عنا

مرحبا هل يمكنني مساعدتك؟

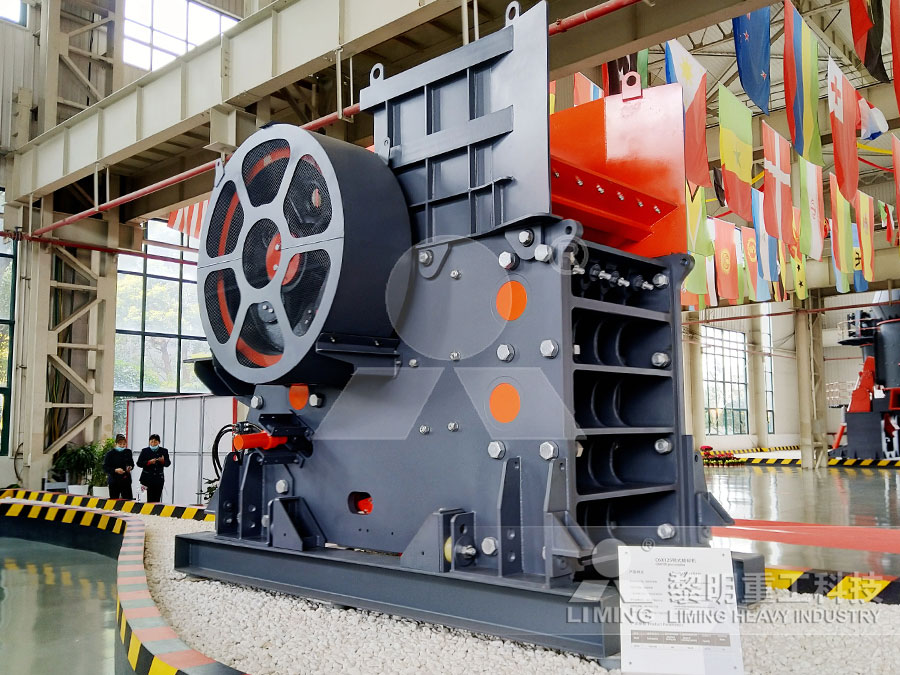

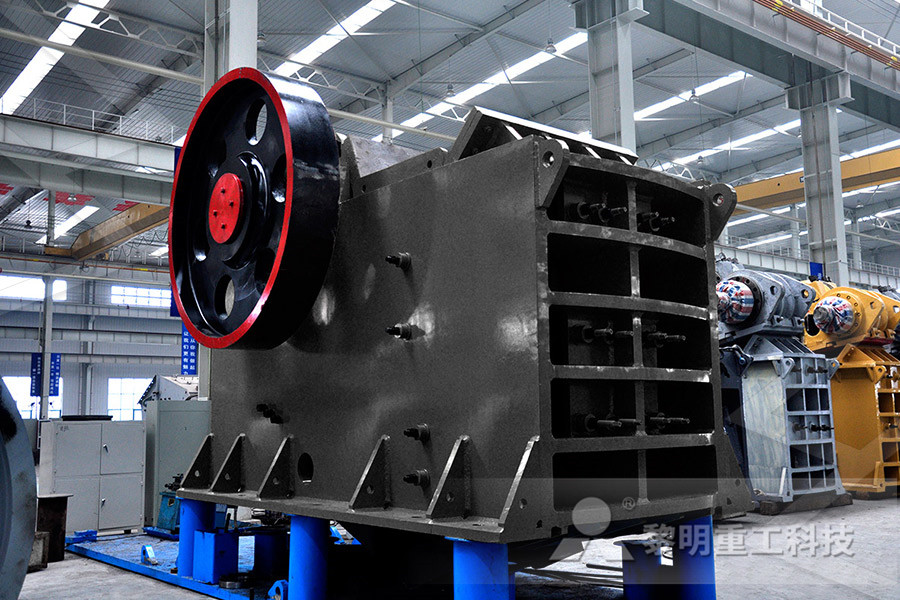

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

are the component of stone crusher

2023-12-09T07:12:02+00:00

A Comprehensive Guide to Stone Crusher

2023年2月22日 Components of Stone Crusher Machines Stone crusher machines are made up of several components that work together to crush large rocks and stones into smaller, usable pieces Some of the most 2019年5月31日 The main objective is to design impact stone crusher Impact stone crusher involves the use of impact rather than pressure to (PDF) Design of Impact stone crusher machine2022年5月13日 2 Concept of Stone Crusher Stone Crusher is a sort of pulverizer which is utilized to compress or break out Stone Crushers: A Technical Review on Significant Part of

CRUSHER MAIN COMPONENTS Crusher Mills, Cone Crusher

main components of a rock crusher for gold mining Jaw Crusher Components,Major Stone and Rock Crusher Components Jaw Crusher components are constituted by About Us Blog Contact 5 Types Of Stone Crushers Leave a Comment/ Jaw Crusher/ By sales@jxscmine Stone crusheris mainly used for crushing operation in quarry crushing plant and mining plant There are 5 types of 5 Types Of Stone Crushers Application and 2021年9月22日 Most sand and gravel plants usually adopt a twostage oneclosedcircuit process, that is, the secondstage crusher and the inspection and screening equipment What are the Main Equipment Components of the Stone

Stone crusher plant design Henan Deya Machinery Co, Ltd

2022年4月19日 Sand and gravels are the basic construction materials, the common raw materials for a stone crusher plant includes cobblestone, granite, basalt, gabbro, 2023年7月1日 Components and Features Each crusher is a symphony of components working in unison to break down rocks In a jaw crusher, for instance, you will find a pair of vertical jaws—an immobile one and a From Quarry To Construction: Understanding The 2021年4月19日 Pada dasarnya kita dapat mendesain stone crusher plant sesuai dengan kapasitas yang kita inginkan Umumnya kita dapat membuat stone crusher plant dengan kapasitas 50 TPH hingga 600 TPH (Ton Per Mengenal Stone Crusher Plant Secara Mendalam –

Forces in a Cone Crusher SpringerLink

2019年3月21日 The crusher will be most effective when the mobile cone rotates around its axis In that case, force Fro acts on the piece, creating an internal torque Such behavior is feasible within a cone crusher with parallel axes of the crusher and the mobile cone, if the mobile cone is rigidly attached to its shaft2020年1月1日 The small scale granite stone crusher was designed to crush stones of approximately 25135mm to about 24202mm in size SOLID WORKS was used as a stress analysis tool on the gear (main crushing part) to determine the regions where the gear experiences maximum force according to VonMisses failure criteriaDesign of a smallscale granite stone crusher ScienceDirectThis paper deals with the design and analysis of the welding fixture for the body of a stone crusher A fixture is a workholding or support device used in the manufacturing industry Fixtures are used to securely locate (position in a specific location or orientation) and support the work, ensuring that all parts produced using the fixture DESIGN AND ANALYSIS OF FIXTURE FOR A STONE CRUSHER

A Guide to Mobile Crushing Plants: Types, Components

2023年2月24日 Crusher: The crusher is the main component of the mobile crushing plant It crushes the material into smaller pieces, reducing them to a size that can be transported by conveyors or other means Conveyor: The conveyor is used to transport the crushed material to a designated area for further processing or stockpiling2023年2月7日 Aggregate and Crusher Dust as road component materials Gradation mixes were prepared to Crushed stone aggregate was obtained from nearby stone crusher plants of Visakhapatnam After brushing the aggregate it was washed and dried A set of sieves such as 53mm, 265mm, 95mm etc have identified for the gradation of stone A STUDY ON THE USE OF CRUSHED STONE AGGREGATE 2023年2月22日 The following are some of the types of cone crusher parts: Mainshaft and head center: The mainshaft is a rotating component that connects the mantle to the motor The head center is a stationary part that supports the mantle and distributes the crushing forces These components are critical for the proper functioning of the cone crusherUnderstanding Cone Crusher Parts Names, Functions, and

Crushers All crusher types for your reduction needs

All crusher types with 100+ years of experience Our crushers are fit for aggregates production, construction material recycling and mining operations Menu Close VSI crusher can be considered a ‘stone pump’ that operates like a centrifugal pump The material is fed through the center of the rotor, where it is accelerated to high speed WHAT ARE THE MAIN COMPONENTS OF JAW CRUSHERS? / PARTS AND MAIN PARAMETERS OF JAW CRUSHERS Jaw crushers are generally defined by their opening size For example, a 900x650 mm crusher refers to a crusher with an inlet measuring 900 mm by 650 mm The main parts and main technical parameters of a jaw crusher are What Is A Jaw Crusher MEKA2019年5月31日 The fabricated stone crusher was tested and the actual capacity was found to be 301 kg/h with a throughput efficiency of 754 % The crushed products were well graded with 189 coefficient of (PDF) Design of Impact stone crusher machine ResearchGate

Cone Crusher Parts 911 Metallurgist

2017年2月19日 Cone Crusher MAINSHAFT The mainshaft is of high grade forged steel, annealed for stress relief It is tapered to gauge for head center fit The bottom of the shaft is fitted with a polished bronze step 2019年8月24日 Components of jaw crusher In this machine, various parts (components) are interlinked together by bolting, welding and trapping (confining) to build a functioning Jaw crusher Most of these components are discussed below Moveable jaw stock The moveable jaw stock is the main moving part in a jaw crusherDesign and Construction of Rock Crushing Machine from 2022年4月19日 In the stone crusher plant processing, the appropriate stone crusher should be chosen based on the different raw materials First of all, when we categorize the raw materials, we can roughly divide the raw materials into hard stone and soft stone Hard stone typically includes cobblestone, granite, basalt, whose hardness is basically above 150MpaStone crusher plant design Henan Deya Machinery Co, Ltd

Stone Crushing Plant Factory Price 301000 TPH Aimix

Stone crushing plant is a key equipment to crush, screen, and classify the large chunk of raw granite, raw basalt, raw ore, raw quarze, construction waste, and other raw materials into specific sizes, such as 05mm, 5010mm, 1020mm, 2030mm, and 3040mm Stone crushing plants are widely used for mining, quarry, metallurgical and chemical industries, 2023年11月3日 2Year / 6,000 Hour Superior crushers come backed by a rocksolid 2year / 6,000hour warranty against manufacturer defects Superior manufactures fifteen Americanmade models, which are gaining a strong reputation Connect with one of our crushing experts and find the right machineCrushing Equipment Superior Industries US ManufacturerThe roller crushers are used for moist and sticky materials Generally the machines have to be rigid enough to crush also hard inclusions As the reduction ratio is only about 5:1 a 2stage crushing is required in most applications Fast running type crushers like hammer and impact crushers are the simplest and cheapest solution, whenever the Everything you need to know about Crushers in Cement

Cone Crushers (Parts of a Cone Crusher) Explained saVRee

Cone Crusher Components (Crusher Parts) The main components of a cone crusher include the main shaft , mantle , concaves , cone , eccentric bushing , drive , crown gear , frame, and tramp release mechanism (mechanically or hydraulically actuated) Cone Crusher Components Top Shell Spider Cap Assembly The feed is fed by conveyors to a feed 2018年8月7日 The design and construction of a prototype rock crushing machine was performed this is with a view to ensuring that the designed crusher is capable of crushing rocks, lime stone and solid minerals (PDF) Design and Construction of Rock Crushing Machine 2022年10月30日 Abstract Stone dust is a waste material obtained from crusher plants It has potential to be used as partial replacement of natural river sand in concrete Use of stone dust in concrete not only improve the quality of concrete but also conserve the natural river sand for future generations In the presentStone Dust in Concrete: Effect on Compressive Strength

How it Works: Crushers, Grinding Mills and Pulverizers

2017年6月2日 Table Source: Wikipedia (Crushers) Cone crushers use a spinning cone that gyrates in the bowl in an eccentric motion to crush the rock between the cone surface, referred to as the mantle, and the crusher bowl linerGyratory crushers are very similar to cone crushers, but have a steeper cone slope and a concave bowl surface As the gap 2023年10月9日 Lubrication and Wear Parts: Proper lubrication is the lifeblood of any stone crusher Regularly greasing the moving parts ensures smooth operation and prolongs the life of wear components such as How Can We Make Full Use Of Stone Crusher in The Quarry?2023年10月20日 Jaw crusher is a heavyduty which crushing the hard rock Therefore, the jaw crusher parts need to be very hard and durable In particular, the two components of the jaw crusher work, the fixed jaw, Types of Stone Crushers Machine Mineral

Effect of Size and Gradation of Crusher Stone and

2023年1月20日 soils in the component layers of the flexible pavements To meet the requirements of MORTH and IRC specifications crusher dust and crushed stone have been chosen as flexible pavement materials Crusher dust is a waste product obtained from stone crusher plants with annual production of 23 Lakh tonnes a Silt (%) bSize Reduction) A crusher is a machine designed to reduce the size of large rocks to smaller rocks, gravel, sand, or rock dust; this is essential for efficient transport of the product via conveyors etc Crushing is the first of many stages that lead to separation of the mineral(s) from the waste (gangue) materialWaste material can be discarded or recycled allowing Jaw Crusher Explained saVRee2023年9月15日 A stone crusher typically consists of several main components and spare parts that may need replacement or maintenance over time These spare parts and components can vary depending on the type What are the spare parts of a stone crusher? LinkedIn

Design of a crushing system that improves the crushing

2016年2月10日 will result in the jaw crusher producing stones above 30mm diameter which will strain the cone crusher and will result in it breaking down Decreasing the space between jaws will result in the process being extremely slow Therefore a system that is faster and produces smaller diameter stones of less than 12mm diameter is required 3New generation Roll Crusher has been designed using latest engineering tools for high reliability It has premium features like highefficiency gear drive and hydraulic gap management Crushers are machines that use a rigid surface to compress and break large rocks into smaller rocks Offers highest crushing efficiency with lowest cost per Crusher Machine Manufacturer Propel Industries2023年3月14日 In conclusion, crushing machinery is an essential component of stone crushing plants Different types of crushing machinery are used depending on the type and size of the raw material being crushing machinery for stone crushing plants LinkedIn

The Complete Guide to Crushed Stone and Gravel GraRock

2019年11月11日 Crushed stone often has an angular and jagged edge because of the crushing process Gravel, on the other hand, typically has a very smooth texture and surface because of the natural weathering and wear of being exposed to running water Unlike crushed stone, gravel is usually sold and used in its natural stateThe screens are the most fragile component of the mill; the cost of grinding stone with the Amtech mill is reduced from 248 CFA/kg to an estimated 147 CFA Grinding Mill Component List Crusher Mills, Cone Crusher Components Of A Grinding Mill Crusher Mills, Cone CrusherSee Full PDFDownload PDF International Journal of Scientific Engineering Research Volume 10, Issue 5, May2019 904 ISSN 22295518 Design of impact stone crusher machine Tesfaye O Terefe, Getaw A Tefera Abstract: Crushers are one of the main equipment used for reducing size in metallurgical, mechanical, and other similar industries(PDF) Design of Impact Stone crusher machine Academia

Jaw crusher parts

Jaw design for your application Jaw crusher wear parts are designed for processing all rock types in surface and underground operations Our offering consists of jaw plates such as different onepiece jaws and twopiece jaws as well as cheek plates Due to the wide range of applications and feed materials, our jaws are available in several different designs and 2023年10月10日 Here are some key features and components of a typical mobile stone crusher: Mobile stone crushers come in various types and configurations to suit different applications and job requirements The Types of stone crusher? how many types of stone crushing2020年5月20日 We’re experts at navigating all of the different components of rock crusher selection, setup, and maintenance If you’re looking for guidance into selecting and servicing a machine that will be the best fit possible, get in touch with us today online or The Top Rock Crusher Brands Mellott

How Impact Crushers Work: A Comprehensive Guide AGICO

2023年3月11日 The components of an impact crusher An impact crusher consists of several components, including the rotor, hammers, impact aprons, and screens The rotor is the central part of the machine, and it is the part that rotates and drives the hammers 450t/h Stone Mobile Crushing Plant; 320t/h Construction Waste Material Crushing 2021年7月26日 MECHANICAL DESIGNOF A SMALL SCALE MECHANIZED STONE CRUSHER A final year project for the partial fulfillment for the award of bachelor’s degree in Mechanical and Manufacturing Engineering of the University of Nairobi PROJECT SUPERVISOR: PROF FRANK MOSES ODUORI 23 JAW CRUSHER Small Scale Mechanized Stone Crusher, Mechanical DesignIn particular, the two components of the jaw crusher work, the fixed jaw, and the movable jaw The crushers machine are widely used in industries of mining, building materials, roads, railways, water conservancy, and chemical The types of jaw stone crusher: single toggle jaw crusher and double toggle jaw crusher Routine Maintenance5 Types Of Stone Crushers Application and Maintenance JXSC Rock Crusher

Crushed Stone Machines: The Key to HighQuality Building

2023年2月24日 Crushed stone machines play a critical role in the construction industry by crushing large rocks into smaller, more manageable pieces that can be used in a variety of building projects In this comprehensive guide, we explore the different types of crushed stone machines, their components, and how to operate them safely and efficiently We In 1883 Mr Blake challenged Mr Gates to crush 9 cubic yards of stone in a contest to see which crusher would finish the job faster The Gates crusher completed the task 40 minutes sooner! The Gates’ gyratory crushers were preferred by the mining industry for almost two decades until the turn of the century, circa 1910, when Blake’s jaw Types of Crushers: What You Need to Know Machinery 2021年6月24日 the crusher and scalp out fi nes Primary gyratory crushers – ideally suited to all highcapacity primary hard rock crushing applications Jaw crushers – we have more installed jaw crushers than anyone in the world The leading choice due to their high reduction ratio and heavy duty design Cone crushers – capacities available to suit allCrushing and Screening Handbook AusIMM

Forces in a Cone Crusher SpringerLink

2019年3月21日 The crusher will be most effective when the mobile cone rotates around its axis In that case, force Fro acts on the piece, creating an internal torque Such behavior is feasible within a cone crusher with parallel axes of the crusher and the mobile cone, if the mobile cone is rigidly attached to its shaft2020年1月1日 The small scale granite stone crusher was designed to crush stones of approximately 25135mm to about 24202mm in size SOLID WORKS was used as a stress analysis tool on the gear (main crushing part) to determine the regions where the gear experiences maximum force according to VonMisses failure criteriaDesign of a smallscale granite stone crusher ScienceDirectThis paper deals with the design and analysis of the welding fixture for the body of a stone crusher A fixture is a workholding or support device used in the manufacturing industry Fixtures are used to securely locate (position in a specific location or orientation) and support the work, ensuring that all parts produced using the fixture DESIGN AND ANALYSIS OF FIXTURE FOR A STONE CRUSHER

A Guide to Mobile Crushing Plants: Types, Components

2023年2月24日 Crusher: The crusher is the main component of the mobile crushing plant It crushes the material into smaller pieces, reducing them to a size that can be transported by conveyors or other means Conveyor: The conveyor is used to transport the crushed material to a designated area for further processing or stockpiling2023年2月7日 Aggregate and Crusher Dust as road component materials Gradation mixes were prepared to Crushed stone aggregate was obtained from nearby stone crusher plants of Visakhapatnam After brushing the aggregate it was washed and dried A set of sieves such as 53mm, 265mm, 95mm etc have identified for the gradation of stone A STUDY ON THE USE OF CRUSHED STONE AGGREGATE 2023年2月22日 The following are some of the types of cone crusher parts: Mainshaft and head center: The mainshaft is a rotating component that connects the mantle to the motor The head center is a stationary part that supports the mantle and distributes the crushing forces These components are critical for the proper functioning of the cone crusherUnderstanding Cone Crusher Parts Names, Functions, and

Crushers All crusher types for your reduction needs

All crusher types with 100+ years of experience Our crushers are fit for aggregates production, construction material recycling and mining operations Menu Close VSI crusher can be considered a ‘stone pump’ that operates like a centrifugal pump The material is fed through the center of the rotor, where it is accelerated to high speed WHAT ARE THE MAIN COMPONENTS OF JAW CRUSHERS? / PARTS AND MAIN PARAMETERS OF JAW CRUSHERS Jaw crushers are generally defined by their opening size For example, a 900x650 mm crusher refers to a crusher with an inlet measuring 900 mm by 650 mm The main parts and main technical parameters of a jaw crusher are What Is A Jaw Crusher MEKA2019年5月31日 The fabricated stone crusher was tested and the actual capacity was found to be 301 kg/h with a throughput efficiency of 754 % The crushed products were well graded with 189 coefficient of (PDF) Design of Impact stone crusher machine ResearchGate