عنا

مرحبا هل يمكنني مساعدتك؟

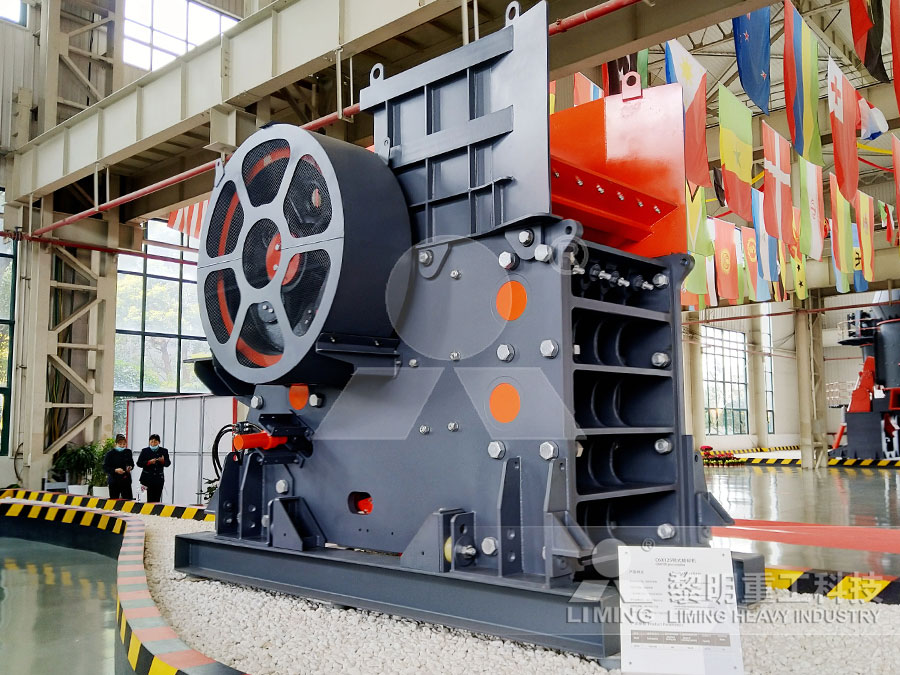

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

Control Of Stroke Of Jaw Crushers

2023-05-17T18:05:52+00:00

Jaw Crusher Handbook Stone Crusher PDF JXSC

Jaw crushers must be started with noload 4 Check that all the instruments are in good condition 5 Check the crushing cavity have or not Minerals 2021年12月1日 The purpose of this research is to develop an automated control system for Jaw crusher production process as a solution for the real specified problems to get more productive aggregateAutomated process control system of Jaw crusher 2016年1月1日 The retrieving action of the jaw from its furthest end of travel is by springs for small crushers or by a pitman for larger crushers As the reciprocating action removes Jaw Crusher ScienceDirect

Jaw Crushers JW Series

2021年2月1日 provides push button control Main shaft The JW Series of single toggle jaw crushers is designed with a tight crushing chamber nip angle and an aggressive 2022年12月12日 The working principle of jaw crusher would help you to understand the machine much better, and the way to maintain the machine would help you to enjoy the What Is the Use and Working Principle of Jaw Crusher?The working principle of jaw crushers is based on the reciprocating movement of the movable jaw that compresses and crushes the rock or ore between itself and the fixed jaw, as the material enters the zone between What Is A Jaw Crusher MEKA

Jaw Crusher SpringerLink

2023年6月21日 The crushing stroke increases gradually from top to bottom along the moving jaw, but with the small upper crushing stroke, the needs of crushing large pieces 2016年1月17日 The maximum feed size is approximately 8 0% of the feed opening The open side setting is measured when the crusher is at rest The setting is measured either top to top, or bottom to top, depending on the Crusher Close Side Settings 911 Metallurgist2021年2月18日 Jaw crushers are so powerful that they’ve earned the moniker “rock breakers” because of their brute force All jaw crushers will have one fixed jaw and a moving one These two form a Vshaped What Is a Jaw Crusher? Here's How It Works

Capacities and performance characteristics of jaw crushers

1994年5月1日 By using the data of EA Hersam and FC Bond’s equation for energy consumption in comminution, a method was developed to analyze the performance of industrial jaw crushers The study showed that industrial jaw crushers are generally operated below capacity The study also showed that industrial jaw crushers generally have 1 天前 The Pioneer ® Series of jaw crushers represents the very latest in jaw crusher technology Engineered to be the highestcapacity jaw crusher on the market, the Pioneer ® Jaw Crusher will deliver up to 25 percent Pioneer® Jaw Crushers Astec2020年8月14日 The Discrete Element Method (DEM) is a numerical method that is able to simulate the mechanical behavior of bulk solids flow using spheres or polyhedral elements, offering a powerful tool for Minerals Free FullText DEM Simulation of

® C Series™ jaw crushers Proven reliability and

2021年7月16日 C Series jaw crushers have a strong pinned and bolted, nonwelded frame aspect when considering the performance of a jaw crusher Our industryleading stroke is amplified from top to bottom, being at its Active Setting Control (ASC) Active Setting Control (ASC) is an optional accessory for the C96™, C106™, C116™ and 2022年3月8日 As a widely used coarse breaking equipment, jaw crusher has a development history of one hundred years At present, there are some differences in the structure, shape, design and materials of jaw crushers in the market Today, we will sort out and analyze the jaw crusher from seven aspects: crushing chamber, frame, discharge 7 Differences of Jaw Crusher Eastman Rock Crusher2020年3月19日 Best suited for secondary crushing applications, cone crushers are designed to crush presized materials, usually 100mm, 150mm or 200mm, depending on the size of the crusher Cone crushers can form finished products down to 12mm or less Like the jaw crusher, the cone crusher provides a relatively low cost crushing solution, but Selecting the right crusher for your operations Quarry

Liner wear in jaw crushers ScienceDirect

2003年1月1日 Abstract Wear in rock crushers causes great costs in the mining and aggregates industry Change of the geometry of the crusher liners is a major reason for these costs Being able to predict the geometry of a worn crusher will help designing the crusher liners for improved performance A model for prediction of sliding wear was 2 天之前 Description A Laboratory Jaw Crusher engineered for precrushing of extremely hard up to brittle materials The 4″ x 5″ 911MPEJC100 Jaw Crusher is designed for batch and continuous crushing of middle hard, hard brittle and tough materials for the following fine grinding Principle of operation of this crusher The Model 100 mm X 130 mm 911MPE Laboratory Jaw Crusher 911 Metallurgist2021年4月16日 Cone head stroke Gyrating speed Manganese liner profile Closed side setting (CSS) Crushing force, monitored as operating pressure Applied power Feed control In any crushing operation, physical characteristics of the material being processed affect the output product The material characteristics that affect the crushing process The pros and cons of cone crusher applications Quarry

® C Series™ jaw crushers

The core of ® C Series™ jaw crusher is a pinned and bolted, nonwelded frame construction that provides excellent fatigue strength All the frame components are casted using an alloy developed inhouse especially for jaw crushers In addition to solid casting, the crushers’ frame has a cellular, so called honeycomb structure that Jaw Crushers; Cone Crushers; Typically, the initial crushing stage is completed using either gyratory crushers or jaw crushers It is often the case that there will be only one crusher installed, and this will be referred to as Gyratory Crusher (Gyratory Crushers Explained)2021年1月1日 This belief seems largely to be due to the features it shares with jaw crushers A jaw crusher can be considered as a twodimensional device as shown in the cross section in Fig 1 The names of its key parameters; open and closed side setting and stroke are easy to see in the cross section There are several types of jaw crusher but the Geometric analysis of cone crusher liner shape

McLanahan Jaw Crushers

The Jaw Crusher was first introduced by Eli Whitney Blake in 1858 as a doubletoggle Jaw Crusher Introduced in 1906, McLanahan’s Universal Jaw Crusher was one of the first modern era overhead eccentric Jaw 2020年6月3日 Adjustments to the discharge opening allow the user to control the final size of the crushed material Jaw crushers are a primary tool for material reduction, and rock quarries, as well as the sand, gravel, mining, construction, metallurgy and chemical industries, use jaw crushers to refine the materialA Detailed Overview of Cone Crushers and What You Need 2020年6月1日 optimize the energy efficiency by optimizing the control model[4] The stroke feature value of outlet is the ratio of vertical displacement to horizontal displacement of swing jaw The stroke feature value of outlet has a great influence on the wear of the crusher When the stroke feature value is large, the wear of liner is heavyThe Optimization of Jaw Crusher with Complex Motion

Industrial Solutions Gyratory crushers ThyssenKrupp

2022年11月21日 The design of our gyratory crushers and jaw gyratory crushers is based on over • Stroke can be changed by adjust ing the eccentricity sate for wear • Low operating and maintenance costs • Includes “Gyramatic” control system KB 5467 KB 6375 BK 5467 KB 6389 BK 6375 KB 63130 KB 5475 KB 63114 thyssenkrupp, range of 2020年7月24日 C Series jaw crushers have a strong pinned and bolted, nonwelded frame aspect when considering the performance of a jaw crusher Our industryleading stroke is amplified from top to bottom, being at its Active Setting Control (ASC) is an optional accessory for the C96™, C106™, C116™ and C120™ models ThisEngineered for the toughest feed materials ® 2023年1月5日 The jaw crusher works by using a moving jaw and a fixed jaw to crush and grind the rocks The material is fed into the jaw crusher by a vibrating feeder, and then it is crushed between the two jaws The jaw crusher is made up of several parts, including a fixed jaw, a moving jaw, and a toggle plate The fixed jaw is mounted to the frame of the How Does a Jaw Crusher Work? Industrial Technology

® C Series™ jaw parts

2018年10月15日 the jaw dies in an upwards direction during the compressive stroke of the pitman C Series™ jaw crusher basic concepts The jaw crusher is a compression type crusher Feed material is crushed between fixed and movable jaw dies Large particles are crushed in a single layer, referred to as singlelayer crushing Smaller2016年1月17日 The maximum feed size is approximately 8 0% of the feed opening The open side setting is measured when the crusher is at rest The setting is measured either top to top, or bottom to top, depending on the tooth profile of the jaw dies The closed side setting can be calculated by deducting the stroke from the OSSCrusher Close Side Settings 911 MetallurgistJawcrusher Construction Jaw crushers are heavyduty machines and hence must be robustly constructed The main frame is often made from cast iron or steel, connected with tiebolts It is commonly made in sections so that it can be transported underground for installation Modern jaw crushers may have a main frame of welded mild steel plateJaw Crusher an overview ScienceDirect Topics

What Are Jaw Crushers and How Do They Work?

March 28, 2019 / in News A jaw crusher is a large piece of equipment that’s used in mine and ore processing plants to crush rocks The equipment was first introduced back in 1858 by inventor Eli Whitey Black who primarily 2023年3月14日 The main characteristic of jaw gyratory crushers is their enlarged feed opening, which is located on one side of the crusher only Jaw gyratory crushers can handle much bigger chunks of material than comparable gyratory crushers of the same mantle diameter Jaw gyratory crushers feature a higher crushing ratio and less tendency to Product datasheet Jaw Gyratory Crusher BK 6375 Pro2022年1月21日 The automatic feed rate control helps to maintain the optimal material level in the crusher, which helps you to achieve and maintain the best performance at all times HP cone crushers can also be delivered without crusher automation and operated manually or directly through plant automation Remote control improves operator safety and comfort HP Series cone crushers – High performance

RIVLQJOH WRJJOHMDZ FUXVKHU

Singletoggle jaw crushers are used at the beginning of this process [7] and are among the main machines for crushing Jaw crushers are widely used in many different industries to crush brittle materials with various strength Usually, jaw crushers are put at the beginning of the technological lines of oredressing and sample cutting2023年6月2日 ® C Series™ jaw crushers have proven to be reliable and productive in thousands of mining, quarrying, recycling and industrial applications with up to 11,000 jaw crusher installations since 1975 Developed to crush the hardest ores and rocks, jaw crushers also perform outstandingly with less demanding materialsProven reliability and performance ® C 2020年6月1日 The stroke of the crusher was constant at 30 mm, while three CSS were used: 40 mm, 70 mm, and 100 mm The normal speed for the crusher was 355 rpm A reduced speed of 284 rpm was also tested, corresponding to a 25% reduction Another possibility is to include other jaw crushers to assess the effect of crusher geometry 5 Influence of jaw crusher parameters on the quality of

Crusher an overview ScienceDirect Topics

13311 Primary Crusher Primary crushers are heavyduty rugged machines used to crush ROM ore of (−) 15 m size These largesized ores are reduced at the primary crushing stage for an output product dimension of 10–20 cm The 1999年12月1日 With this assumption there is no time left for the crushing stroke Modelling of flow in cone crushers 1497 A second and different way of calculating the number of strokes is to use the measured capacity and back calculate the mean velocity 10(2), 199214 Gauldie, K, Performance of Jaw Crushers Engineering, October 9, 1953, 456458 Modelling of flow in cone crushers ScienceDirect2023年7月14日 The mainframe and swing jawholder are protected from wear due to the design of the jawholder that completely protects the inlet and outlet points of the crushing chamber Replaceable backing plates protect the jawface support locations At the top of the jawholder, a guard protects the bearing housing A comprehensive range of jawface Minerals Processing Systems JW SERIES JAW

Jaw crusher EB

Our Jaw Crusher EB series offers you the following benefits: With the Jaw Crusher EB series, you benefit of the highest performance, which leads to 10% higher throughput rates thanks the optimised nip angle and 2021年2月18日 Jaw crushers typically use the principles of compression and friction to break materials down They’re extremely powerful equipment that should be used with the utmost care Jaw crushers are so powerful What Is a Jaw Crusher? Here's How It Works2021年1月10日 A jaw crusher is one of several types of crushers, including impactors, hammermills, and cone crushers, that are manufactured for the purpose of processing aggregate minerals, RAP, and recycled concrete What Is a Jaw Crusher and What Can It Do for You?

New cone and jaw crusher designs Springer

2017年8月28日 Manual control of the gap between the jaws is by means of a handwheel The setting Jaw crushers with two jaw openings can be considered to be a completely new design Jaw crushers are distinguished by reciprocating and complex movement of the moving jaw movement of the movable jaw relative to the stationary one is such that its 2019年7月24日 The single toggle jaw crusher has fewer bearings and shafts as compared to a double toggle jaw crusher It has more planes of movement of the swinging jaw (Hinge door movement plus vertical up and down movement) which leads to higher throughput On the downside, it produces more fines, and has a higher jaw plate consumption Uses one Difference between Double and Single Toggle Jaw Crusher2021年11月22日 Jaw crushers include Superior, Type “B” Blake, FineReduction, and Dodge — sizes, 4 by 6 to 84 by 66 inches A reciprocating machine, the crushes material in a straight line between jaws — without grinding or rubbing surfaces Adjustable crushing stroke is provided by means of simple shims Toggle block shims provide maximum How does a Rock Crusher Work Jaw Crusher 911

Liner wear in jaw crushers Request PDF ResearchGate

2003年1月31日 Abstract Wear in rock crushers causes great costs in the mining and aggregates industry Change of the geometry of the crusher liners is a major reason for these costs Being able to predict the 2016年1月1日 Currently, the dimensions of the largest Blaketype jaw crusher in use are 1600 mm × 2514 mm with motor ratings of 250–300 kW Crushers of this size are manufactured by Locomo, () and others The crusher is the C 200 series having dimensions 1600 mm × 2000 mm driven by 400 kW motors Table 41Jaw Crusher ScienceDirect2019年8月24日 Rollers or jaw crushers are employed in this situation The jaw crusher is a rocks or lumps reduction machine that employs two hardened manganese steel jaws, with one in the tremendous crushing force to each stroke The moveable jaw stock comprises of the grease drum and the part where the high manganese steel die (jaw) is fixed Design and Construction of Rock Crushing Machine from

Jaw Crushers JW Series

2021年2月1日 provides push button control Main shaft The JW Series of single toggle jaw crushers is designed with a tight crushing chamber nip angle and an aggressive crushing stroke to maximize productivity The accompanying table gives typical outputs for our range of machines, based on dry, free flowing material 1994年5月1日 By using the data of EA Hersam and FC Bond’s equation for energy consumption in comminution, a method was developed to analyze the performance of industrial jaw crushers The study showed that industrial jaw crushers are generally operated below capacity The study also showed that industrial jaw crushers generally have Capacities and performance characteristics of jaw crushers1 天前 The Pioneer ® Series of jaw crushers represents the very latest in jaw crusher technology Engineered to be the highestcapacity jaw crusher on the market, the Pioneer ® Jaw Crusher will deliver up to 25 percent Pioneer® Jaw Crushers Astec

Minerals Free FullText DEM Simulation of

2020年8月14日 The Discrete Element Method (DEM) is a numerical method that is able to simulate the mechanical behavior of bulk solids flow using spheres or polyhedral elements, offering a powerful tool for 2021年7月16日 C Series jaw crushers have a strong pinned and bolted, nonwelded frame aspect when considering the performance of a jaw crusher Our industryleading stroke is amplified from top to bottom, being at its Active Setting Control (ASC) Active Setting Control (ASC) is an optional accessory for the C96™, C106™, C116™ and ® C Series™ jaw crushers Proven reliability and 2022年3月8日 As a widely used coarse breaking equipment, jaw crusher has a development history of one hundred years At present, there are some differences in the structure, shape, design and materials of jaw crushers in the market Today, we will sort out and analyze the jaw crusher from seven aspects: crushing chamber, frame, discharge 7 Differences of Jaw Crusher Eastman Rock Crusher

Selecting the right crusher for your operations Quarry

2020年3月19日 Best suited for secondary crushing applications, cone crushers are designed to crush presized materials, usually 100mm, 150mm or 200mm, depending on the size of the crusher Cone crushers can form finished products down to 12mm or less Like the jaw crusher, the cone crusher provides a relatively low cost crushing solution, but 2003年1月1日 Abstract Wear in rock crushers causes great costs in the mining and aggregates industry Change of the geometry of the crusher liners is a major reason for these costs Being able to predict the geometry of a worn crusher will help designing the crusher liners for improved performance A model for prediction of sliding wear was Liner wear in jaw crushers ScienceDirect2 天之前 Description A Laboratory Jaw Crusher engineered for precrushing of extremely hard up to brittle materials The 4″ x 5″ 911MPEJC100 Jaw Crusher is designed for batch and continuous crushing of middle hard, hard brittle and tough materials for the following fine grinding Principle of operation of this crusher The Model 100 mm X 130 mm 911MPE Laboratory Jaw Crusher 911 Metallurgist

The pros and cons of cone crusher applications Quarry

2021年4月16日 Cone head stroke Gyrating speed Manganese liner profile Closed side setting (CSS) Crushing force, monitored as operating pressure Applied power Feed control In any crushing operation, physical characteristics of the material being processed affect the output product The material characteristics that affect the crushing process The core of ® C Series™ jaw crusher is a pinned and bolted, nonwelded frame construction that provides excellent fatigue strength All the frame components are casted using an alloy developed inhouse especially for jaw crushers In addition to solid casting, the crushers’ frame has a cellular, so called honeycomb structure that ® C Series™ jaw crushers