عنا

مرحبا هل يمكنني مساعدتك؟

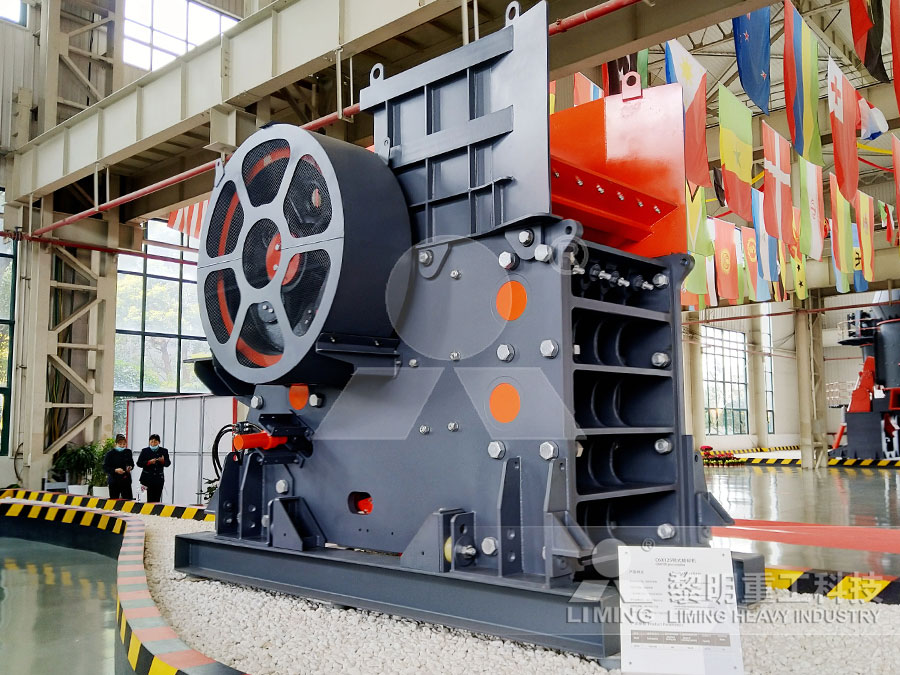

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

energy requirements for a rock crusher

2021-01-12T18:01:20+00:00

ROCK CRUSHING PLANT APPLICATIONS ADVICE

2020年3月28日 In general, a rock crushing plant will have a primary crusher, primary screen, secondary crusher(s) and secondary screen(s), and associated conveyors and stockpiles It may also involve portable generators powered by diesel engines Emissions 2021年10月30日 Many publications such as Langefors and Kihlström and Revnivtsev stated that the energy efficiency of rock blasting was in the range of 5–15% However, Energy Requirement for Rock Breakage in Laboratory2015年12月16日 The approximate capacity of a jaw crusher for hard rock application at a typical setting may be obtained by multiplying the width by 10 to get tonnes per hour For Rock Crushing Rule of Thumb 911 Metallurgist

Energy considerations in compressive and impact crushing of rock

2008年8月1日 A comparison of capacity, size reduction and power draw shows that the VSI crusher is significantly more energy efficient than the cone crusher, and it produces 2015年7月18日 First the rock will enter the crushing chamber and drop as far as the angle of the crushing surface will allow it to The crusher “breaks it and the fine material produced will drop through the gap between the Rock Crushing Process in Mining 911 Metallurgist2013年11月8日 932 Energy Requirements Major energy sources for limestone and other crushed rock include fuel oil and purchased electricity In 1992, rock mining consumed Limestone and Crushed Rock Department of Energy

Influence of Operating Conditions and Crushing Chamber on Energy

2018年5月1日 The total energy consumption in a cone crusher can be divided into several parts: noload mechanical energy of the cone crusher, energy consumption during 2013年6月20日 Capacity And Energy Required Of A Primary Crusher In Nigeria energy requirements for a rock crusher MINING SOLUTIONS Primary crusher capacity and Capacity And Energy Required Of A Primary Crusher Crusher 2022年1月23日 The work indices are important for determination of crushing energy requirements and the abrasion index is important for estimating equipment metal wear and grinding media consumption The hardness according to Mohs scale of Gibbsitic and Boehmitic bauxites are typically 1–3, while it ranges from 6½–7 for Diasporic bauxites [ 3 ]Physical Bauxite Processing: Crushing and Grinding of Bauxite

4 Types of Stone Crushers' Maintenance and

2023年2月15日 Horizontal Shaft Impact crusher (HSI) Impact crusher working animation The working principle of impact crusher is that the spinning rotor under the driving of the motor can genetate strong impact 2020年2月5日 The function ofthe rock crusher system was defined to be crushing glacier round to pieces of1~inchesand below3 The functional unit to which the rock crusher was normalized is 1000 shorttons ofcrushed glacier round rock of1~inchesand below All energy and materials consumed, as well as emissions to the environment, were normalized toLife Cycle Assessment of a Rock Crusher ACEEE2 天之前 This page is about the Crusher added by Immersive Engineering For other uses, see Crusher The Crusher is a 3×5×3 multiblock added by Immersive Engineering It is used for crushing ores into grit, which is more efficient than normal smelting Once the blocks are assembled, use the Engineer's Hammer on the center of the front of the longer side Crusher (Immersive Engineering) Official Feed The Beast Wiki

Modelling energy and size distribution in cone crushers

2019年8月1日 In the piston and die test, the breakage energy is measured and the data is then used for calibrating the energy model This paper aims to show how the particle size distribution and the energy model is modelled for a Sandvik Hydrocone crusher using the work by Evertsson, 2000, Lindqvist, 2005, see Fig 1 The paper will also show validation 2016年1月1日 One study [6], which is a collaboration that compares seven mine mill/concentrator operations: four gold and three iron ore mines The average energy needed for seven mines is summarized in figure 2, where the energy requirement is broken down into six components: crushing, grinding, processing, tailings, process water, plant general Energy Consumption in Mining Comminution ScienceDirect13311 Primary Crusher Primary crushers are heavyduty rugged machines used to crush ROM ore of (−) 15 m size These largesized ores are reduced at the primary crushing stage for an output product dimension of 10–20 cm The Crusher an overview ScienceDirect Topics

(PDF) Cone Crusher Performance ResearchGate

2015年5月13日 geometry, crusher dynamics and rock material characteristics Concave, mantle, eccentricity and location of the pivot point together form the chamber resulting motion of the mantle and main shaft 2023年3月2日 Introduction For the 100tph stone crushing plant, the truck transfers the original stone with input size under 500mm into vibrating feeder 380*96, and it transfers the stones to jaw crusher PE 600*900, after first crushing the material gets 65180mm size, and then it goes to second crushing cone crusher 1200, the output (1640mm) of cone Getting To Know The Complete Set Stone Crushing PlantA continuous equipment development programme ensures minimum wear, maximum availability, very low maintenance requirements and extreme flexibility regarding establishment of machine and product parameters IMPACTORS FOR SECONDARY AND HARD ROCK CRUSHINGIMPACT CRUSHERS

Gyratory crusher (adapted from ThyssenKrupp,

Download scientific diagram — Gyratory crusher (adapted from ThyssenKrupp, 2005) from publication: A Gyratory Crusher Model and Impact Parameters Related to Energy Consumption The objective 2008年8月1日 12 Production challenges in miningIn a typical mining application, a primary crusher reduces the size of blasted rock; from several hundred mm down to 0–250 mm A secondary crusher then reduces the size from those 250 mm down to about 0–70 mm, and is then followed by a tertiary crusher in closed circuit with a screenThe final Energy considerations in compressive and impact crushing of rock1 天前 Typically, the minimum setting on most primary crushers will be about 4 to 6 inches, as noted above Compressionstyle jaw, cone, impact crushers, and gyratory crushers are most often appropriate as primary Types of Rock Crushers Quarry Crushing

Understanding the Different Types of Crushers AggNet

2018年9月10日 Size reduction in an impact crusher relies on energy being conveyed into the rock from the rotor, and it begins with the feed The initial impact is responsible for more than 60% of the crushing action, with the remainder being made up of impact against an adjustable breaker bar and a small amount of interparticle collision2013年11月8日 932 Energy Requirements Major energy sources for limestone and other crushed rock include fuel oil and purchased electricity In 1992, rock mining consumed 668 Btu Table 91 shows the type and quantity of fuels consumed during rock mining as reported by the 1992 US Census of Mineral Industries Crushed Rock 96Limestone and Crushed Rock Department of Energy2017年3月4日 The double jaw crusher is designed for crushing hard materials, also quarried materials, sand and gravel, and recycling [4, 5] crusher [4] The tie rod and compression spring ensure that the (PDF) SIZE REDUCTION BY CRUSHING METHODS

Jaw Crusher an overview ScienceDirect Topics

Michaelson [8] expressed the jaw crusher capacity in terms of the gravity flow of a theoretical ribbon of rock through the open set of the crusher times a constant, k For a rock of SG 265, Michaelson’s equation is given as One of the first important investigations into the distribution of the energy fed into a crusher was carried out by 2016年1月1日 The rock sample is usually screened between close size ranges and the average mass of particles determined The height from which the weight is released to affect breakage is measured The energy of breakage per unit mass is calculated from the expression (320) E = H 00272 M C M ¯ kWh / t = 979 H M C M ¯ Joules / t where E = Size Reduction and Energy Requirement ScienceDirect2016年1月1日 Currently, the dimensions of the largest Blaketype jaw crusher in use are 1600 mm × 2514 mm with motor ratings of 250–300 kW Crushers of this size are manufactured by Locomo, () and others The crusher is the C 200 series having dimensions 1600 mm × 2000 mm driven by 400 kW motors Table 41Jaw Crusher ScienceDirect

Rock Crusher Eastman Rock Crusher

Stone rock crushers are widely used in many sectors such as mining, smelting, building materials, highways, railways, water conservancy, and chemical industriesAt present, there are two types of stone crushing 2018年8月7日 The design and construction of a prototype rock crushing machine was performed this is with a view to ensuring that the designed crusher is capable of crushing rocks, lime stone and solid minerals (PDF) Design and Construction of Rock Crushing 2015年12月26日 In mineral processing or metallurgy, the first stage of comminution is crushing Depending of the type of rock (geometallurgy) to be crushed, there are 2 largely different techniques at your disposition for Crushing in Mineral Processing 911 Metallurgist

ANALYSIS OF ENERGY CONSUMPTION OF CRUSHING

materials energy consumption in the twostage crushing process was reduced by 30% Key words: rock crushing, jaw crusher, crushing efficiency, two stage crushing process 1 INTRODUCTION The main aim of processing rock raw materials is to prepare and process the rocks to a condition that meets the commercial requirements for quality parameters as2020年12月17日 Jaw crushers can be divided into two basic types, single and double toggle In the single toggle jaw crusher, an eccentric shaft is on the top of the crusher Shaft rotation, along with the toggle plate, causes a compressive action A double toggle crusher has two shafts and two toggle plates The first shaft is a pivoting shaft on the top of Crushing 101 – Different types of crushers for distinctive needs2016年1月1日 Primary crushers are solidly built to receive large lumps of rock directly from the mines and designed for large tonnage throughputs Basically, gyratory crushers consist of a fixed solid conical shell or bowl (also called concaves) and a solid cone within the bowl called a breaking head (Figure 51)The breaking head is fixed to a central spindle, which Gyratory and Cone Crusher ScienceDirect

Comminution testing JKTech University of Queensland

The JK Drop Weight Test is a single particle breakage test across 15 size/energy combinations Sample requirements: The minimum sample required to provide sufficient particles for testing is 100 kg of crushed rock in the 63+132 mm size range JKTech can prepare a sample to the specified size range from a larger amount if required2018年10月1日 The comminution process, which includes both crushing and grinding, is one of the world’s most energyintensive industrial processes Comminution uses at least three percent of total global Improving energy efficiency in comminution The purpose of the primary crusher is to reduce the ROM ore to a size amenable for feeding the secondary crusher or the SAG mill grinding circuit The ratio of reduction through a primary crusher can be up to about 8:1 Feed: ROM up to 15 m Product: 300mm (for transport) to 200mm (for SAG mill) Feed Rate:AMIT 135: Lesson 5 Crushing – Mining Mill Operator Training

Crusher Bucket Excavator attachment Big volume Epiroc US

2023年11月3日 Onsite concrete and rock crushing made easy BC bucket crushers are an innovative answer to crushing requirements on today’s worksites Using a rigmounted bucket crusher, all types of inert demolition material can be crushed and reused on site This process requires less mechanical equipment, less transportation and dumpsite cost 2017年6月12日 rock Optimizing blasts to yield smaller rocks would reduce crusher plant energy consumption Some of the methods that can be used to improve the shotrock yields are: Increase the blast hole diameter Use stemming plugs in the blast holes Increase subdrilling depth Use new emerging 3D imaging technologies to develop the blast patternsEnergy Efficiency Opportunities in the Stone and Asphalt 2016年2月24日 Production Requirements The process design criteria define the project’s production requirements, and typically include those shown in Table 1 Table 1 Production requirements Process Description General Ore Characteristics Operating Schedule General Primary crushing Fines crushing Storage reclaim Maximum rock size in the feedCrushing Plant Design and Layout Considerations 911

Predicting the overall specific energy requirement of crushing

2009年5月1日 A cone crusher model is presented that uses the familiar “population balance” framework The model was fitted so that the product particle size distribution can be predicted when operating at the minimum crusher gap CSS A previously developed energy model is applied to the particle size distribution that is the output of the breakage Mixing power (kw): 132160 Total weight (t): 185 Dimension (L×W×H) (mm): 2690×2688×2890 Get Price Now In addition to the above three most common rock crushers, AIMIX also offers different types of equipment such as hammer rock crushers, roller rock crushers, and gyratory rock crushers At the same time, we also provide Rock Crushers For Sale Multiple Types For Your NeedsWhen requirements of this typeC standard are different from those which are stated in typeA or B standards, the requirements of this typeC standard take precedence over the requirements of the other standards for machines that have been designed and built according to the requirements of this typeC standardISO 218732:2019(en), Building construction machinery and

Size reduction control in cone crushers ScienceDirect

2021年11月1日 Fresh feed rate and crusher feeding condition (chokefed/tricklefed) had significant impacts on size reduction of manual control Only automatic control compensated for the effect of feed rate and crusher feeding condition • CSS showed a decreasing trend to compensate for wear (both automatic and manual control) •The cone crusher cannot take material of all sizes The materials must be predimensioned for the crusher (usually 200 mm or less) The finished product is not homogeneous, which is an essential requirement for many material specifications Not suitable for handling clay or metal mixed with rockChoosing the right crusher Buying Guides DirectIndustry2019年9月9日 This next generation crusher features a fully hydraulic gap setting/retraction system which allows for automatic adjustment of the gap, compensation of liner wear and release of tramp metal or otherwise uncrushable material content “The ERC can also crush large hard lumps for example, our ERC 2525 model has a roll diameter of 2500 mm by thyssenkrupp launches nextgen ERC primary crusher

Selecting rock types for verylowcost crushed rock heat

2023年5月1日 Crushed rock is used and proposed for many heat storage systems because the capital costs per unit of sensible heat storage is more than an order of magnitude less than other energy storage media Crushedrock heat storage using air as the heat transfer fluid is a very old technology with many new variants being developed2021年6月10日 Comminution Circuits Are The Single Biggest Energy Consumer At Mines Improving Energy Efficiency Here Is Therefore A Key Part In Improving The LongTerm Financial And Environmental Sustainability Of The Mining Industry By Jonathan Rowland Sustainability is often presented as a challenge for the mining industry – but there are Crushing Energy Efficiency North American Mining Magazine2022年1月23日 The work indices are important for determination of crushing energy requirements and the abrasion index is important for estimating equipment metal wear and grinding media consumption The hardness according to Mohs scale of Gibbsitic and Boehmitic bauxites are typically 1–3, while it ranges from 6½–7 for Diasporic bauxites [ 3 ]Physical Bauxite Processing: Crushing and Grinding of Bauxite

4 Types of Stone Crushers' Maintenance and

2023年2月15日 Horizontal Shaft Impact crusher (HSI) Impact crusher working animation The working principle of impact crusher is that the spinning rotor under the driving of the motor can genetate strong impact 2020年2月5日 The function ofthe rock crusher system was defined to be crushing glacier round to pieces of1~inchesand below3 The functional unit to which the rock crusher was normalized is 1000 shorttons ofcrushed glacier round rock of1~inchesand below All energy and materials consumed, as well as emissions to the environment, were normalized toLife Cycle Assessment of a Rock Crusher ACEEE2 天之前 This page is about the Crusher added by Immersive Engineering For other uses, see Crusher The Crusher is a 3×5×3 multiblock added by Immersive Engineering It is used for crushing ores into grit, which is more efficient than normal smelting Once the blocks are assembled, use the Engineer's Hammer on the center of the front of the longer side Crusher (Immersive Engineering) Official Feed The Beast Wiki

Modelling energy and size distribution in cone crushers

2019年8月1日 In the piston and die test, the breakage energy is measured and the data is then used for calibrating the energy model This paper aims to show how the particle size distribution and the energy model is modelled for a Sandvik Hydrocone crusher using the work by Evertsson, 2000, Lindqvist, 2005, see Fig 1 The paper will also show validation 2016年1月1日 One study [6], which is a collaboration that compares seven mine mill/concentrator operations: four gold and three iron ore mines The average energy needed for seven mines is summarized in figure 2, where the energy requirement is broken down into six components: crushing, grinding, processing, tailings, process water, plant general Energy Consumption in Mining Comminution ScienceDirect13311 Primary Crusher Primary crushers are heavyduty rugged machines used to crush ROM ore of (−) 15 m size These largesized ores are reduced at the primary crushing stage for an output product dimension of 10–20 cm The Crusher an overview ScienceDirect Topics

(PDF) Cone Crusher Performance ResearchGate

2015年5月13日 geometry, crusher dynamics and rock material characteristics Concave, mantle, eccentricity and location of the pivot point together form the chamber resulting motion of the mantle and main shaft 2023年3月2日 Introduction For the 100tph stone crushing plant, the truck transfers the original stone with input size under 500mm into vibrating feeder 380*96, and it transfers the stones to jaw crusher PE 600*900, after first crushing the material gets 65180mm size, and then it goes to second crushing cone crusher 1200, the output (1640mm) of cone Getting To Know The Complete Set Stone Crushing PlantA continuous equipment development programme ensures minimum wear, maximum availability, very low maintenance requirements and extreme flexibility regarding establishment of machine and product parameters IMPACTORS FOR SECONDARY AND HARD ROCK CRUSHINGIMPACT CRUSHERS