عنا

مرحبا هل يمكنني مساعدتك؟

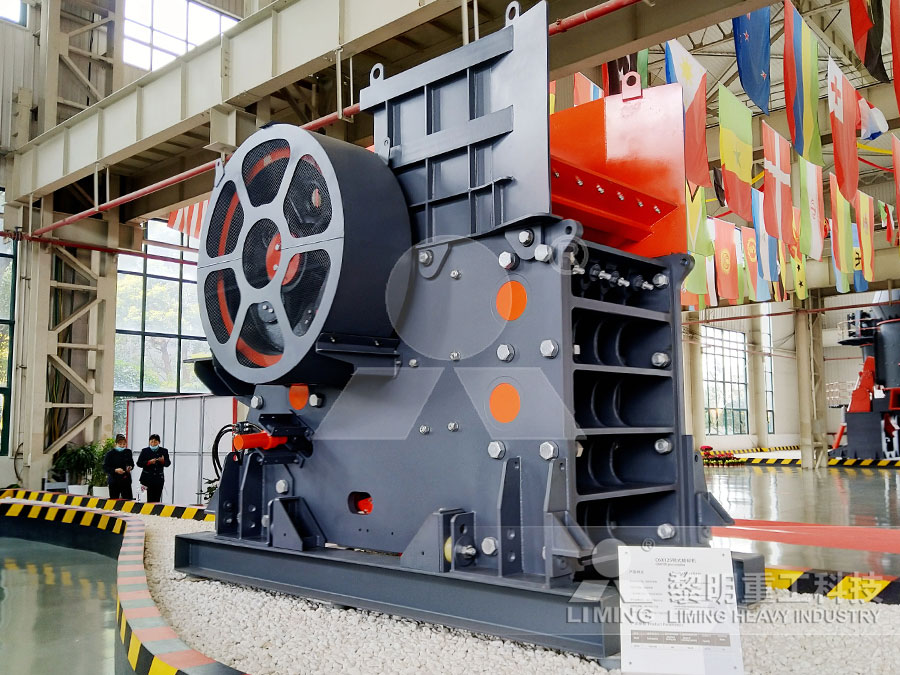

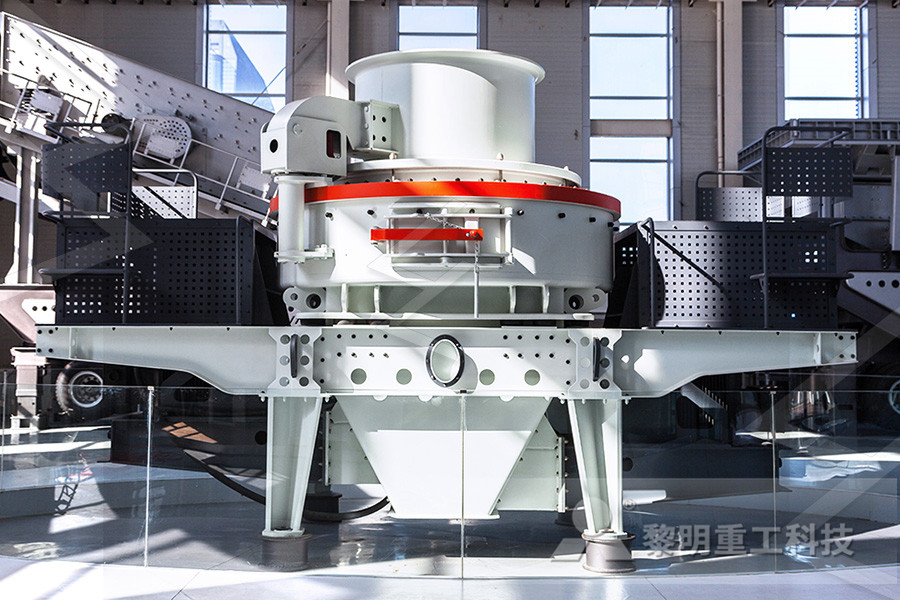

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

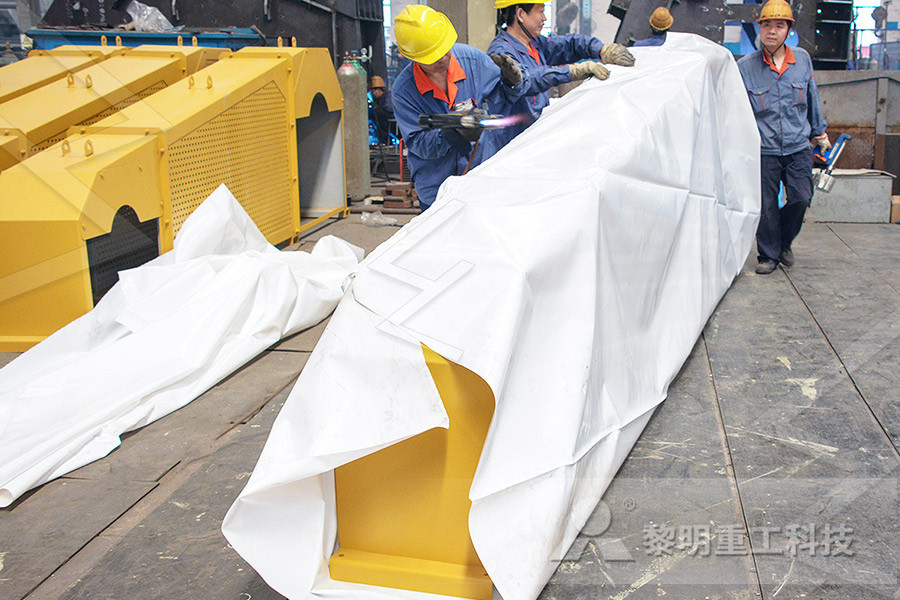

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

vertical shaft impact crusher parts time

2023-12-19T01:12:32+00:00

Vertical Shaft Impact Crusher China First Engineering

2023年9月27日 Vertical shaft impact crusher is widely used in crushing and reshaping of rock and artificial sand making It is suitable for crushing of fragile materials below level 9 of Moh’s hardness rather than viscous materials or stone materials containing much so 2020年4月14日 VERTICAL SHAFT IMPACT CRUSHERS (VSI) TECHNICAL SPECIFICATION CV200 RANGE VSI CRUSHER OPERATIONAL FLEXIBILITY SANDVIK CV200 RANGE VERTICAL SHAFT IMPACT Durable impact crusher parts last longer and increase throughput Available for both horizontal shaft impact (HSI) crushers and vertical shaft impact (VSI) crushers, 's comprehensive wear and spare parts offering Impact crusher parts

Cemco™ Vertical Shaft Impactor (VSI) Superior Industries

2023年11月3日 The result was the creation of the modern vertical shaft impact (VSI) crusher, a pioneering design that has stood the test of time with the first unit still 2023年11月3日 Offering TopoftheLine Impact Crushers Vertical shaft impact (VSI) crusher is widely used for quaternary, tertiary, and secondary applications of crushing rock, cement clinker, quartzite, and concrete Vertical Shaft Impact Crusher AF Minerals 2 天之前 The efficient and versatile design of the Astec vertical shaft impactors (VSI) delivers highly consistent end products for jobs that demand precision Astec VSI Vertical Shaft Impactors Astec

Vertical Shaft Impactor Crusher Manufacturer Propel

VERTICAL SHAFT IMPACTOR AVVI SERIES Propel Vertical Shaft Impactor has been developed with inputs from aggregate producers The high velocity impact crusher in Spokane provides quality wear parts for some of the worlds leading Vertical Shaft Impactor manufacturers such as Barmac, Canica, Cedarapids, Cemco, ISC, KolbergPioneer, Remco, Spokane, , Texas Crusher, Impact Crushers Spokane IndustriesSPLASH Vertical Shaft Impact Crushers, Model No: FC and GC series ₹ 6,00,000 Get Latest Price Brand: SPLASH Usage/Application: Primary and Secondary Hard rock crushing, Mixed Demolition debris, Crushed or Vertical Shaft Impact Crusher Vertical Crusher

Trio® Crushing Equipment Weir

Our range of Trio® horizontal shaft impactors (or "horizontal impact crushers") are engineered for the most rugged and demanding applications They have been developed for a variety of primary and secondary applications within the aggregate, recycling and industrial industries These crushers produce highquality aggregates at a high New Pilot Crushtec VS350 VSI Crusher The VS350 is a skid mounted vertical shaft impact crusher for use in tertiary and quaternary crushing applications It is a versat Priced From $303,440 Ex GST VIC Delivers Nationally View Listing SAVE $28,000 11 Used SMA623CT IMPACTORNew or Used Impact Crusher for sale Australia Machines4uSandvik Vertical Shaft Impact (VSI) Crushers Throughout our VSI crusher range, we have put the time into what needs to be focused on and what will give you maximum performance when using them This process ensures we can design VSI crushers that cost less to run and increase profitability Designed with high capacity and low power consumption Stationary VSI impact crushers, Sandvik VSI Crusher Brochure

Auspactor™ VSI HE Parts International

HE Parts manufacture and supply the Auspactor™ Range of vertical shaft impact (VSI) crushers to global markets The innovative design of the Auspactor™ VSI is based on years of experience and field trials It provides easier and fewer tip and part changes resulting in lower running costs With the unique design and flexibility of the 2021年12月1日 A geometric model of rotors is established on the basis of the structure of vertical shaft impact crusher The dynamic simulation of the rotor is carried out by using the discrete element software EDEM At the same time, the correlation between the angle of the guide plate and the crushing performance of the crusher is studied systematically The Correlation between the Angle of the Guide Plate and 2008年8月1日 Abstract The vertical shaft impact (VSI) crusher is a commonlyused machine in aggregate production A comprehensive understanding of the physical phenomena that influence the power consumption and the particle output of the device are essential to enable development of protocols that minimize energy consumption during Modelling of output and power consumption in vertical shaft impact

Canica Vertical Shaft Impactors MPS

2023年11月3日 Canica® provides a comprehensive range of vertical shaft impactors to customers around the world Our equipment is designed to produce the highest quality end products We provide Modular, Portable and Static VSI plants and components – plus full parts, service and maintenance with support you can count on, wherever you are We Propel Vertical Shaft Impactor produces shapes as per the Ministry of Road Transport Highways (MORTH) standards Crusher impact combined with speed gives the unique shape resulting in production of highquality manufactured sand confirming to C Vertical Shaft Impactor Crusher Manufacturer Propel2015年4月1日 Vertical Impact Crusher In the hammer mill, a high speed impactor generates collisions with slowly moving feed An alternative arrangement is to generate streams of high speed feed particles and have them collide with stationary surfaces One such class of crusher is called a vertical shaft impactor (VSI) Fig 16 shows a CAD Simulation of particle flows and breakage in crushers using DEM: Part

Numerical Simulation of a Single and DoubleRotor Impact Crusher

2021年11月12日 Cunha et al investigated the distribution of collision energies and the residence time distribution in the same vertical shaft Cleary, PW Simulation of particle flows and breakage in crushers using DEM: Part 2–Impact crushers Tavares, LM Simulation of solids flow and energy transfer in a vertical shaft impact crusher using The Leader in Vertical Shaft Impactor Wear Parts As the manufacturer of the original Spokane Crusher, Spokane has over 40 years of experience in Vertical Shaft Impactor Wear Parts Spokane provides wear parts in Impact Crushers Spokane IndustriesThe three types of crushers most commonly used for crushing CDW materials are the jaw crusher, the impact crusher and the gyratory crusher (Figure 44)A jaw crusher consists of two plates, with one oscillating back and forth against the other at a fixed angle (Figure 44(a)) and it is the most widely used in primary crushing stages (Behera et al, 2014)Impact Crusher an overview ScienceDirect Topics

4 Types of Stone Crushers' Maintenance and

2023年2月15日 Replace badly wearing parts in time Regularly inspect temperature of the rotor, motor and bearing, etc Sanding making machine Sand making machine The sand making machine is also known as the VSI Crushing Method The VSI is typically used after a primary or secondary crusher This makes a VSI ideal for making sand and for making coarse and medium aggregates for concrete/asphalt production Feed size and characteristics will affect the application of a VSI The feed size is limited by the opening in the center of the rotorWhat Is A Vertical Shaft Impactor (VSI) Primer? Stedman 2020年4月14日 VERTICAL SHAFT IMPACT CRUSHER RETROFITTING Upgrading with a Top Half Retrofit reduces power consumption, increases crusher throughput, requires fewer wear parts, and reduces vibration levels, all to ensure greater uptime Our patented VSI rotors fit easily into most major crushers Wear parts are small and easily manageable CRUSHES PERFECT PRODUCT SQUEEZES YOUR COSTS

VERTICAL SHAFT IMPACT CRUSHERS

2022年6月26日 WHAT IS TERTIARY IMPACT CRUSHER? Meka Top Tertiary Impact crusher manufacturer Best Tertiary Impact crusher Fehmi Soner Mazlum VERTICAL SHAFT IMPACT CRUSHERS (VSI) MEKA CRUSHING SCREENING AND CONCRETE BATCHING TECHNOLOGIES mekaglobal MEKA IS A PROFESSIONAL SOLUTION Meka 2 天之前 The efficient and versatile design of the Astec vertical shaft impactors (VSI) delivers highly consistent end products for jobs that demand precision Astec VSI crushers are available in both stationary and portable configurations and produce up to 500 tons per hour With the ability to run in standard, semiautogenous and fully autogenous Vertical Shaft Impactors Astec2013年4月1日 Three crusher types are used to demonstrate these capabilities: 1 Twin roll crusher 2 Cone crusher 3 Vertical Shaft Impactor (VSI) These show the nature and level of fidelity that is now possible to include in particle scale crusher models including breakage of nonspherical particles and prediction of the product size distribution and Simulation of solids flow and energy transfer in a vertical shaft

Our Range of Trio® Vertical Shaft Impactor Crushers Weir

Engineered to produce highquality, wellshaped particles and fine aggregates, our range of Trio® vertical shaft impactors (or "vertical impact crushers") use innovative technology to deliver outstanding performance in secondary, tertiary and quaternary crushing applications The enhanced versatility of the Trio® TV Series vertical shaft impactor means that it can Note: Extra GST applicable View Complete details Get Best Quote Request A Callback Manufacturer of Impact Crusher Cast Iron HSI Impact Crushers 100TPH, V 50 Sand Maker, Deepa Horizontal Shaft Impact Crusher 100 Tph and Vertical Shaft Impact Crusher100TPH offered by Deepa Machinery Manufacturers Private Limited, Impact Crusher Cast Iron HSI Impact Crushers 100TPH 2020年4月14日 VERTICAL SHAFT IMPACT CRUSHERS (VSI) CV200 RANGE VSI CRUSHER rotor wear part failure Optimum operation of the crusher (lowest possible cost per ton), is always achieved when operating the crusher crusher range, can be realized when the following parameters have been selected: • Maximum motor size for SANDVIK CV200 RANGE VERTICAL SHAFT IMPACT

Crushing 101 – Different types of crushers for

2020年12月17日 Jaw crushers can be divided into two basic types, single and double toggle In the single toggle jaw crusher, an eccentric shaft is on the top of the crusher Shaft rotation, along with the toggle plate, causes 2023年9月27日 A vertical shaft impact crusher has two operating modes: rocktosteel and rocktorock Rocks are accelerated by a quickly rotating rotor They are then broken into pieces in the crushing chamber Load and wear experiments on the impact hammer of a The new Patented Tubular Rotor provides many benefits over the standard shoe and anvil designs as well as rockshelf applications The easily replaceable and indexable rotor tubes, cut your total operating cost and maintenance time in half, making VSlam the easiest VSI crusher to maintain and one of the best impact crushers on the marketVertical Shaft Impactors VSI Crushers Stedman Machine

Horizontal Vertical shaft Impact Crushers Moore Watson Ltd

The PFR series of Impact crushers are a perfect combination of heavy duty rotor, high wearresistant materials which are incorporated in the complete high quality, steel fabricated crusher frame and chamber design This combination has proven to be extremely successful over a long period of time, not only increasing productivity and product quality but also 2023年7月14日 • Multiple internal crusher configuration options • Pinion gear drive option for models 2050 through 2500 • Fully equipped test crushing facility • Reliable parts and service from experienced dealer organization • 3 year crusher warranty Vertical Shaft Impactor Benefits The ® Canica VSI Advantage • Very cubicle product Canica VSI VERTICAL SHAFT IMPACT CRUSHERS2015年10月28日 Verticalshaft impact (VSI) crushers Generally recognized as tertiary crushers, verticalshaft impact crushers have material fed into the centre of the crusher, through a feed tube, and on to the centre of a rotating table or rotor The material is then accelerated to high velocity and thrown into the anvil ring or outer shellSelecting the Right Crushing Equipment AggNet

Optimal Energy Control Modelling of a Vertical Shaft Impact

2014年1月1日 This paper presents an optimal control model to improve the operation efficiency of a vertical shaft impact (VSI) crushing process The optimal control model takes the energy cost as the performance index to be minimized by accounting for the timeofuse (TOU) tariff The control variables in the developed model are the belt conveyor feed flow The higher the abrasion, hardness, and finescontent the faster the wear The rotor body holds hammers in place through a sliding system (see picture) or they are lifted in and wedged in place Learn more about hammers Impact Crusher Models RUBBLE MASTER offers a large range of mobile Impact Crushers ranging from 90 to 385 TPHHow does an impact crusher work? RUBBLE MASTER2017年9月1日 The Andersen/Awachie/Whiten model of the cone crusher has been applied in modeling the performance of a 264 kW vertical shaft impact crusher producing manufactured sand Part 2 – impact crushers Miner Eng, 74 (2015), pp 163177 View PDF View article View in Scopus Google Scholar Whiten, 1972Mathematical modeling of a vertical shaft impact crusher using

China High Manganese Casting Parts Manufacturer, Hihg

Peak Season Lead Time: Impact Crusher Wear Parts manufacturer / supplier in China, offering Durable Cone Crusher Wear Parts Made of High Manganese Steel for Gp11f Bowl Liner Mantler and Concave, Gp11f Bowl Liner Mantler and Concave for High Manganese Cone Crusher Wear Parts, VSI Crusher of B9100 UpperLower Wear Plate for Heavy A system and method for monitoring a vertical shaft impact crusher comprises a plurality of sensors which continuously monitor the current status of a plurality of crusher component parts, a computer in communication with the sensors, and a graphical user interface in communication with the computer and on which is displayed a plurality of virtual USB2 System and method for monitoring a vertical shaft impact Vertical shaft impact (VSI) crushers, on the other hand, are used in the last stage of the crushing process, especially when its required that the end product has a precise cubical shape Crusher parts and services Crusher spare parts Spare parts for gyratory, jaw, cone and impact crushers for the mining and aggregates industry Crushers All crusher types for your reduction needs

Tungsten Carbide Wear Parts KoneCarbide

Wear parts play an important role in machinery KoneCarbide manufactures highquality wear parts made from tungsten carbide, featuring high heat, corrosion, and wear resistance, thus improving the service life of machinery Vertical Shaft Impact Crusher (VSI) Rotor and Wear Parts Forestry Teeth Decanter Centrifuge Wear Parts HPGR Studs 2015年6月23日 Impact Crusher Working Principle Impact crushing crushing grinding method Shear crushing is accomplished by breaking along or across lines of cleavage It is possible, when required, for a crusher to use a combination of two or three of these principles The selection or sizing of a crusher is much helped by measuring the rock’s Impact Crusher Working Principle 911 MetallurgistThe VS350 is a skid mounted vertical shaft impact crusher for use in tertiary and quaternary crushing applications It is a versatile crusher primarily used for producing sand and fines and quality enhancement of aggregates Maximum Feed Size Up to 120mm (Dependant on rotor option) Rotor Diameter 1000mmCrushing Screening Equipment Australia Quarrying Mining

Valor® Vertical Shaft Impactor (VSI) Superior Industries

2023年11月3日 Produce Uniform, RoadBuilding Material Compared to compression crushers (jaws and cones), impact crushers – like the Valor Vertical Shaft Impactor (VSI) – process a wider range of material at higher tonnages and allow for more customization of rock shape and size Our Valor VSI offers significant application flexibility because of 2023年7月17日 Raw material: Waste concrete, bricks Feeding size: ≦400 mm Configuration type: Stationary Estimated investment: USD 35,000 to USD 63,000 The equipment has been in use for more than a year According to customer feedback, the impact crusher still runs well, which brings them huge benefitsImpact Crusher With Various Models Fote Machinery2020年2月11日 Time Graph Speed MPS [FPS] 1 Second 110 [361] 100 [328] 90 [295] 80 [262] 70 [230] 60 [197] 50 [164] 40 [131] that the impact crusher used have a wide operating material types and feed gradings REMco vertical shaft impact crushers have the broadest operating range of all VSI crushers Please refer to the rotor velocity scale RockMax SandMax VSI Crushers REMco

Development and testing of a novel mathematical

2021年8月15日 Vertical shaft impact crusher (VSI) is amongst the most utilized comminution machines in the aggregate industries because of it is capacity to produce a large amount of fines with a highquality shape (cubical shape) Ring armor is the main component in VSI in terms of operational efficiency and feature of productsOur range of Trio® horizontal shaft impactors (or "horizontal impact crushers") are engineered for the most rugged and demanding applications They have been developed for a variety of primary and secondary applications within the aggregate, recycling and industrial industries These crushers produce highquality aggregates at a high Trio® Crushing Equipment WeirNew Pilot Crushtec VS350 VSI Crusher The VS350 is a skid mounted vertical shaft impact crusher for use in tertiary and quaternary crushing applications It is a versat Priced From $303,440 Ex GST VIC Delivers Nationally View Listing SAVE $28,000 11 Used SMA623CT IMPACTORNew or Used Impact Crusher for sale Australia Machines4u

Stationary VSI impact crushers, Sandvik VSI Crusher Brochure

Sandvik Vertical Shaft Impact (VSI) Crushers Throughout our VSI crusher range, we have put the time into what needs to be focused on and what will give you maximum performance when using them This process ensures we can design VSI crushers that cost less to run and increase profitability Designed with high capacity and low power consumption HE Parts manufacture and supply the Auspactor™ Range of vertical shaft impact (VSI) crushers to global markets The innovative design of the Auspactor™ VSI is based on years of experience and field trials It provides easier and fewer tip and part changes resulting in lower running costs With the unique design and flexibility of the Auspactor™ VSI HE Parts International2021年12月1日 A geometric model of rotors is established on the basis of the structure of vertical shaft impact crusher The dynamic simulation of the rotor is carried out by using the discrete element software EDEM At the same time, the correlation between the angle of the guide plate and the crushing performance of the crusher is studied systematically The Correlation between the Angle of the Guide Plate and

Modelling of output and power consumption in vertical shaft impact

2008年8月1日 Abstract The vertical shaft impact (VSI) crusher is a commonlyused machine in aggregate production A comprehensive understanding of the physical phenomena that influence the power consumption and the particle output of the device are essential to enable development of protocols that minimize energy consumption during 2023年11月3日 Canica® provides a comprehensive range of vertical shaft impactors to customers around the world Our equipment is designed to produce the highest quality end products We provide Modular, Portable and Static VSI plants and components – plus full parts, service and maintenance with support you can count on, wherever you are We Canica Vertical Shaft Impactors MPSPropel Vertical Shaft Impactor produces shapes as per the Ministry of Road Transport Highways (MORTH) standards Crusher impact combined with speed gives the unique shape resulting in production of highquality manufactured sand confirming to C Vertical Shaft Impactor Crusher Manufacturer Propel

Simulation of particle flows and breakage in crushers using DEM: Part

2015年4月1日 Vertical Impact Crusher In the hammer mill, a high speed impactor generates collisions with slowly moving feed An alternative arrangement is to generate streams of high speed feed particles and have them collide with stationary surfaces One such class of crusher is called a vertical shaft impactor (VSI) Fig 16 shows a CAD 2021年11月12日 Cunha et al investigated the distribution of collision energies and the residence time distribution in the same vertical shaft Cleary, PW Simulation of particle flows and breakage in crushers using DEM: Part 2–Impact crushers Tavares, LM Simulation of solids flow and energy transfer in a vertical shaft impact crusher using Numerical Simulation of a Single and DoubleRotor Impact Crusher