عنا

مرحبا هل يمكنني مساعدتك؟

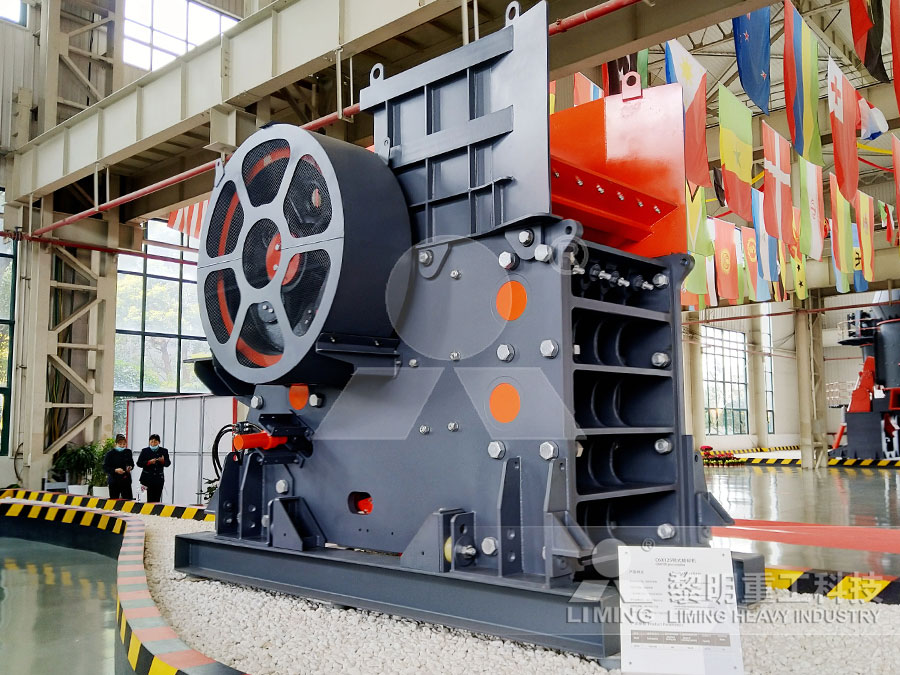

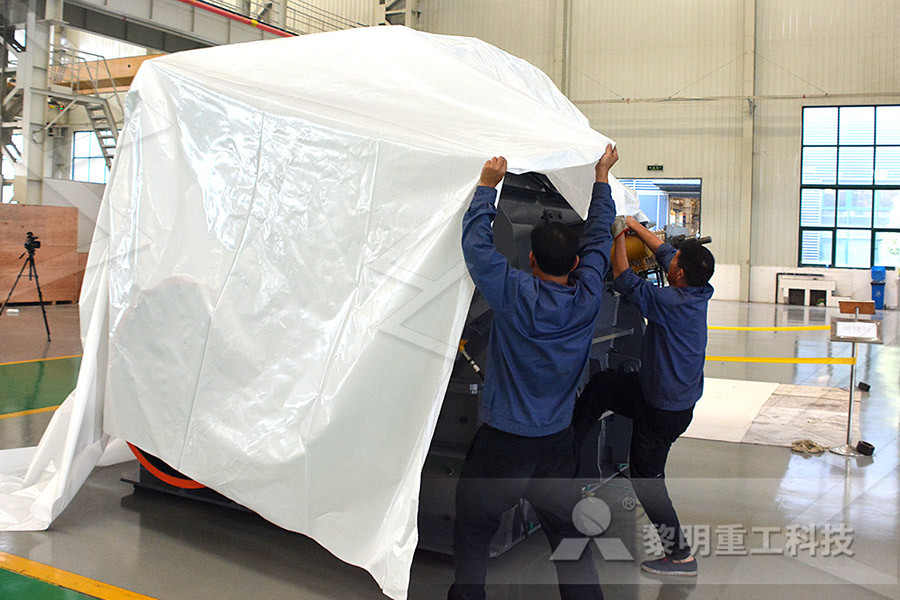

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

cement vertical roller mill in russia

2023-11-03T04:11:34+00:00

Review on vertical roller mill in cement industry its

2021年1月1日 In the study the advantages of vertical roller mill are discussed over ball mills VRM construction, its process and parameters which affects the performance and Lafarge Cement decided to use a grinding plant with a Pfeiffer vertical roller mill in its Ferzikovo plant in Russia The MPS 5300 BC with a drive power of 5500 kW will produce Cement mill for Lafarge in Russia Cement Lime Gypsum ZKGThe vertical roller mill (VRM) is a type of grinding machine for raw material processing and cement grinding in the cement manufacturing process In recent years, the VRM cement Vertical Roller Mill Operation in Cement Plant

Review on vertical roller mill in cement industry its

2021年1月1日 For the past three decades the vertical roller mill has emerged to be the preferred choice for grinding raw materials With the grinding capacity of a vertical roller 2022年5月9日 In the mid1990s, the vertical roller mill (VRM) was introduced to the cement industry to reduce this energy usage Besides lowering power consumption, VRMs may Modeling of energy consumption factors for an industrial cement In this paper, a system integration updated technology for a largescale raw material vertical roller mill is introduced, which was developed originally by the Tianjin Cement Industry Industrial application of system integration Cement Lime

The important role of vertical roller mills in the cement industry

1 Separator is an efficient and energysaving powder selection device 2 Grinding roller is used to grind and crush materials 3 The grinding table is fixed on the output shaft of the The vertical roller mill grinding system, roller press mill grinding system and ball mill grinding system are all for raw material preparation in the cement production line AGICO Cement manufactures highquality vertical roller Comparison Of Cement Vertical Roller Mill And 2 天之前 HRM vertical mill series vertical mills are widely used in different industries such as cement, electricity, metallurgy, chemical and nonmetal mineral for the grinding of cement raw meal, clinker, mining slag, steel Vertical Roller Mill China Vertical Roller Mill and

Ball Mill for Sale Mining and Cement Milling

1500t/d Continuous Ball Mill for Copper Mining in Pakistan Production capacity: 1500t/d Processed material: Copper ore Input size: ≤25mm Equipment: 98386t/h copper ball mill, jaw crusher, cone crusher, Gearbox replacement on a vertical roller mill by Cementos La Cruz Azul*) selves as well as on the ancillary equipment, such as the lubrication unit As a result, the installation of a MAAG lubrication system is advantageous due to its higher level of operational reliability and lower maintenance requirements Fig 2 shows a schematic representation of the MAAG Gearbox replacement on a vertical roller mill by2022年1月23日 This work concentrates on the energy consumption and grinding energy efficiency of a laboratory vertical roller mill (VRM) under various operating parameters For design of experiments (DOE), the Analysis and Optimization of Grinding

Vertical Roller Mill China Vertical Roller Mill and Vertical

2 天之前 Company Introduction: CNBM Hefei Zhongya Building Material Equipment Co, Ltd is a technologyoriented enterprise with the integration of research development, engineering design, equipment manufacture and technical service, which was established by professional scientific technical personnel engaged in research of vertical mill from 2019年10月11日 The two most common compressive comminution technologies are the high pressure grinding roller (HPGR) and the verticalrollermill (VRM) For now, the HPGR has already presented in a noteworthy number of mining projects whereas VRM technology, a new entrant, is still not fully accepted This is considered a resistance to change Vertical roller mills: The new leader in grinding technology2022年4月6日 An interesting historical fact is that a vertical roller mill uses the same operating principle as the pistrium or pistrinum, an antique Roman grain millThe largest grain mills used worked a Chapter Six: Some Operating Guidelines Vertical Roller Mill

Vertical Roller Mill Operation in Cement Plant

The vertical roller mill (VRM) is a type of grinding machine for raw material processing and cement grinding in the cement manufacturing processIn recent years, the VRM cement mill has been equipped in more and more cement plants around the world because of its features like high energy efficiency, low pollutant generation, small floor area, etc The 2023年10月25日 Keywords: Vertical roller mill, cement grinding, performance evaluation INTRODUCTION Cement production is highly energy consuming process with energy utilization of around 110150 kWh/t (Villa,Performance Evaluation of Vertical Roller Mill in Cement 2016年1月4日 Vertical roller mills are adopted in 20 cement plants (44 mills) in Japan Results Table Energy saving effect of the vertical roller mill Ball mill Specific power Cost estimation About 14million US$ [Newlybuilt] and about 230 million US$ [retrofitted], including the cost of supplemental facilities [200tRM/h] [1US$=¥110] Related matters Vertical roller mill for raw Application p rocess materials

(PDF) Capacity of roller mill for cement grinding

2020年12月15日 Simmons M, Gorby L, Terembula J Operational experience from the United States' first vertical roller mill for cement grinding 2005 IEEE Cement Industry Technical Conference Conference Record 2023年11月3日 During the height of the COVID19 pandemic, Welding Alloys undertook a project to repair a vertical roller mill (VRM) at Hanson Cement’s site in Purfleet, Essex The work involved the repair of a Vertical roller mill Welding Alloys2023年10月3日 Since 1906 worldwide market leader in designing, manufacturing and servicing vertical roller mills for the cement, power and industrial minerals industriesPlant engineering solutions for any mission

(PDF) Drives for large vertical roller mills

2017年1月1日 1012 Bo Bentsen Bentsen, Bo: The unique high energy efficient OK cement mill Presentation at 20 th Arab International Cement Conference and Exhibition, 1012 November 2015, Cairo/Egypt Drive 2019年4月10日 OK™ cement mill If you are looking for a reliable and efficient cement grinding solution, you may want to consider the OK™ cement mill This brochure introduces you to the features and benefits of this vertical roller mill, which can handle a wide range of cement types and capacities Learn how the OK™ cement mill can help you OK™ cement mill The most energy efficient mill for 2019年12月2日 Although ball mills were first introduced in the 1860’s, the main progress was made during the 1870’s to 1900’s in Germany, where its growing cement and chemical industries increased the Cement Finish Milling (Part 1: Introduction History)

Modeling of energy consumption factors for an

2022年9月12日 In the mid1990s, the vertical roller mill (VRM) was introduced to the cement industry to reduce this energy usage Besides lowering power consumption, VRMs may improve process capacity2017年9月11日 Due to the compact design and material transportation system of vertical roller mills (VRM), some important streams (total mill feed and discharge, dynamic separator feed and reject) remain in the (PDF) Performance Evaluation of Vertical Roller Mill in Cement The quadropol® concept for coal or pet coke grinding, with adapted table speed and high efficiency separator sepol®, ensures a safety mill operation and serves reliable the kiln burning process Mombasa Cement Ltd ordered a QMK² 24/12 with three roller units for the 5,000 tons per day kiln linequadropol® vertical roller mill thyssenkrupp Polysius

China Vertical Roller Mill Manufacturer, Vertical Roller Mill

CNBM Hefei Zhongya Building Material Equipment Co, Ltd is a technologyoriented enterprise with the integration of research development, engineering design, equipment manufacture and technical service, which was established by professional scientific technical personnel engaged in research of vertical mill from Hefei Cement Research 2023年11月3日 24 202310 Rotary kiln parts professional custom manufacturers Great Wall Machinery is a rotary kiln and mill supplier, and can provide all kinds of accessories for cement factories, we have our cement plant,ball mill,vertical mill,rotary kiln,slag The third production line of YongDeng Qilianshan Cement Co, Ltd was updated and put into production in 2010, the raw material mill of which is the TRM534 vertical mill The vertical mill output is 500t/h and the product R 80μm is 12% The vertical mill system has defects such as a large mill pressure difference and a high system negative Industrial application of system integration Cement Lime

EVALUASI KINERJA VERTICAL ROLLER MILL (Cement Mill)

2023年11月2日 Pada Vertical Cement Mill terjadi empat proses yang berlangsung secara simultan Keempat proses tersebut yaitu penggilingan, pengeringan, transport, dan separasi Proses penggilingan, pengeringan MVR vertical mill with conventional drive: economical solution for small to medium output rates For the preparation of cement raw material, cement, and granulated blastfurnace slag with small to medium output rates, the MVR mill with conventional drive is the right choice This mill type is by the way the core piece of our modular ready2grind Cement mills and raw mills for small to medium throughput 2023年10月3日 Vertical Roller Mill (VRM) is a type of grinding equipment used to grind materials into extremely fine powder for use in mineral dressing processes, paints, pyrotechnics, cements, and ceramics It Vertical Roller Mill for Cement Market Research Report

Gear units to fit your vertical roller mill

Our comprehensive line of gear for vertical roller mills excels in many applications, including coal or raw material comminution and cement grinding With power output ranging from a few 100kW to over 10MW, we have the drive solutions and gear units to meet your needs – and optimise your production Products Services2015年7月29日 VRM optimisation Most new cement plants utilise vertical roller mills (VRM) for raw material grinding and preparation Taking a stepbystep look at the entire roller milling process, Kline Consulting recommends routine measurements and discusses ways to overcome chemical issues to optimise operations • incorporation of drying with VRM optimisation International Cement Review2013年2月26日 Ball mills are built at the supplier’s factory and transported to the cement producer’s site In contrast, the vertical mill is built onsite at the cement plant, avoiding difficult logistical issues and associated costs The equipment costs are higher for a VRM than a ball mill, reflecting the greater complexity of the system, which Comparing ball mills and VRMS for cement grinding

Grinding process optimization IEEE Xplore

2017年6月19日 Abstract: As a worldwide leader in grinding solutions for the cement industry and understanding the changing needs of cement producers and how to tailor solutions to meet those needs Optimizing output, improving efficiency, and reducing CO2 emissions while keeping investment costs to a minimum are common challenges that the 2022年10月1日 Vertical roller mills (VRM) are widely used to grind, dry, and select powders from various materials in the cement, electric power, metallurgical, chemical, and nonmetallic ore industries For the sectors above, the VRM is a powerful and energyintensive grinding field [1], [2] It is used to grind slag, nonmetallic ore, and other block A cement Vertical Roller Mill modeling based on the number The OK™ Mill is offered in a complete size range, including 3, 4 and 6roller mills, and the largest vertical roller mill size available with installed power over 11 500 kilowatts This ensures the ability to meet all possible capacity requirements in a Our modern vertical roller mill takes you further

Coal mill, gypsum mill, clay mill, etc Pfeiffer MPS

MPS 100 GC vertical roller mill for the grinding, drying and calcining of gypsum, Trevo, Brasil MPS 3350 B mill for limestone grinding, China Chongqing Foreign Trade Huaneng, China MPS 5000 B mill for raw 2021年1月28日 This paper deals in first place with roller mills for raw material processing For grinding coal, slag, cement, etc, adaptations to mills and systems have to be made 2 FUNCTIONS OF THE ROLLER MILL The vertical roller mill fulfills 4 main functions in one compact piece of equipment: ¢ Grinding « Drying ¢ Separation ¢ TransportHolderbank Cement engineering book Archive2022年7月26日 The intergrinding of PortlandLimestone Cement (PLC) with Vertical Roller Mills avoids excessive limestone surface area Limestone Cement (ASTM C595 and EN 1971) Requirement Product Characteristics High increase in early and final strength Increase powder flowability SikaGrind®700CEMENT SikaGrind® FOR VERTICAL ROLLER MILLS

VERTICAL ROLLER MILLS AMCL

2020年8月13日 UBE Machinery Corporation Ltd (UBE) has been supplying Vertical Mills for the last 60 years UBE Mills are energy efficient and easy to operate maintain The Mills are available in wide range of capacity for all the applications UBE has been pioneers in cement and slag grinding where “2Way System”is applied to2017年8月12日 The drive of a vertical roller mill – essentially the mill gearbox – has to fulfill two tasks: The first is to reduce the speed of power requirements of cement and slaggrinding mills has been steadily increased For example, in 2006 mill capacities of about 220 t/h equated to 5500 kW of maximum power demand Nine yearsDRIVE SELECTION FOR LARGE LOESCHE VERTICAL 2021年1月29日 FlyAsh Blaine: Increase fly Ash Blaine from 290 to 320 Flyash is a major supply for any cement plant now a days because every producer wants to produce more PPC than OPC due to profitability (PDF) Increase productivity of vertical roller mill

Research of iron ore grinding in a verticalrollermill

2015年3月15日 Verticalrollermills (VRM) are an energyefficient alternative to conventional grinding technology One reason is the dry inbed grinding principle Results of extensive test works with two types of magnetite iron ores in a Loesche VRM are presented here Within these test works, mill parameters like grinding pressure, separator speed 2023年9月25日 Written by Global Cement staff 25 September 2023 Print Uganda: President Yoweri Kaguta Museveni has officially commissioned a new vertical roller mill at Tororo Cement’s plant in Tororo The Germanbuilt mill cost US$25m and can produce 150t/hr of cement The operator claims it to be the ‘most sophisticated’ in East and President launches vertical roller mill at Tororo CementHowever, the unit cost for wear parts for a ball mill is much lower than for a vertical roller mill For a ball mill grinding OPC to a fineness of 3200 to 3600 cm2/g (Blaine) the cost of wear parts (ball, liners and mill internals) is typically 015020 EUR per ton of cementCement grinding Vertical roller mills VS ball mills

Ball Mill for Sale Mining and Cement Milling

1500t/d Continuous Ball Mill for Copper Mining in Pakistan Production capacity: 1500t/d Processed material: Copper ore Input size: ≤25mm Equipment: 98386t/h copper ball mill, jaw crusher, cone crusher, Gearbox replacement on a vertical roller mill by Cementos La Cruz Azul*) selves as well as on the ancillary equipment, such as the lubrication unit As a result, the installation of a MAAG lubrication system is advantageous due to its higher level of operational reliability and lower maintenance requirements Fig 2 shows a schematic representation of the MAAG Gearbox replacement on a vertical roller mill by2022年1月23日 This work concentrates on the energy consumption and grinding energy efficiency of a laboratory vertical roller mill (VRM) under various operating parameters For design of experiments (DOE), the Analysis and Optimization of Grinding

Vertical Roller Mill China Vertical Roller Mill and Vertical

2 天之前 Company Introduction: CNBM Hefei Zhongya Building Material Equipment Co, Ltd is a technologyoriented enterprise with the integration of research development, engineering design, equipment manufacture and technical service, which was established by professional scientific technical personnel engaged in research of vertical mill from 2019年10月11日 The two most common compressive comminution technologies are the high pressure grinding roller (HPGR) and the verticalrollermill (VRM) For now, the HPGR has already presented in a noteworthy number of mining projects whereas VRM technology, a new entrant, is still not fully accepted This is considered a resistance to change Vertical roller mills: The new leader in grinding technology2022年4月6日 An interesting historical fact is that a vertical roller mill uses the same operating principle as the pistrium or pistrinum, an antique Roman grain millThe largest grain mills used worked a Chapter Six: Some Operating Guidelines Vertical Roller Mill

Vertical Roller Mill Operation in Cement Plant

The vertical roller mill (VRM) is a type of grinding machine for raw material processing and cement grinding in the cement manufacturing processIn recent years, the VRM cement mill has been equipped in more and more cement plants around the world because of its features like high energy efficiency, low pollutant generation, small floor area, etc The 2023年10月25日 Keywords: Vertical roller mill, cement grinding, performance evaluation INTRODUCTION Cement production is highly energy consuming process with energy utilization of around 110150 kWh/t (Villa,Performance Evaluation of Vertical Roller Mill in Cement 2016年1月4日 Vertical roller mills are adopted in 20 cement plants (44 mills) in Japan Results Table Energy saving effect of the vertical roller mill Ball mill Specific power Cost estimation About 14million US$ [Newlybuilt] and about 230 million US$ [retrofitted], including the cost of supplemental facilities [200tRM/h] [1US$=¥110] Related matters Vertical roller mill for raw Application p rocess materials

(PDF) Capacity of roller mill for cement grinding

2020年12月15日 Simmons M, Gorby L, Terembula J Operational experience from the United States' first vertical roller mill for cement grinding 2005 IEEE Cement Industry Technical Conference Conference Record