelligent optimization separation technology of coal

Solid–liquid separation technologies for coal ScienceDirect

2023年1月1日 Solid–liquid separation (SLS), the removal of water from coal product and tailings, is required after wet coal cleaning technologies such as wet gravity separation and flotation for moisture removal The lower the product moisture, the higher the calorific value of the coal, and the higher the efficiency of coal combustion, carbonization, and 2020年3月15日 Under this condition, the −3 mm dry screening has become the core technology of the steam coal separation Conventional steam coal separation involves the −13(25) mm classification of raw coal and the consumption of the −13 mm raw coal with nonseparation, leading to the loss of a large amount of clean coal and high ash content Kinematics of a novel screen surface and parameter optimization for Magnetic and Electrical Separation Barry A Wills, James A Finch FRSC, FCIM, PEng, in Wills' Mineral Processing Technology (Eighth Edition), 2016 1343 Material Transport in Magnetic Separators Commercial magnetic separators are continuousprocess machines, and separation is carried out on a moving stream of particles passing into and through Magnetic Separator an overview ScienceDirect Topics

Washability an overview ScienceDirect Topics

Gravity Separation A Gupta, DS Yan, in Mineral Processing Design and Operation, 2006 1574 SinkFloat Alternatives Because of the importance of washability and sinkfloat analysis to the coal industry and the health hazards associated with organic liquids, considerable effort is being aimed at alternatives to the organic liquid method To 2023年2月2日 The availability of lowgrade coal with a high amount of ash has urged the improvisation of separation equipment with minimal or no water utilization The present work addresses the study on the separation equipment performance with different moisture coal The experimental results were obtained in terms of separation parison of the prediction performance of separating coal 2021年12月8日 US REGULATIONS MINE SAFETY HEALTH ADMINISTRATION (MSHA) •30 CFR Part 75 Mandatory Safety Standards for Underground Coal • Separate split of air to each section exhaust to return §75332 • Main fan on surface, explosion proof installation NO BOOSTER • Face ventilation installation §75330 • Minimum quantities §75325 • MINE VENTILATION BEST PRACTICES AND

A novel and low cost coal separation process: Combination

2020年5月1日 The current development direction of coal separation technology in China is aimed at studying and popularizing advanced equipment, optimizing the design of power coal washing processes, improving the quality of commercial coal, and reducing infrastructure investment and production costs [[6], [7], [8], [9]]16 小时之前 In 2022, the Department of Energy announced important new funding opportunities under the IIJA, including USD 45 million for CCUS in power and industrial applications; USD 820 million for largescale carbon capture pilot projects; and USD 17 billion for carbon capture demonstration projects In April 2023 the United States Carbon Capture, Utilisation and Storage Energy System IEAFor the best in resource recovery and recycling equipment, look no further than General Kinematics Established in 1960, GK has spent more than six decades optimizing our machinery, processes, and support for you and your company General Kinematics leads the market in foundry and metal casting, coal and energy generation, mining and minerals Recycling Equipment Machinery General Kinematics

Ore, Rock Aggregate Screening (Complete Guide) 911

2016年6月20日 AZ Guide to Screening Ore, Rock Aggregate A simple definition of a “screen” is a machine with surface (s) used to classify materials by size Screening is defined as “The mechanical process which accomplishes a division of particles on the basis of size and their acceptance or rejection by a screening surface”equipment, the coal preparation process has gradually developed in the direction of automation and intelligence In the HM coal preparation process of a coal preparation plant, if the quality of the raw coal changes, the suspension process parameters will also fluctuate, which will cause a certain degree of adverse impact on the product qualityNQIEREVOIR IOPscience2019年7月15日 In general, coal ash can be divided into three components: slag, bottom ash, and fly ash The majority of coal ash produced in modern utility boilers is fly ash [74]The principle components of fly ash are unburned carbon and spherical ash components, including glass cenospheres, magnetic particles, and fine Si Al ash [11, 76], Separation of unburned carbon from coal fly ash: A review

Recovery of residual carbon from coal gasification fine slag

CGFS is similar to coal (Fig 2 (a)), which revealed rutile and quartz as its main mineral phases along with small amounts of aqualite and hematiteIn addition, CGFS is mainly composed of clumped residual carbon and glassballstructured inorganic minerals (ie, ash components) (Fig 2 (b) and (c))CGFS exhibited an N 2 adsorption–desorption curve Coal washings and tailings treatment at their finest Coal producers everywhere are under pressure to improve everything from washing efficiency and throughput to water recycling and environmental safety Our separation specialists tackle these challenges based on decades of experience recommending, configuring, and commissioning a wide range Coal AndritzSeparation and Beneficiation Systems for Sand, Gravel, Ore, Coal, Lignite and Slag ANDRITZ SEPARATION Solid and Liquid Separation and Refining Solutions for Beneficiation Filter Plates and Separation Equipment Minopex Operation and Maintenance of MineralProcessing Facilities Multotec Mineral Processing Solutions Separation Equipment Mining Technology

Multiple parameter collaborative optimization of a particle separation

2021年8月1日 1 Introduction Owing to its abundant reserves, coal is the main energy source in China and is the most important and fundamental guarantee in the Chinese energy strategy [1], [2]In 2019, the raw coal production of China amounted to 385 billion tons, representing a yearonyear increase of 40%, while the coal consumption increased by Our worldleading beneficiation spirals give you confidence in fine coal processing Mineral Technologies’ range of MD spirals are the leading spiral of choice for fine coal separation in many Australian coal washeries Coal beneficiation Commodities Mineral 2021年5月8日 Treating mine water as a resource is the only way to alleviate water shortage and the environmental pollution issues generated at mining sites in areas of northern and western China By investigating 77 coal mine water treatment stations in western China, we sought to analyze the application status, direct operating costs, and Application Overview of Membrane Separation Technology in Coal

Fluidization and separation characteristics of gas–solid separation

2018年5月1日 In addition, the separation tests of three raw coal samples showed that the research results of binarysimulated coal particles composed of quartz sand and clean coal were valid Under the optimal conditions, the ash content of clean coal products of three raw coal samples can be reduced by 7565%, 7903%, and 8303%, respectively2019年9月5日 The raw coal selection rate has reached 718% The number of coal preparation plants has reached more than 2300 New technologies, new equipment and new processes Jigger (B=5000mm+) Dense medium cyclone (Max Φ=1600mm) Shallow groove separator(Max B=7925mm) Flotation machine (Max=120m 3) Development of Research Progress in Dry Beneficiation University of 2021年12月1日 Further, after the separation process in the fluidized bed, the cleaned coal product with a yield of 4277 and an ash content of 869% is enriched from 1 to 3 mm coking middling coal (ash content of 282%), indicating that coking middling particles are separated efficiently in the liquidsolid fluidized bedRecent progress and potential challenges in coal

Development overview of paste backfill technology in China’s coal

2021年10月12日 Although coal has made a great contribution to China’s economic and social development, the traditional mining methods of coal resources have caused many problems (Ahern and Hendryx 2012; Adibee et al 2013; Bernhardt et al 2012; Chen et al 2014; Hussain et al 2016; Kurth et al 2015; Song and Wang 2019), such as the 2007年2月1日 The rawcoal feeding system and the upward medium current flow in a densemedium vessel (DMV) arc, in addition to the residence time of particles in the separator, important factors for efficient coarse particle separation The feed material from a raw coal screen and/or prewet screen merge with the major volume of circulating Analysis of a densemedium separator for coarse coal separation 2023年11月3日 Our sorting equipment or mineral processing equipment, specially developed for mining applications, enables processes to be better controlled, and through ore sorting even ores that were previously not economically viable, can be efficiently and profitably processed And our STEINERT technology is even effective in situations in Mining separation and sorting equipment for processes in the mining

Coal Preparation SpringerLink

According to the annual census of coal preparation plants conducted by Coal Age [], the USA operates 286 coal preparation plants in 12 statesThis number is relatively small by comparison to the worldwide fleet which is estimated to be 2,283 plants []The capacity of the plants can range from less than 200 t/h for small operations to 6,000 t/h or more for 2021年12月7日 Employees only need a short time of training to operate (4) The amount of overhaul and maintenance is small which provides a reference for other coal preparation plants to use dry coal separation equipment to separate raw coal of similar coal quality DRY COAL PREPARATION HAS ADVANTAGES OVER 2018年9月1日 The most often used equipment in the gravitational separators include jigs (Falconer, 2003), spirals (Falconer, 2003;Sadeghi et al, 2014), falcon (Gülsoy and Gülcan, 2019), knelson (Knelson and A new method for gravity separation: Vibrating table gravity

Processes Free FullText Gangue Source Reduction

2023年8月22日 The precise identification of damp, sticky coal gangue; efficient jet nozzle separation; and process layout in a narrow, restricted space are essential technologies for gangue source reduction based on underground gangue photoelectric separation, which is critical for the longterm growth of coal mines In this paper, the Xray absorption fine Coal processing or coal beneficiation uses physical (mechanical) and/or chemical methods to remove rocks, dirt, ash, sulphur and other contaminants and unwanted materials to produce highquality coal for Coal Processing Multotec2021年8月24日 The separation chamber is equipped with key equipment such as GPS5010 toothed roller disc screen, 2PLF70150 crusher, QZK1533 slime highfrequency screen, and WD2000 movablesieve jigger, wherein the jigger is suitable for gangue separation of particles (50–300 mm), achieving the separation capacity of 42 million t/aIntegrated green mining technology of “coal mininggangue

Separating coal and gangue using threedimensional laser scanning

2017年12月10日 1 Introduction Gangue minerals accounts for between 15% and 20% of raw coal in China (Qian et al, 2007)Indeed, as coal production has increased, so has gangue generation; by the end of 2009, the total amount of gangue produced added up to 50 × 10 9 t, encompassing 40% of the total Chinese solid waste (Miao and Qian, Magnetic Separators Multotec supplies a complete range of magnetic separation equipment that effectively separates ferromagnetic and paramagnetic particles from dry solids or slurries Magnetic separators are renowned for their separation of magnetic ore; they can also serve as an electromagnet – effective for removing tramp metals Magnetic Separators MultotecDewatering is a process that separates liquidsolid mixtures, such as slurries comprised of particles and process water, that are present in aggregate, minerals, coal and frac sand wet processing applications Dewatering most often occurs through processes such as wet classification, centrifugation, filtration or similar liquidsolid separation McLanahan Dewatering

Minerals Free FullText Dry Permanent Magnetic Separator

2022年9月9日 Dry permanent magnetic separators have been widely used in the mineral and coal processing industries due to their simple operation and high separation efficiency These tools not only discard some amount of bulk gangue from the raw ore, thereby reducing the volume of the grinding operation and cutting energy consumption, but also Multotecdesigned spiral concentrators are used across the world in coal, gold, iron ore, mineral sands, platinum and chrome processing plants as part of the beneficiation process and separates ore and material between 38 and 2 000 microns As a turnkey supplier of gravity concentration equipment across the world, Multotec delivers endtoend Spiral Concentrator Multotec2015年4月15日 The traditional acid–base separation method can cause serious environmental problems In this research, imidazole and its homolog compounds were designed as new extraction agents for the separation of phenols from coal tar, which can form deep eutectic solvent with phenols with the removal efficiencies more than 90%The new liquid–liquid extraction method for separation of